Overview

Inquiry

Related Products

Whole factory plastic parts automatic dust coating equipment

Whole plant metal products electrostatic coating equipment

Whole factory furniture electrostatic coating equipment

Whole plant locomotive, motorcycle coating equipment

Manipulator, Spraying robot etc Industrial Robot equipment

Automatic UV curing furnace line

Fully automatic electrostatic dust removal equipment

DISK automatic electrostatic coating equipment

All kinds of Drying,silk-screen equipment

All kinds of PVC/SUS belt,Nylon conveyor equipment

Teflon/Ceramic powder /PE immersion high temperature equipment

All kinds of Water Curtain Booth etc equipment

High level Air Supply System

Waste water/waste gas recycling system

Whole plant electroplating coating equipment

Whole factory electrophoresis coating equipment

Xinqinfeng

Customized UV Curing Equipment Automatic Spray Painting device is a device that a must-have for those to the artwork industry. The apparatus is established specifically to supply durable and paint is durable for industrial and tasks are commercial.

This automated spray artwork machine comes with personalized UV curing gear that ensures your paint is dry and hardened within seconds. This revolutionary product makes use of ultraviolet light to cure the paint, supplying a durable finish that'll not scrape or peel through the lime easily unlike traditional artwork practices.

The device is fully automatic, rendering it simple to help you take advantage of. All you have to do is load your painting project onto the machine, set the parameters, and permit it to accomplish its job. This process is certainly automatic down from the sometime labor essential to finish a task, making the task faster and more efficient.

At Xinqinfeng, we understand that every artwork project is significantly defend, so in retrospect you can expect fully options that can be tailor made. The equipment is modified for you personally that can be specific such as the size and rate associated with the machine. Whether you're painting little parts or gear is big industrial we can modify the gear to fit your needs.

Another function is certainly very good of item its energy-saving function. It is made to focus on minimal energy, reducing your energy bills. The UV aspect is curing of gear normally an option this certainly eco-friendly because it makes use of no solvents or other harmful chemicals. This particular feature makes it perfect for companies are seeking to lessen their carbon footprint and stick to initiatives are green.

Production Features:

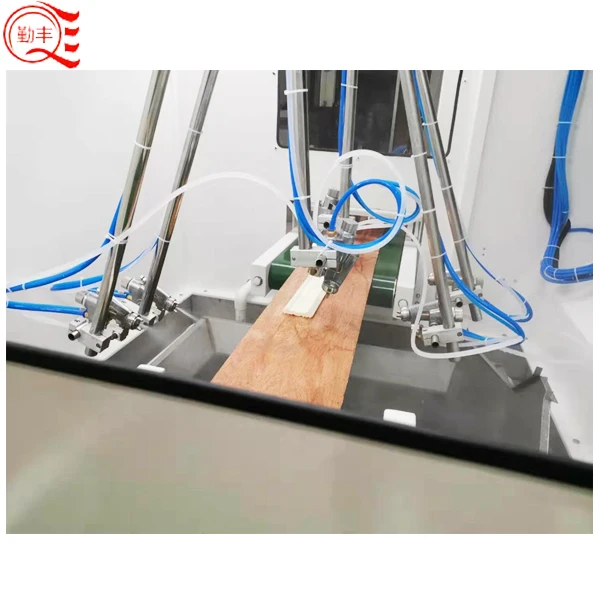

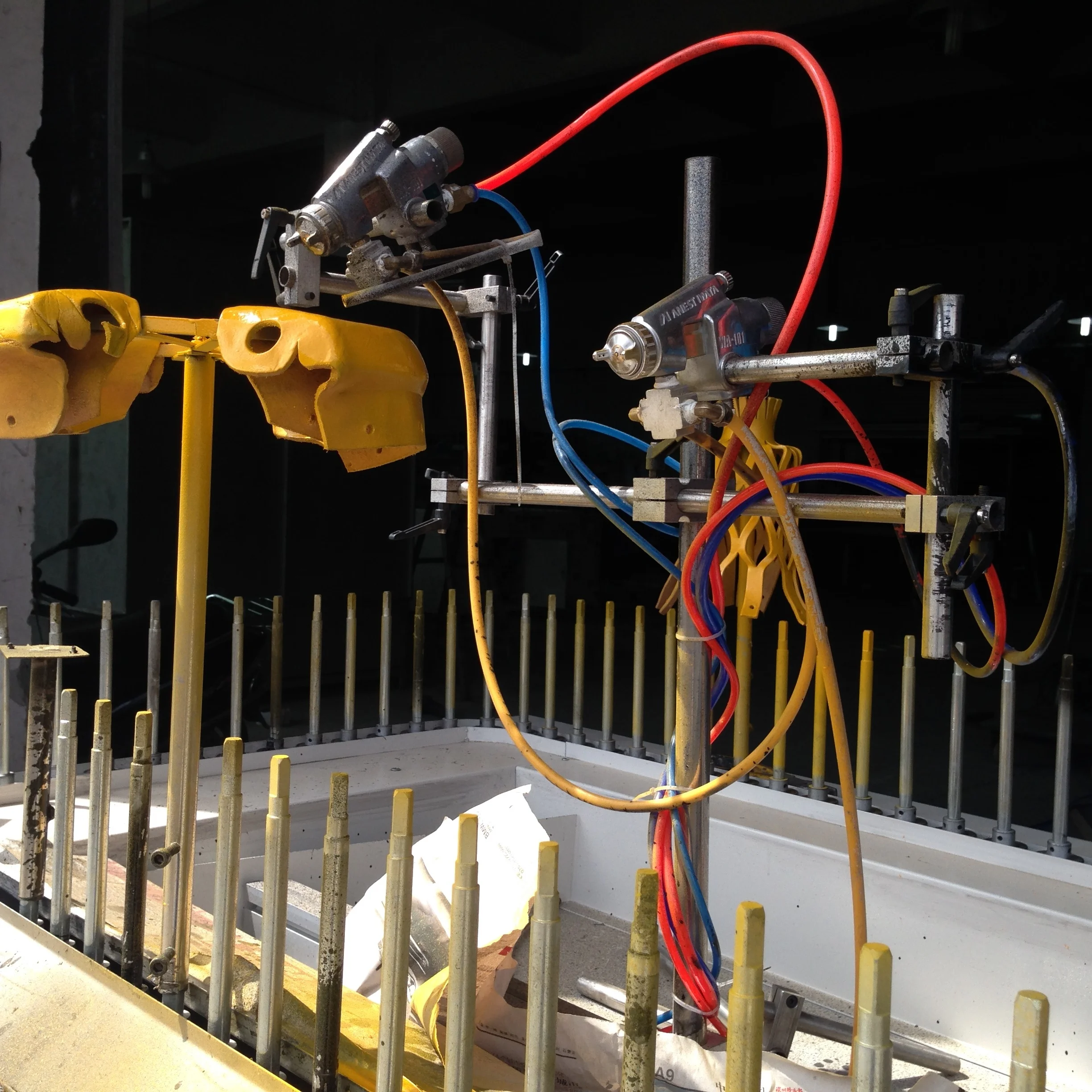

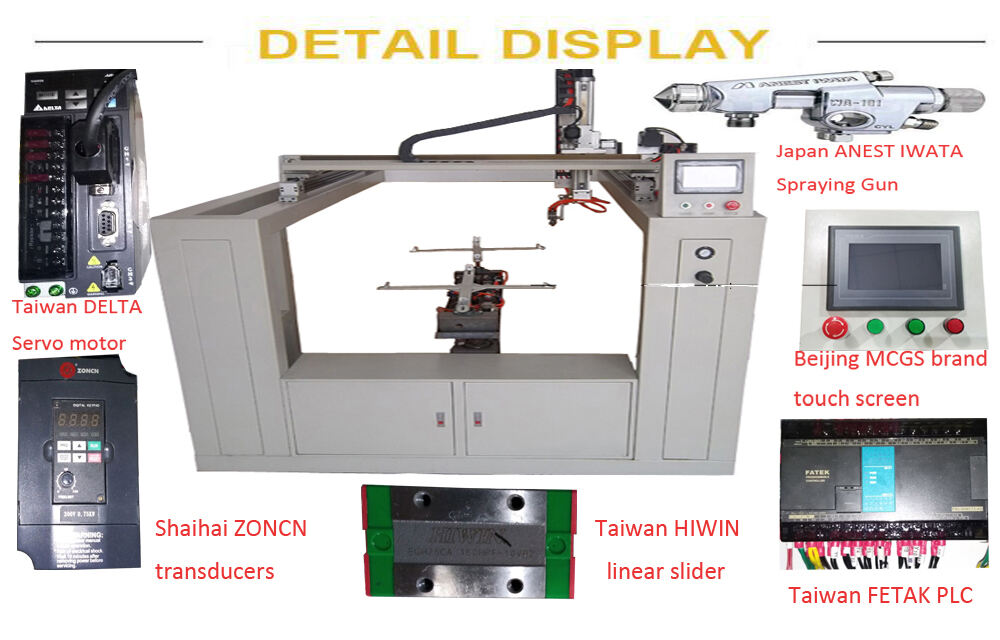

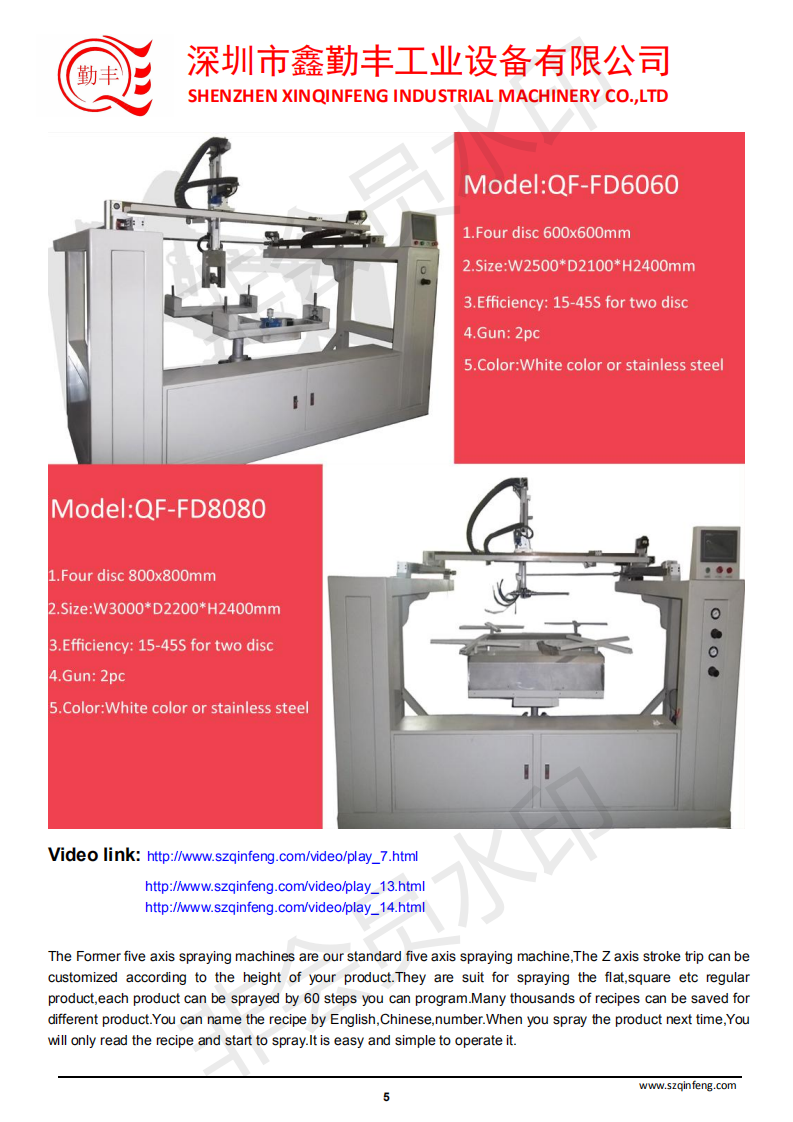

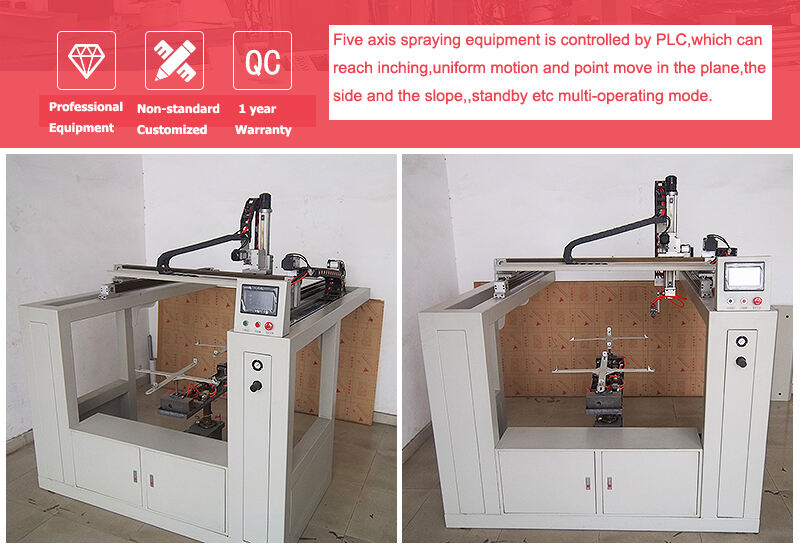

The five axis reciprocating spraying machine with air spraying system will help you get a good coating film and reduce the manual cost. The details of automatic five axis spraying machine are as follows.

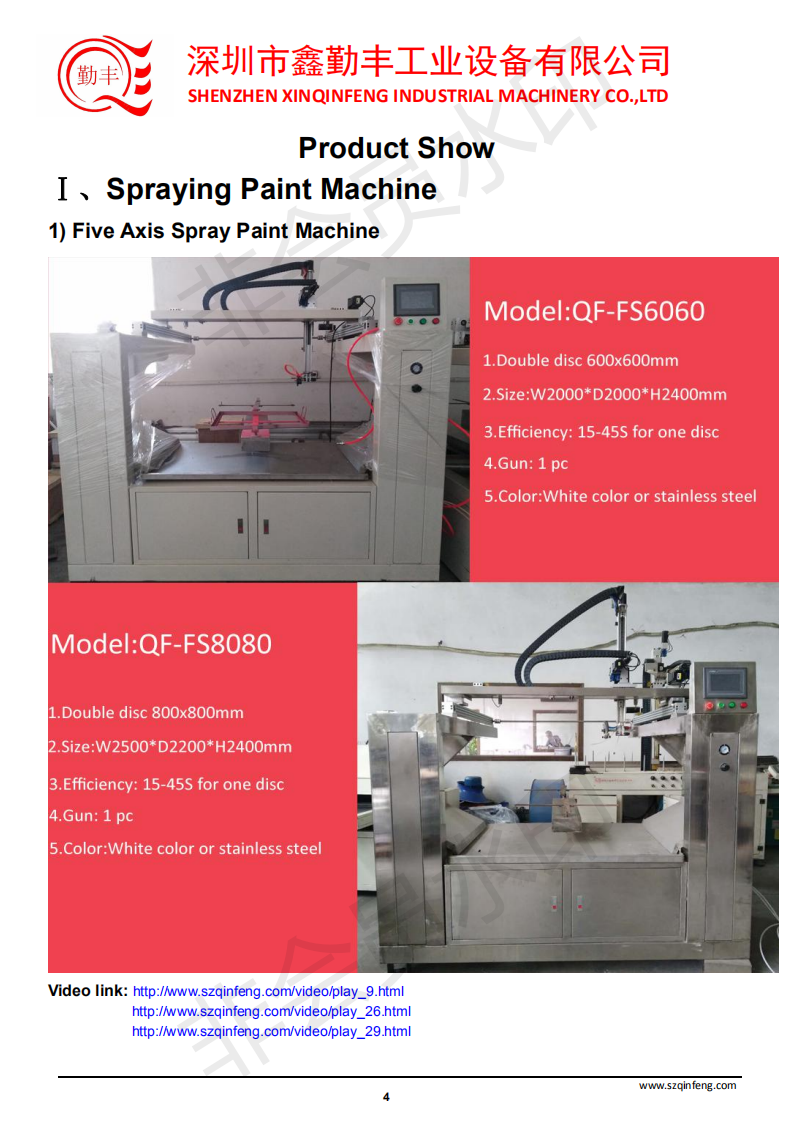

1. This machine is widely used in many industry. Generally speaking, standard type of this machine has two product tray. If you want to buy a machine with four product tray, then you will get double yield under the premise of high quality coating.

2. It is easy to debug the machine. You can finish debugging for usual product in 15 minutes. The program writing of machine is regard one plane of product as a program segment. When you finish setting the start point, end point and the spraying speed, then you have finished a program segment. After finish every program of plane, then the complete program is finished.

3. This machine has continuous spraying method and step spraying method.

4. The atomization and sector, painting output of spray gun can be controlled by computer. When the machine begin to spray, the spray gun can blow, in order to blow dust.

5. It is easy to use this machine, and you can store 160 programs of product. The machine operated by fully digital computer.

Product Specification:

SPECIFICATIONS FOR FIVE AXIS MACHINE | ||

Control system

| 1. The PLC use TAIWAN FATEK Brand 4.The switching power supply use the Taiwan MEANWELL power 5.The Proximity switch and reply use the Japan OMRAON brand | |

Aluminum profile module | Our own mold | |

Drive system | The servo motor driving use Taiwan DELTA brand | |

| 1.Aluminum profile module 6.Rack and pinion drive | |

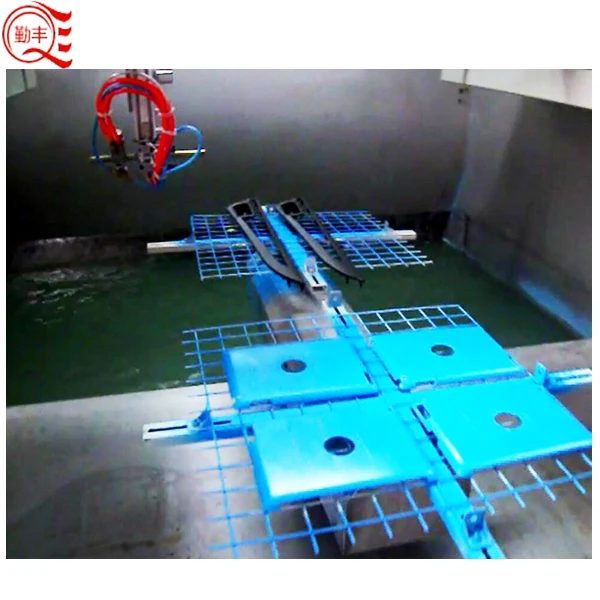

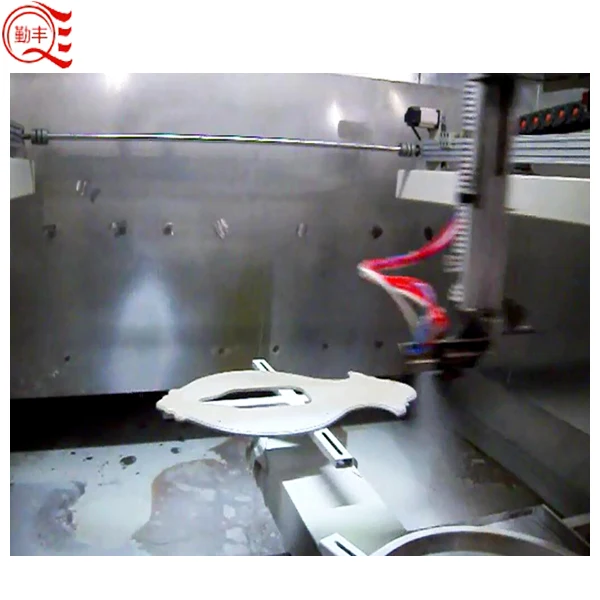

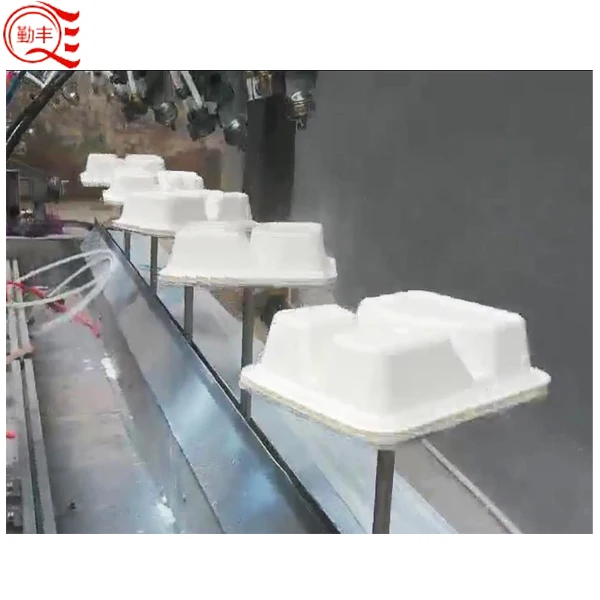

Product Pictures:

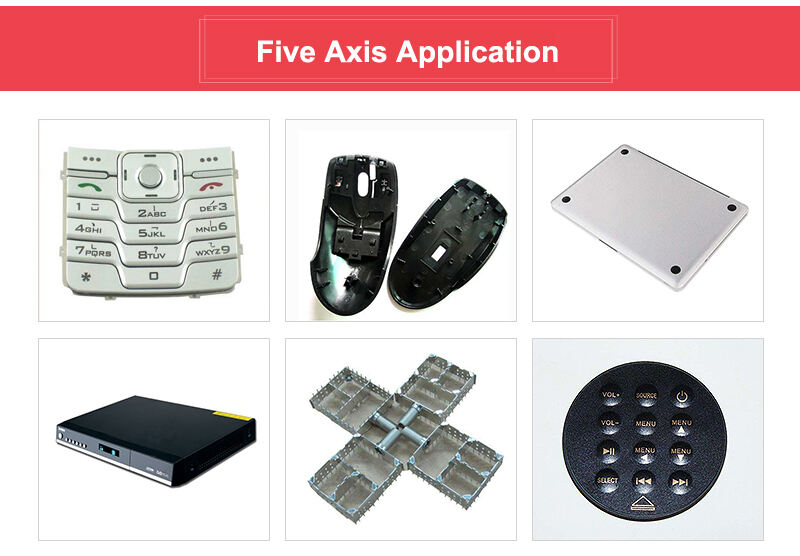

Application:

The five axis automatic spraying reciprocating machine is wildly used in the field of plastic, electronics, hardware handicraft, TV shell, computer panels, glass, toys, woodwork, magnet ring etc., also suit for large flat parts(such as door, glass) etc. precision surface spraying. The spraying process can reach the surface spraying or multi-surface spraying. Multi-axis linkage spraying or one axis reciprocating movement is OK. The parameter is adjustable flexible. The programming is convenient and fast.

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Our Service

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries. From a development department, Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment. After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ