Overview

Inquiry

Related Products

Online automatic spraying paint,simplify the middle stage from the human load-download workpiece

Fully enclosed spray pattern,reduce environmental pollution and man-made damage

Steady quality,spraying evenly

Automatic spraying,high efficiency, Save labor cost

Spraying degugging is simple within ten mins,The program is easy to operate

Factory Price,Competitive price

High quality,One year Warranty

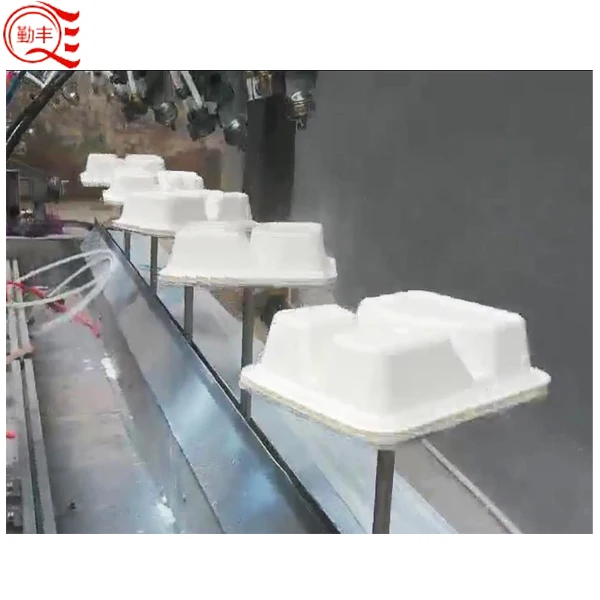

Whole factory plastic parts automatic dust coating equipment

Whole plant metal products electrostatic coating equipment

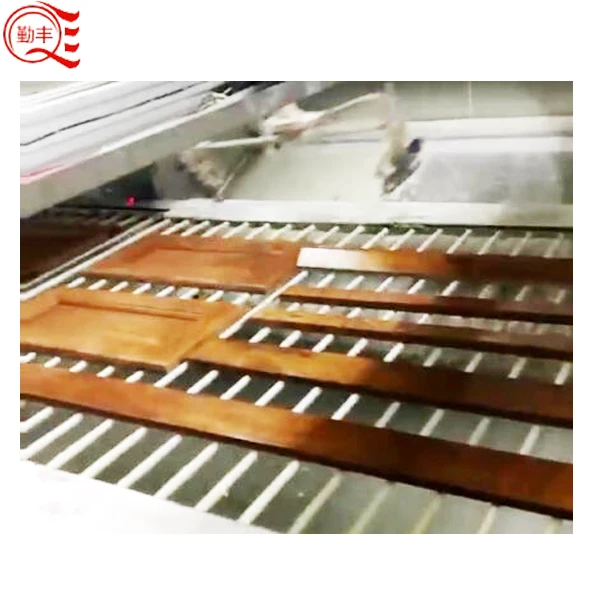

Whole factory furniture electrostatic coating equipment

Whole plant locomotive, motorcycle coating equipment

Manipulator, spraying robot etc. Industrial Robot equipment

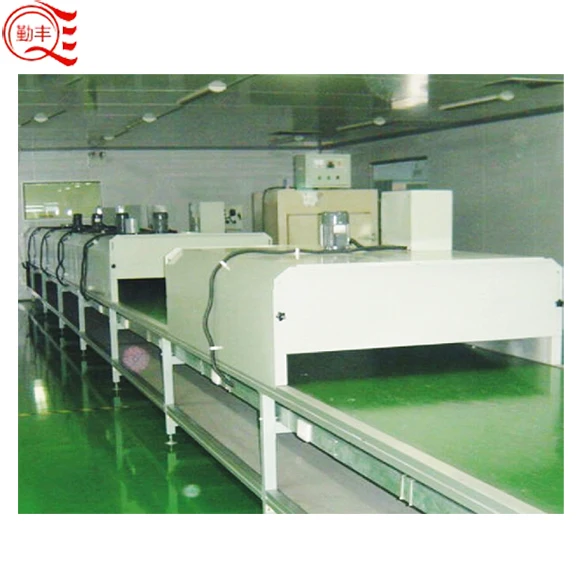

Automatic UV curing furnace line

Fully automatic electrostatic dust removal equipment

DISK automatic electrostatic coating equipment

All kinds of Drying, silk-screen equipment

All kinds of PVC/SUS belt, Nylon conveyor equipment

Teflon/Ceramic powder /PE immersion high temperature equipment

All kinds of Water Curtain Booth etc. equipment

High level Air Supply System

Waste water/waste gas recycling system

Whole plant electroplating coating equipment

Whole factory electrophoresis coating equipment

Xinqinfeng

Automated Spray Paint Production Line could be the solution is certainly perfect organizations that require a high level of effectiveness and quality within their finish processes. This production is innovative designed to automatically apply spray paint to many different areas, making it an ideal choice for companies such as for instance automotive, furniture, and construction.

Aided by the Xinqinfeng Automatic Spray Paint Production Line, you can bid farewell to the time-consuming, manual labor involved with old-fashioned artwork practices. This advanced system is fully automatic, permitting a manufacturing is streamlined that ultimately saves your business money and time.

Featuring components such as paint spray stands, spray guns, and paint drying systems, this manufacturing line is truly an answer that certainly comprehensive may be modified to satisfy your needs are particular. The paint spray booths supply an environment is controlled which to apply the paint, ensuring that each application is consistent and of good quality.

The spray weapons provide unparalleled accuracy, ensuring that the paint is evenly distributed throughout the surface being coated. And with the paint systems that are drying your products or services can be ready for the phase is next of in record time, letting you keep up with demand and stay in front of the competition.

The Xinqinfeng automated Spray Paint Production Line normally incredibly user-friendly as well as its impressive capabilities. This method was created to simplify your workflow while making your workday easier from its intuitive touchscreen interface to its automated cleaning rounds.

Also, the Xinqinfeng brand is well known due to the dedication to quality and innovation. With a past history is substantial of inside the coating industry, Xinqinfeng products are more popular because of the reliability and durability. You'll be able to be confident that you will be obtaining a top-of-the-line item that can help you achieve your manufacturing objectives for years in the future once you buy the Xinqinfeng Automatic Spray Paint Production Line.

Production Features:

Product Specification:

Item | Remark |

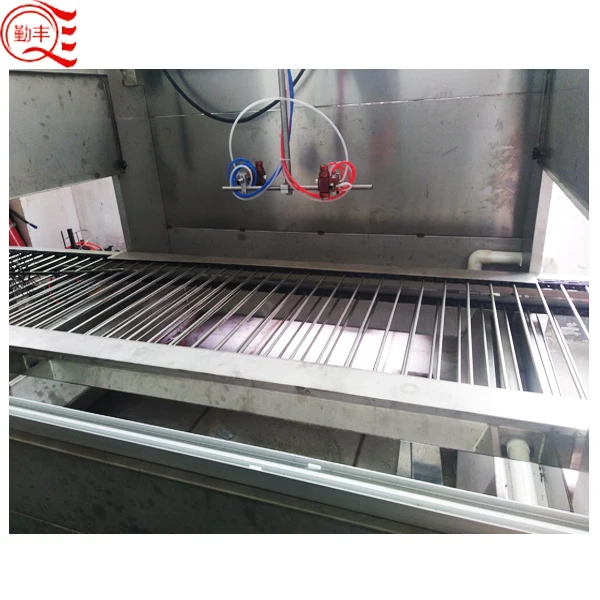

The conveyor line | 1. The foot of machine is equipped with the adjustable foot cup. 2. The transmission system use standard carbon steel with heavy load transmission roller. 3. The power system: The motor use Taiwan WANSIN brand 1HP gear reducer motor. 4. The transducer use The Taiwan DELTA brand 1HP frequency converter. 5.A set of transmission shaft, transmission parts are equipped with.(the speed range is within 0.1-6m/min) |

Water Curtain Spraying Booth

|

1. The bottom bracket is made of 50X50 stainless square box section and equipped with the adjustable M14 foot cup. 2. The tank is made by bending and welding 1.5mm 201# stainless steel sheets.

3. The pump adopts the Taiwan vertical pipeline pump. A set of PVC pipe and valve are also equipped. 4. The exhaust fan use a set of Taiwan Hong sheng 3HP centrifugal fan. (The air volume is 8000 cubic meters per hour).The ventilation duct is not included and provided by the customer. 5. The light use one 40W explosion-proof light with hood. 6. A set of electric control cabinet is equipped and the electrical accessories use the well-known brand. 7. The filtration system in the top of booth use the non-woven filter screen. |

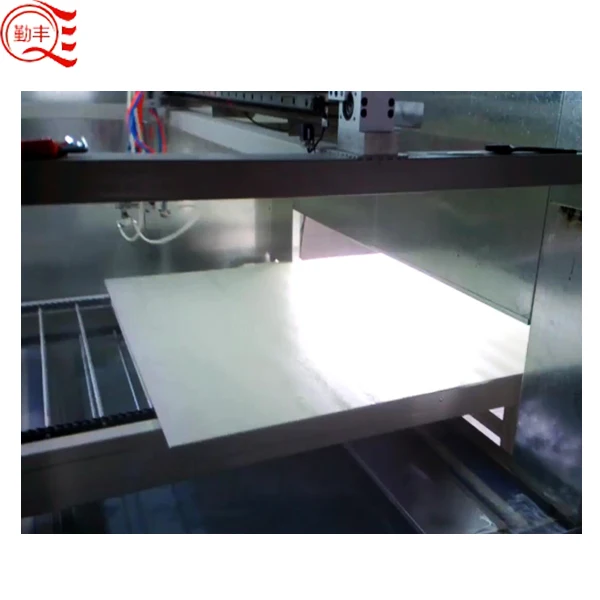

Single Axis Reciprocating engine ( 1 set)

| 1. the effective trip is within 1500mm.(can be customized) 2. The length of guide rail is 1500mm.The sliding rail use 25 series flange type self-lubricating linear guideway from Taiwan Hiwin brand with aluminum alloy module slider. 3. The sliding module adopt 65x65mm special aluminum for the reciprocating engine. 4. The PLC use Taiwan FATEK, The speed and trip can be adjustable. 5. The HMI use the Beijing MCGS 7 inch color touch screen. All adjustable parameters can be visualized and the button operation is simple. 6. The motor use the 400W low-inertia servo motor driving from Taiwan DELTA brand. 7. A set of electric control cabinet is equipped and the electrical accessories use the well-known brand. 8. 5M type synchronous wheel drive, the reciprocating synchronous belt adopts L special steel wire belt. 9. The speed is 1-3m/mins (can be customized). |

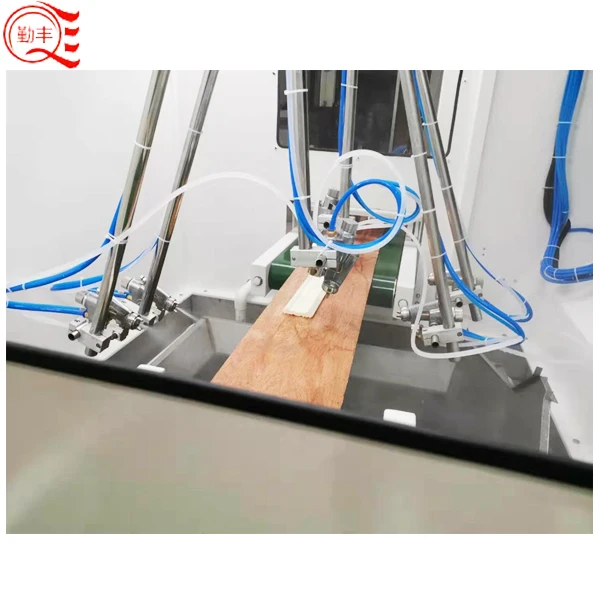

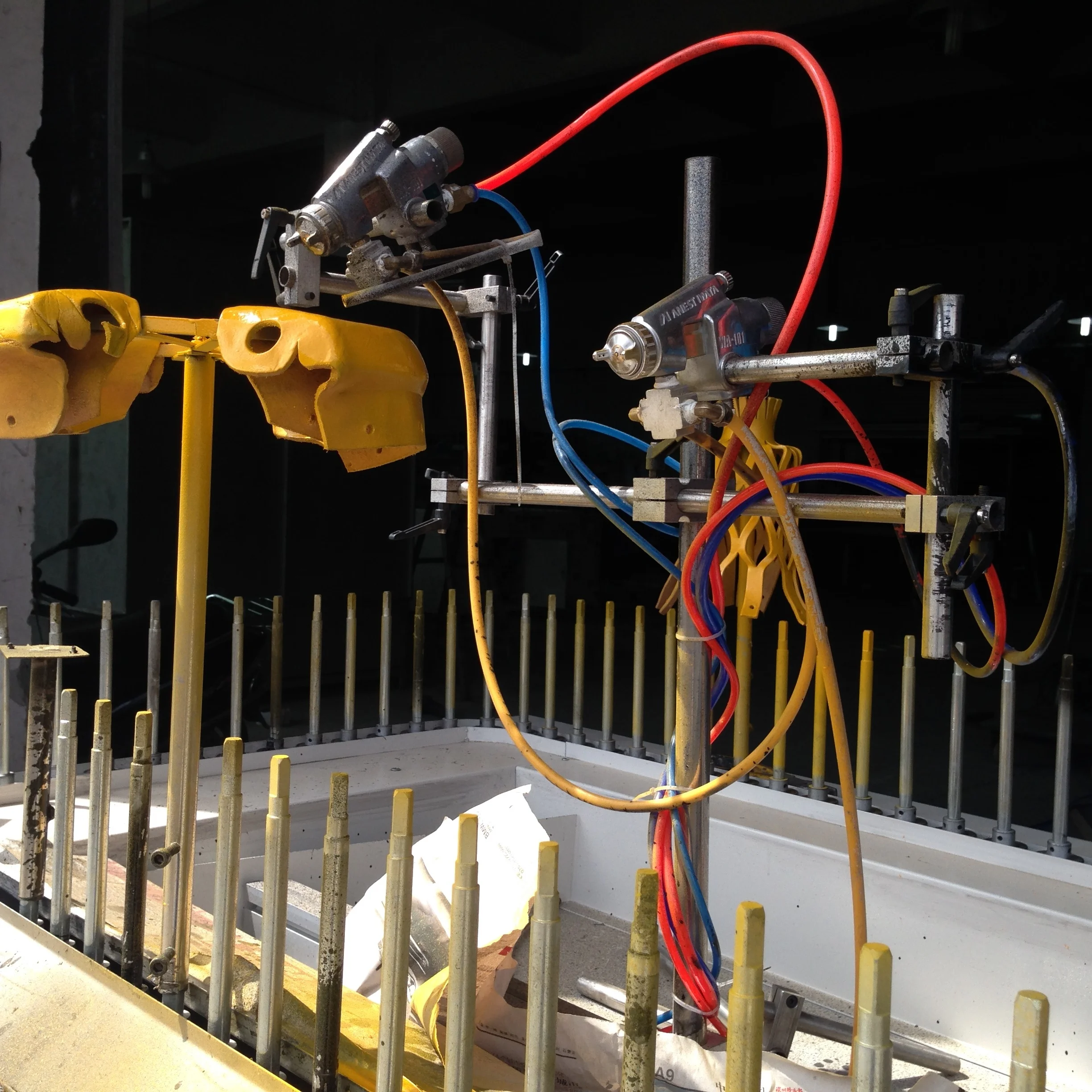

Automatic spray gun and oil supply ( 1 set) | 1. Automatic spraying guns: Japan ANEST IWATA brand WA-101 series automatic spraying. The Japan ANEST IWATA brand 101 series automatic spraying gun with the caliber is 1.0mm. The qty is 2pcs. 2. A set of Taiwan diaphragm pump is equipped. The caliber is trisection. 3. A set of Oil pipe, air pipe, oil-water separator, pressure regulating valve, electromagnetic valve are equipped. |

Electrostatic Precipitation

| The domestic electrostatic iron wind stick is installed in the feeding area. Firstly dust Off the product, Then enter the spraying room. |

Product Pictures:

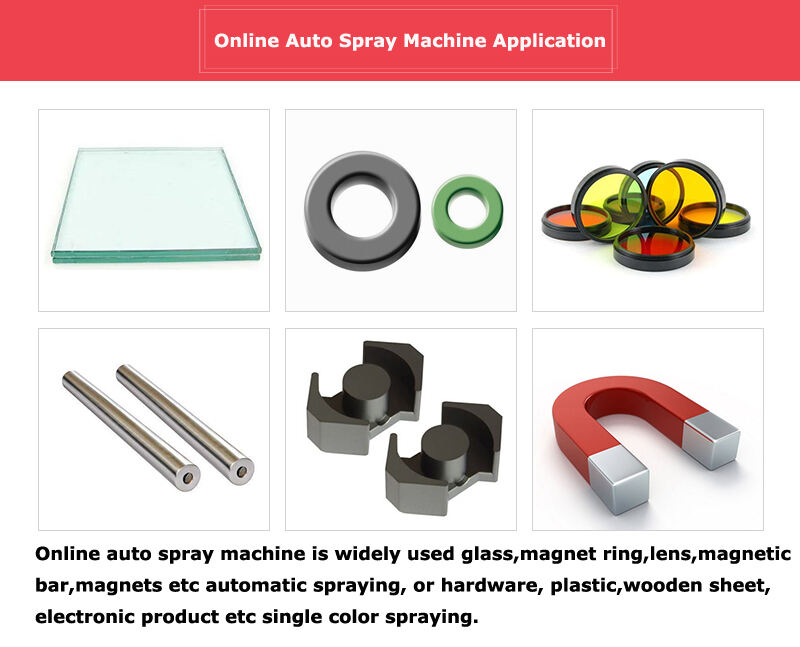

Application:

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries. From a development department, Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment. After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household appliances, medical equipment, metal products, construction machinery, mechanical and electrical products, motorcycles and other metal products, wooden furiture, plastic products and other types of products.

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ