Overview

Inquiry

Related Products

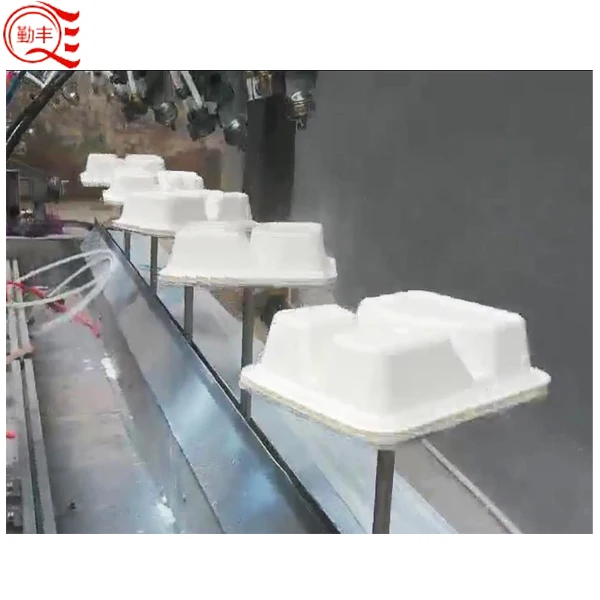

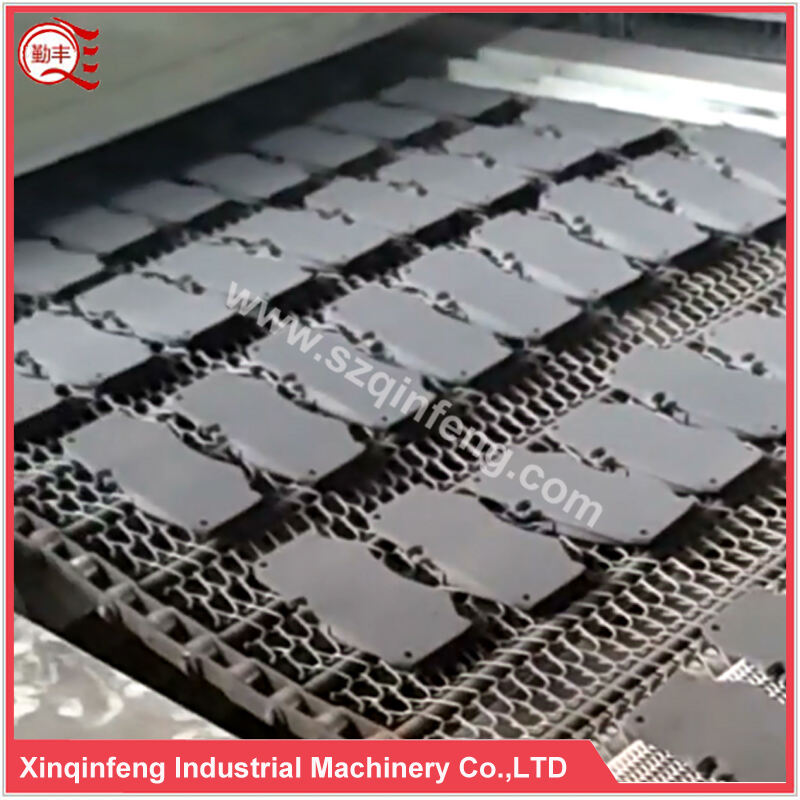

Online automatic powder coating line for brake pads,simplify the middle stage from the human load-download workpiece

Fully enclosed spray pattern,reduce environmental pollution and man-made damage

Steady quality,spraying evenly

Automatic spraying,high efficiency, Save labor cost

Spraying degugging is simple within ten mins,The program is easy to operate

Factory Price,Competitive price

High quality,One year Warranty

With the powder collector, Recycle devices,docking device

Whole factory plastic parts automatic dust coating equipment

Whole plant metal products electrostatic coating equipment

Whole factory furniture electrostatic coating equipment

Whole plant locomotive, motorcycle coating equipment

Manipulator, Spraying robot etc Industrial Robot equipment

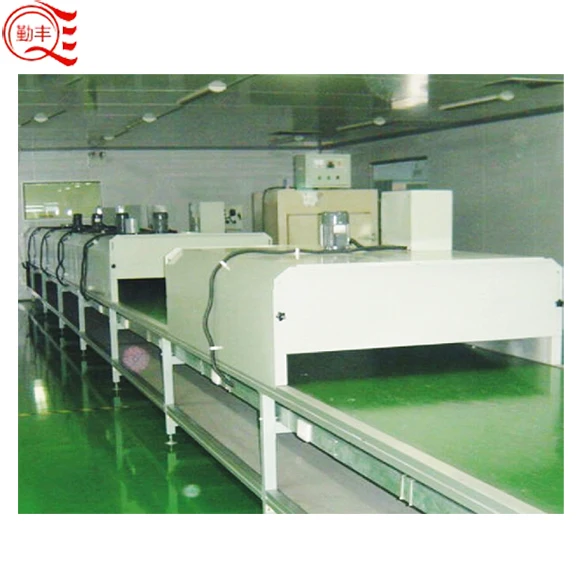

Automatic UV curing furnace line

Fully automatic electrostatic dust removal equipment

DISK automatic electrostatic coating equipment

All kinds of Drying,silk-screen equipment

All kinds of PVC/SUS belt,Nylon conveyor equipment

Teflon/Ceramic powder /PE immersion high temperature equipment

All kinds of Water Curtain Booth etc equipment

High level Air Supply System

Waste water/waste gas recycling system

Whole plant electroplating coating equipment

Whole factory electrophoresis coating equipment

The Brake Pads Powder Coating Line and Drying Furnace by Xinqinfeng is a item this is certainly top-quality is designed to effortlessly apply a durable and lasting layer of powder finish to brake pads. This product is perfect for people who want their brake pads to execute at their whilst that is best also searching great.

Using this particular powder finish line, users can expect a uniform and application this is certainly constant of finish, which can help to enhance the appearance of their brake pads while additionally increasing their performance. The powder finish is highly resistant to put on and corrosion, rendering it a range this is certainly excellent people who need their brake pads to be durable and sturdy.

The Xinqinfeng Powder Coating Line is not hard to make use of and certainly will be operated by anybody. Its developed to be both fast and efficient, permitting users to easily and quickly apply powder finish due to their braking system pads. This will make it a selection that is great organizations that need to produce big quantities of coated brake pads in a brief time frame.

But the finish process just is not where Xinqinfeng prevents. The drying furnace that comes with the line is equally as necessary to guarantee the powder layer remedies and forms a relationship this is certainly strong. Applying this furnace, users can guarantee that their brake pads has a high-quality powder finish which will endure for years later on.

The Xinqinfeng Brake Pads Powder Coating Line and Drying Furnace is made of top-notch materials, making sure it really is durable and sturdy. It is also an easy task to neat and keep, and as a consequence users can help to save money time coating their braking system pads significantly less time cleaning after on their own.

Production Features:

Product Specification:

Item | Remark |

The conveyor line | 1. The conveyor line size: L3000 X W800 X H1050mm, the racks use detachable design. 2. The foot stool is made of welding 50x50mm stainless steel box section. The foot of machine is equipped with the adjustable foot cup within 30mm. 3. Adopt PVC Danish green conveyor belt, the total length of the belt is 6 meters 4. The body is made of 2.5mm welding stainless steel box section. 4. The power system: The motor use taiwan WANSHSIN brand 1HP gear reducer motor.The transducer use The taiwan DELTA brand 1HP frequency converter. A set of transmission shaft, transmission parts are equipped with.(the speed range is within 0.5-2m/min) 5.1 set of automatic powder cleaning device |

Spraying Booth

| 1. The Paint booth size is W1400mm×D2290mm×H3000mm 2. Operation method: automatic spraying. 3. Operating wind speed: the average wind speed at the opening after spraying is 0.4m/s. 4. Powder recovery method: the filter element is directly recovered, with an automatic pulse backwash system. 5. Specifications: The shape is W1800mm×H2500mm×D1900mm. 6. Main body material: 1.2mm202 stainless steel plate is used for the side plate, and 1.2mm202 stainless steel plate veneer is used for the bottom plate. 6. Lighting: 1 set of dust-proof fluorescent lamp 30W. 7. Fan model: medium-pressure high-speed centrifugal fan, air volume and pressure: 2000m3/h, static pressure 1500pa, motor: 3KW, 380V. 8. Filter tube: The material is pleated fiber non-woven fabric, the smallest filter size is Φ325*L600. 9. Control electrical appliances: timers, relays, relay switches and indicator lights all adopt the Chint series. 10. Pulse control: electronic digital display time relay, pulse width 1-60s, pulse interval 1-60, minute optional. 11. Backflush: Pulse nozzles, equipped with 4 pcs. 12. Gas storage tank: 1 Φ120×600. 13. 1 set of automatic recycling and sieving mechanism |

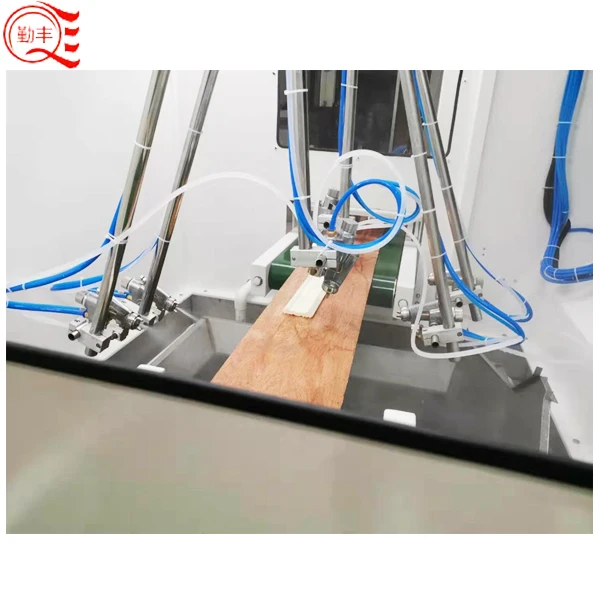

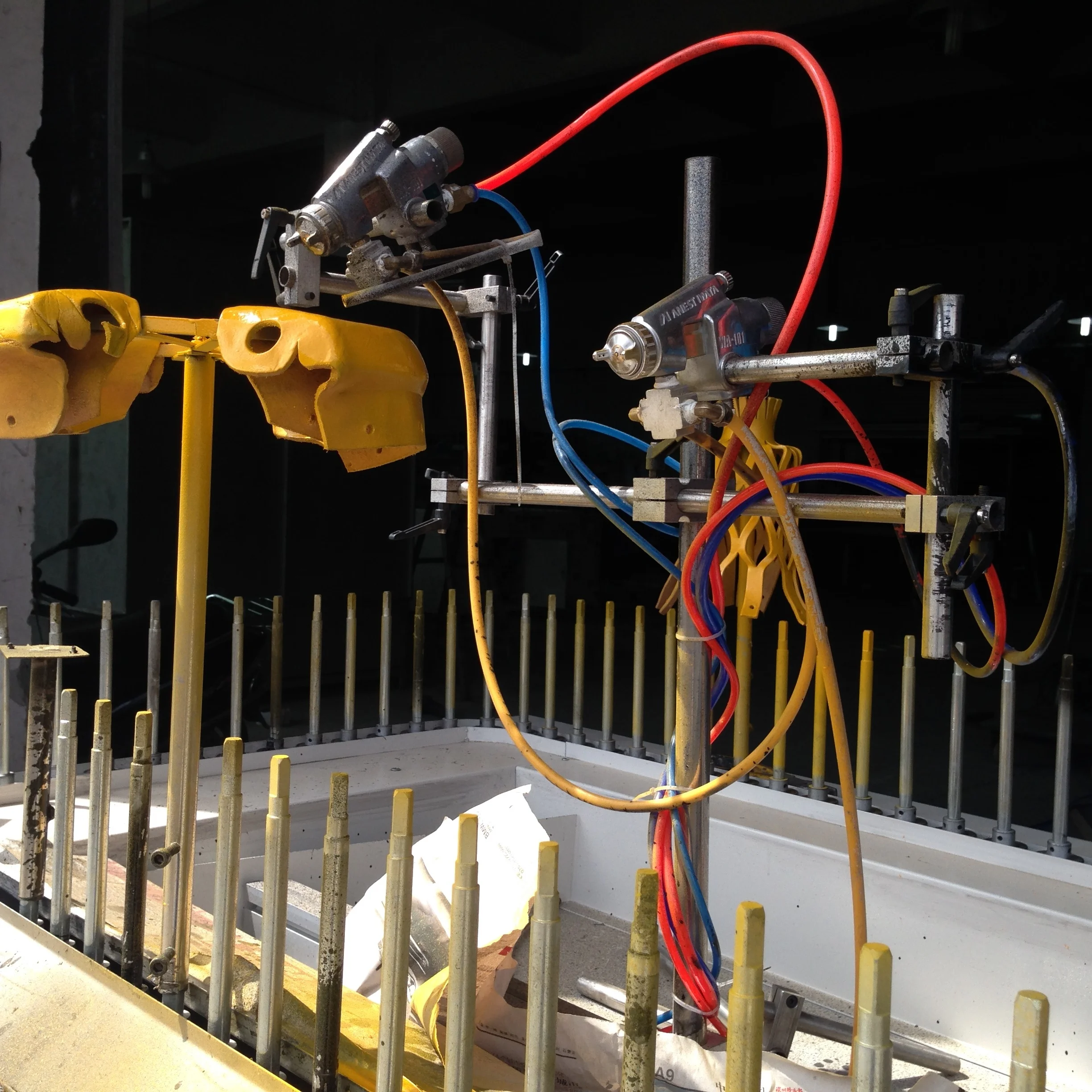

Single Axis Reciprocating engine ( 1 set)

| 1.The Effective spraying width: 800MM. 2. It adopts 65*65 special aluminum material for reciprocating machine, 400W Delta servo motor, and special timing belt. 3. PLC adopts Taiwan FATEK brand with adjustable speed. The stroke is adjustable. 4. The touch screen adopts 7-inch MCGS communication mode. All adjustable parameters can be directly reflected. Brief section of key operation. 5. 5M type synchronous wheel drive. The reciprocating synchronous belt adopts L special steel wire belt type. 6. Taiwan HIWIN 25 series flange-type self-lubricating linear track, equipped with aluminum alloy module slider, linear slide bearing, single slide reciprocating transfer, McGaudi timing belt. 7. The speed is 0-1.5 meters per second. 8. The opening of the spray gun can be realized on the touch screen, electric box panel, photoelectric switch, etc. 9. 2 pcs domestic automatic powderElectrostatic spray guns |

Product Pictures:

Application:

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household

appliances, medical equipment, metal products, construction machinery, mechanical and

electrical products, motorcycles and other metal products, wooden furiture, plastic products

and other types of products.

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ