Overview

Inquiry

Related Products

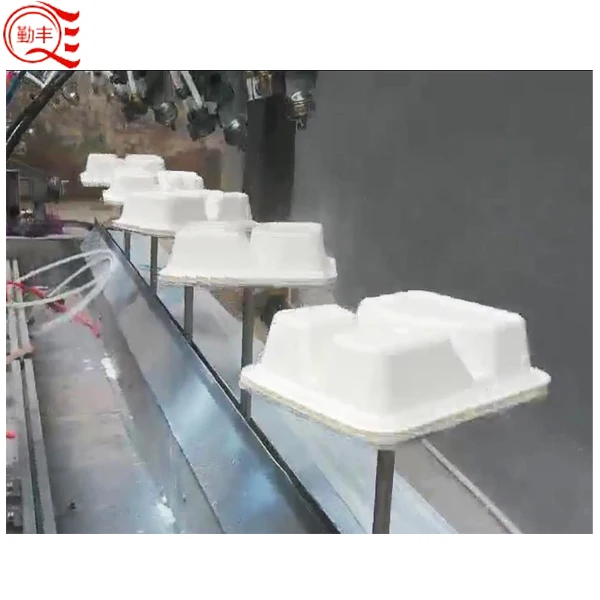

Whole factory plastic parts automatic dust coating equipment

Whole plant metal products electrostatic coating equipment

Whole factory furniture electrostatic coating equipment

Whole plant locomotive, motorcycle coating equipment

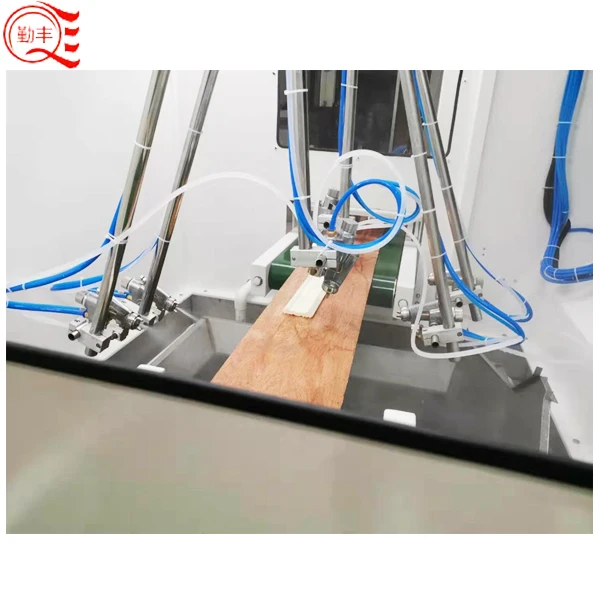

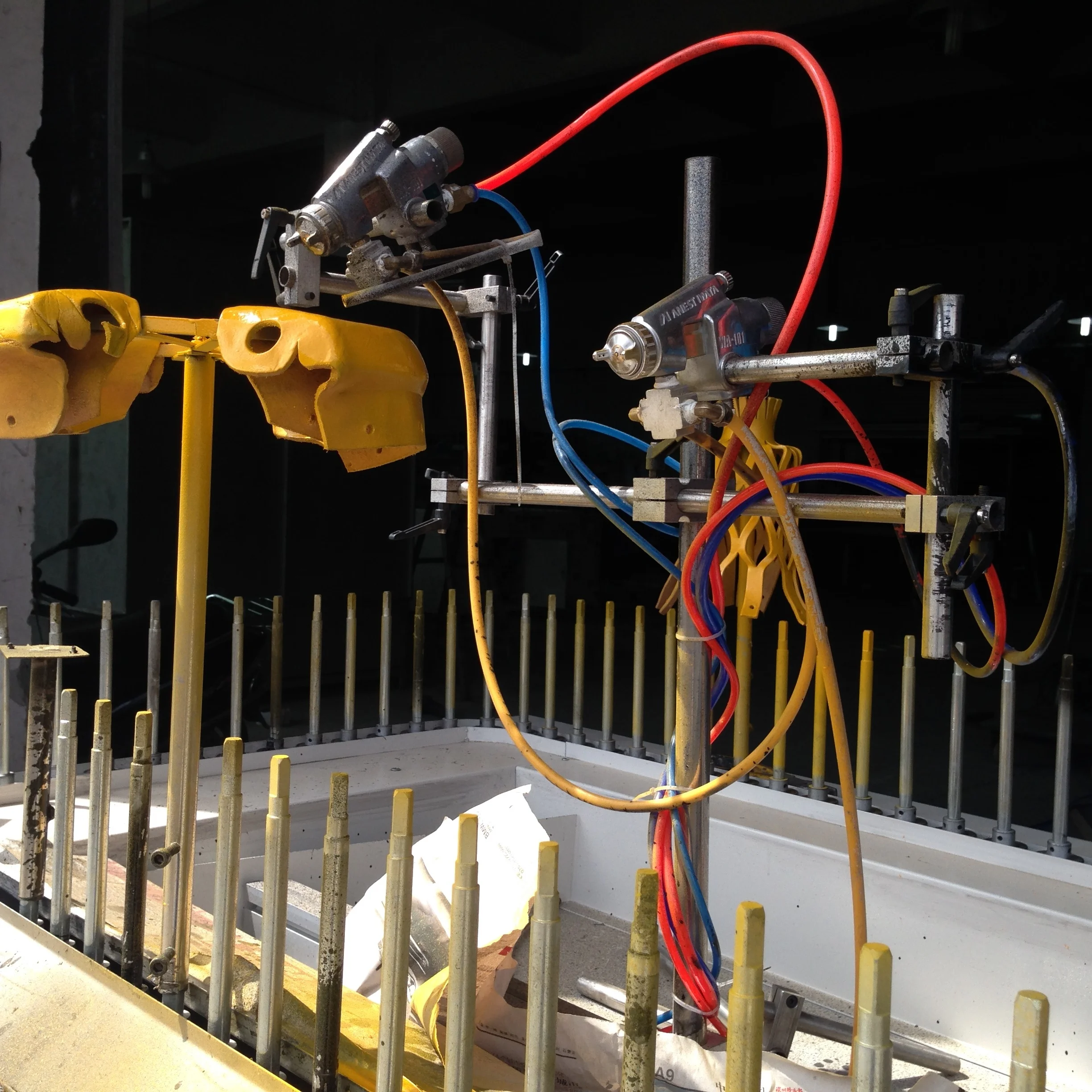

Manipulator, Spraying robot etc Industrial Robot equipment

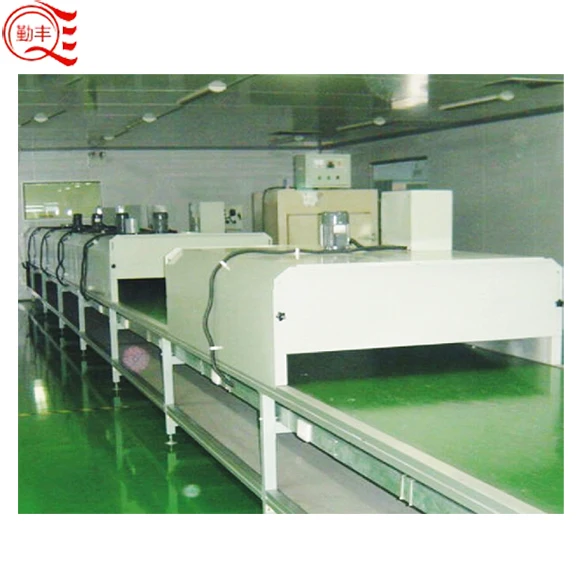

Automatic UV curing furnace line

Fully automatic electrostatic dust removal equipment

DISK automatic electrostatic coating equipment

All kinds of Drying,silk-screen equipment

All kinds of PVC/SUS belt,Nylon conveyor equipment

Teflon/Ceramic powder /PE immersion high temperature equipment

All kinds of Water Curtain Booth etc equipment

High level Air Supply System

Waste water/waste gas recycling system

Whole plant electroplating coating equipment

Whole factory electrophoresis coating equipment

Presenting the Xinqinfeng Six-Axis Spraying Robot for Spray Paint manufacturing, the answer that is clear perfect for optimizing your manufacturing process. This advanced level robot that is commercial meant to streamline the spray artwork process and enhance item quality and effectiveness.

This Six-Axis Spraying Robot uses technology that will certainly deliver that is cutting-edge and constant outcomes. This robot can accurately target spray paint onto perhaps the many complex areas with six axes of movement and advanced sensors. Also, this robot has been the capability of spraying with both airless and spray that is old-fashioned, and that can handle many different materials and coatings.

One benefit this is certainly major of robot is its capacity to work autonomously. As a result of its computer software this is certainly advanced and capabilities, it could easily be programmed to do specific tasks and run seamlessly along with other equipment in your manufacturing line. This frees up manpower and decreases mistakes due to peoples oversight.

Additionally, this robot is incorporated with advanced level safety features to guarantee the security of one's workers and equipment. Designed with heavy-duty aluminum structure and sensors that are advanced it could easily navigate through obstructions and address safety issues such as for example spraying in a environment this is certainly possibly hazardous.

The Xinqinfeng Six-Axis Spraying Robot is engineered to be lasting and sturdy. It utilizes elements that can easily be high-quality materials, making sure it remains dependable and low-maintenance for many years to come. This results in greater cost and productivity benefits to the run this is certainly very long.

Production Features:

1. The painting is precise, the normal run time is long, the paint consumption is less. It runs 24 hours and has higher reliability.

2. The painting speed is quick and even. The user can automatically adjust the painting height, direction, angle position based on parts. The painting control is flexible. Omnidirectional painting can be achieved.

3. It is anti-explosion, and environment friendly. It has higher safety, and the operation control

is easier to learn.

4. Spraying painting robot can paint 2 or 5 kinds of product simultaneously.

5. Spraying painting robot has long service life and easier maintenance.

Kawasaki Robot Parameter List

No. | Items | Specification | |

1 | Brand | Kawasaki spraying robot | |

2 | Body Parameter | maximum load bearing | 5KG |

Degree of Freedom | 6 Axis (JT1,JT2,JT3,JT4,JT5,JT6) | ||

Maximum Radium of Activity | 1000MM | ||

Installation Type | Install the seat to be mounted upside down | ||

Driver Type | Kawasaki AC servo drive | ||

IP Degree | Intrinsically safe and pressurized Level 1, Zone 1, Group IIB and T4 certification | ||

Repeated Positioning Accuracy | ±0.2MM | ||

Product Pictures:

The Main Features of Spraying Robot:

1.Increasing the production efficiency,Widely useing in various fields

2.High spraying efficiency, Best finishing quality;

3.Automatizing the paint process;

4.Less maintenance requipent and long time span

5.Labor cost is reduced

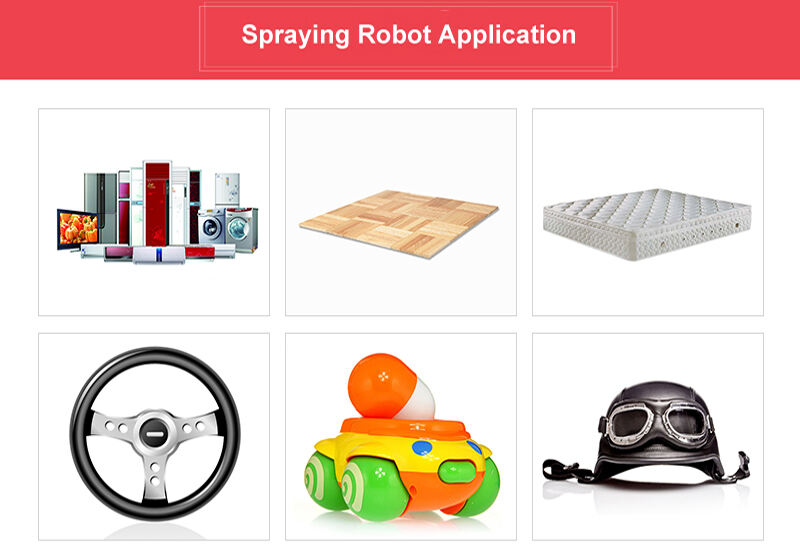

Application:

The five axis automatic spraying reciprocating machine is wildly used in the field of plastic, electronics,hardware handicraft, TV shell,computer panels,kitchen ware,Car and Car parts,bathroom ware,Power industry etc many fields.

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

4.Q: What is price of the machine?

Answer: Normally, Most of the machine is customized for our customer. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please send us the detail infos about your workpiece as blow:

1. The maximum size of workpiece:

2. The max weight of workpiece:

3. The output per month/per day:

4. Heating Temperature and Time(If you need the drying equipment):

5. Color changing(How many colors? How long will it take to change other colors ?)

6. Spraying process(What paint will you use? Spraying times? )

7. The workshop size for the equipment:

8. Some work-piece pics are needed:

9. The power: industrial three phase voltage

10. Other requirements from customer:

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household

appliances, medical equipment, metal products, construction machinery, mechanical and

electrical products, motorcycles and other metal products, wooden furiture, plastic products

and other types of products.

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

If you can send us some pics about your product with capacity per day and size for first reference. Once get your infos, We will send you our solution with price ASAP.Appreciating for your support,

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ