Overview

Inquiry

Related Products

Brand: Xinqinfeng

The Hanger Electrostatic velvet this is certainly flocking by Xinqinfeng is a cutting-edge item that delivers a dependable and solution that is efficient several your flocking needs. This machine is equipped to keep out your complete flocking needs whether maybe you are looking after a production this is certainly large or have to finish a DIY that is little task.

The unit produces an electrical cost that is driven attracts the flocking materials to your surface for this product featuring its impressive technology this is certainly electrostatic. This suggests that the fibers stick firmly to your material, having a soft and velvety texture this is certainly both long-lasting and sturdy.

Making utilization of this product is straightforward and easy, with easy settings that permit anyone to adjust the cost, voltage, as well as other settings based on your needs. You might select from many flocking this is certainly different that you can get in several colors and textures, giving you control that is complete the design this is certainly best of one's flocking task.

The Hanger Electrostatic velvet that is flocking is designed with efficiency and efficiency in your head, laden up with an engine this is certainly strong ensures quick and flocking that is precise. Its design this could additionally be undoubtedly ergonomic user comfort and decreases the opportunity of fatigue during long work hours.

This item this is certainly ideal that is revolutionary a number of applications, from fashion and textiles to commercial and sectors which are automotive. Its flexibility and reliability allow it to be perfect for both tiny and projects which are large-scale are flocking making certain it is possible to realize outcomes which is often time that is expert.

The Xinqinfeng brand is well understood because of the quality products and consumer this could exemplary be certainly, plus the Hanger Electrostatic velvet this is certainly flocking is not any exclusion. The product that is revolutionary intended to final, with durable components and construction that is robust can withstand many years of great usage.

| Production Features: |

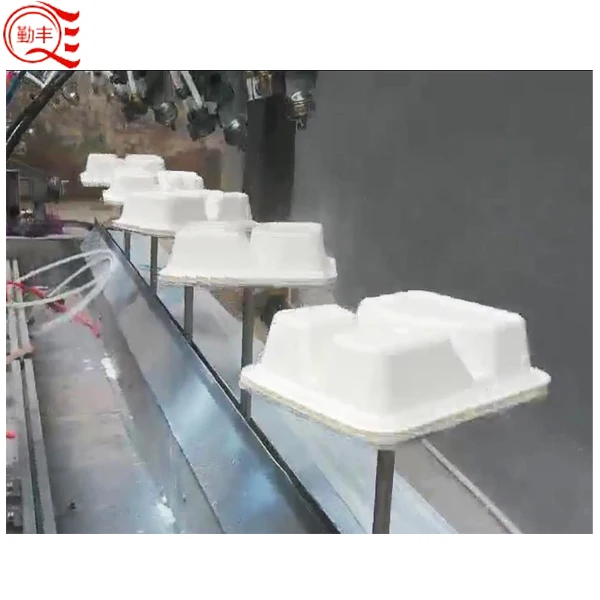

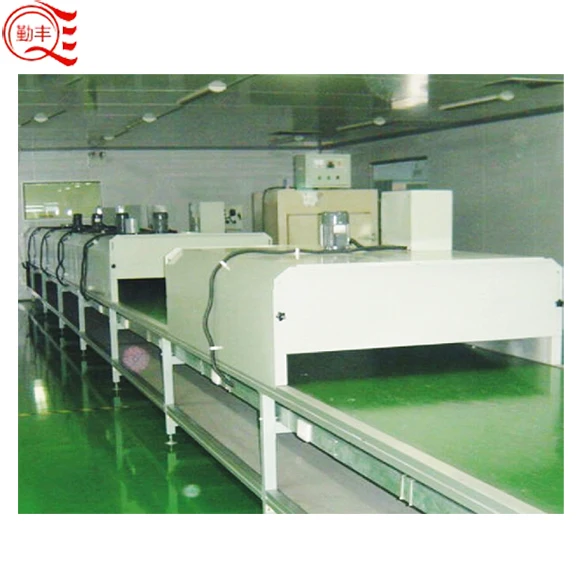

fully automatic Glass bottle(Other product also can be designed) flocking production line

Main features and advantage of automatic glass bottle production line

1.The sealing design of flocking cabinet can ensure the working environment is clean and dust-free. eco-friendly and keep health to operating workers.

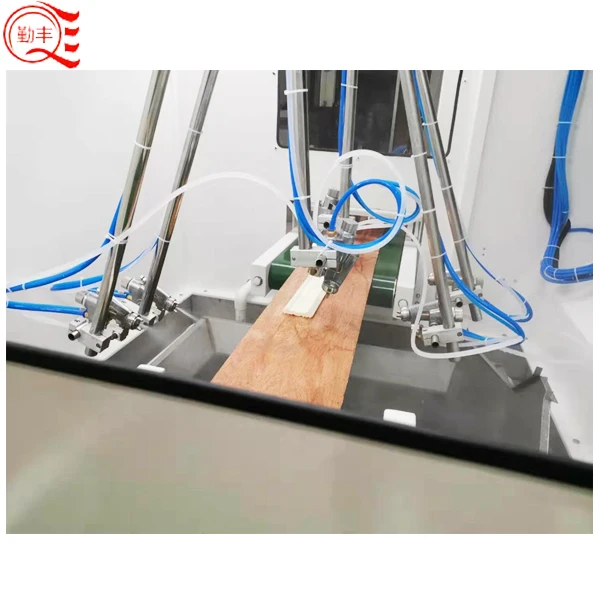

2.Automatic flocking machine with automatic gluing system, daily output can up to 3000-4000 pcs per day, saving your labor cost and time.

3.designed for flocking on different glass bottle,perfume bottle,Wine bottle,Comestic bottle,cup etc.

4. User friendly design, convenient operation.

Features of electrostatic flocking

Electrostatic flocking is a surface decoration method in which the fiber fluff is polarized by an electrostatic field, and the polarized fluff is neatly erected on the surface of the glued substrate along the power line, and fixed on the surface of the substrate after drying. The surface of the wood-based panel substrate can be beautified by electrostatic flocking, the defects on the surface of the substrate can be covered, and the variety of colors on the surface of the wood-based panel can be increased. Flocking products have a style similar to embroidery, suitable for advanced interior decoration, such as wall, ceiling, countertop, etc., can be used for furniture decoration, protect the surface of high-end products such as instruments, meters, musical instruments, etc., and can also be made into arts and crafts, such as Three-dimensional surfaces such as calligraphy, paintings, and patterns.

According to the different flocking products, choose the appropriate flocking method, generally divided into three types:

1. Flocking machine line-type flocking: The flocking line can realize the automatic completion of gluing, flocking, drying, and flocking removal of items at one time, such as: flocking cloth, leather, paper, non-woven fabric , PVC, blister sheets, sponges, various handicrafts, toys, automotive plastic parts, storage boxes, automotive sealing strips, decorative strips, blister boxes, cardboard, calendars, couplets, New Year pictures, flocking of packaging gift boxes printing.

2. Box-type flocking: According to the size and shape of the flocked product, a flocking box is made, the fluff is placed in the box, and the power is turned on, so that a high-voltage electric field is formed in the flocking box, and the flocked product is flocked from the flocking box. One end of the box is sent into the box, and after three to five seconds, the flocking is completed and then removed from the other end of the box, and the finished product is dried or dried.

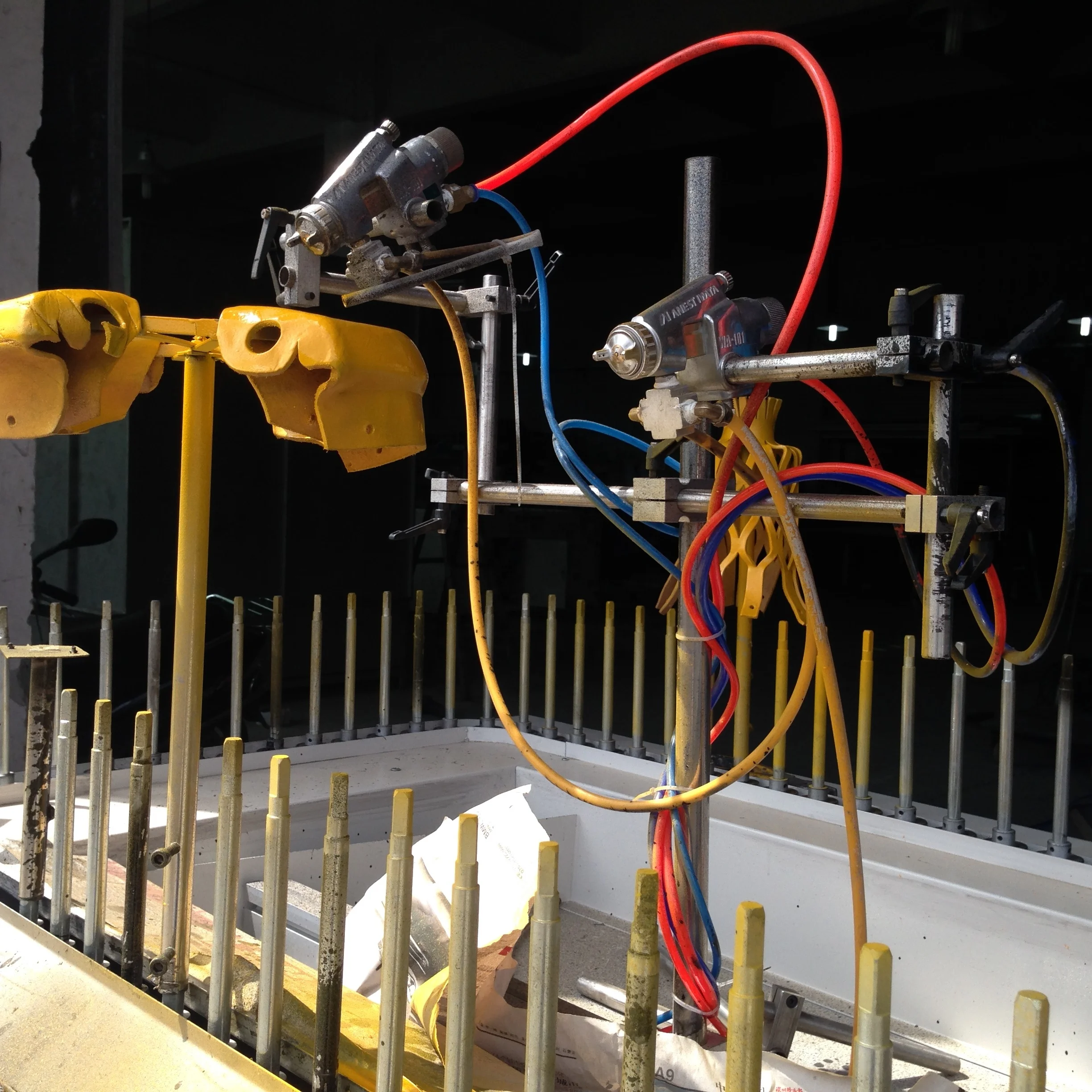

3. Nozzle flocking: connect the power supply, and output tens of thousands of volts of high-voltage static electricity generated by the flocking machine to the industrial nozzle. The fluff in the nozzle is negatively charged, and then the surface of the plant body is sprayed with adhesive. The nozzle is close to the flocked object, and the fluffs fly from the nozzle to the surface of the flocked object under the action of a high-voltage electric field, and are vertically planted on the surface of the object coated with the adhesive.

| Product Pictures: |

| Application: |

The field of flocking industry is very broad, and the representative industries are:

1. Handicraft industry: toys, handicrafts, photo frame backboards, gifts, craft calligraphy and painting, artificial flowers, craft plastic lanterns, etc. of various styles and materials.

2. Packaging industry: jewelry boxes, health product packaging boxes, wine boxes, glasses boxes, marriage certificates, high-end certificate skins, wine bottles, luggage, stickers, cardboard (board), etc.

3. Automotive industry: automotive rubber seals, automotive interior plastic parts, etc.

4. Other industries: motorcycle helmets, hangers, fire doors, safes, lamps, cabinets, sanitary ware, furniture, sponges, EVA, hangers of various materials, etc.

5. Resin, ceramics, gypsum, glass, plastic, recycled plastic handicrafts, flocking on the surface of toys

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ