Overview

Inquiry

Related Products

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

- Manipulator, Spraying robot etc Industrial Robot equipment

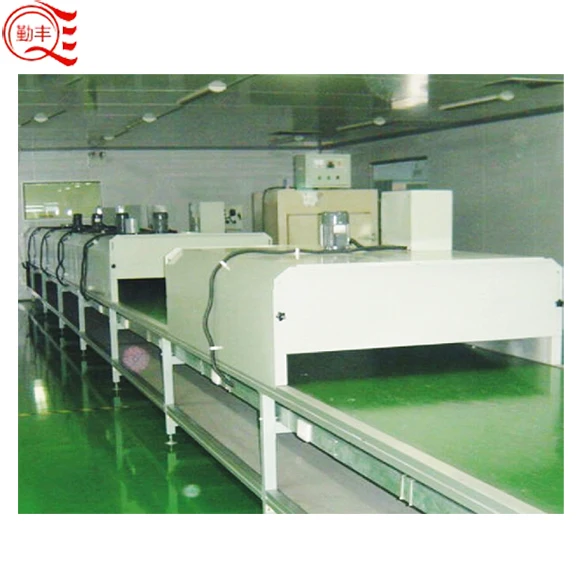

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

Industrial drying furnace for plastic painting and drying techique

A. Instant drying; avoid drying waiting time, greatly reducing the coating process time.

B. It can be directly connected with the coating machine. The machine can be connected to the drum type or curtain coating machine. After coating, the finished product is directly dried, eliminating the trouble of handling.

C. Coating surface hardness increased, bright color.

D. Extensive drying function: wood, plywood, furniture, steel, building materials, lenses, leather and other UV coating after drying.

Product Specification:

|

No. |

Item |

Specification |

|

A |

The size |

Size:L2500 × W690(Effective width) x H800mm(Qty:1pcs ) |

|

1 |

The racks |

The body,foot of equipment is made of welding steel box section. The foot stool is equipped with M14 adjustable foot cup. the steering wheel is equipped. |

|

2 |

The Conveyor Belt |

The belt height to the ground is 0.8 meters. The width of steel mesh belt is 690mm, the circle length is 5 meters. The length of feeding area is 500mm,the effective height is 250mm, which is adjustable. |

|

3 |

Motor |

The motor use 60W electronic speed regulating motor. the line speed is adjusted Taiwan ZONCN frequency transformer. 1-6m/min, Energy-saving power. |

|

4 |

Surface treatment |

Computer white electrostatic powder coating,hard wear and scratch resistant |

|

B |

Drying furnace cover |

The heating area size is L1200mm×W700mm×H550mm. |

|

1 |

UV Lamp |

It uses 3pcs 3KW UV lamps with transformer and capacitance. Each lamps has three choose: strong,medium,week. The lamps use the Beijing halogen tube with the reflector,tube,trigger. |

|

2 |

The Wind Motor |

It use one set of professional 1.1KW 380V,1400R/min high speed centrifugal fans. The volume of air is 1200m3/hours. 1 set. The inner is equipped with the exhaust pipe which can reduce the temperature of product and the inner of furnace,improve the service time of the lamp. |

|

3 |

Electronic Controller |

The transformer of UV lamps is equipped with the energy storage capacitance. Each UV lamp is equipped with a time timer to record the usage.The temperature-controller uses the Taiwan Berme digital display temperature controller. |

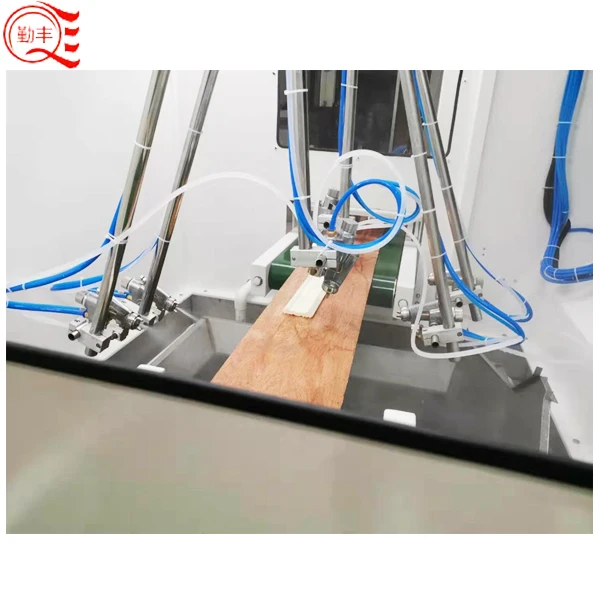

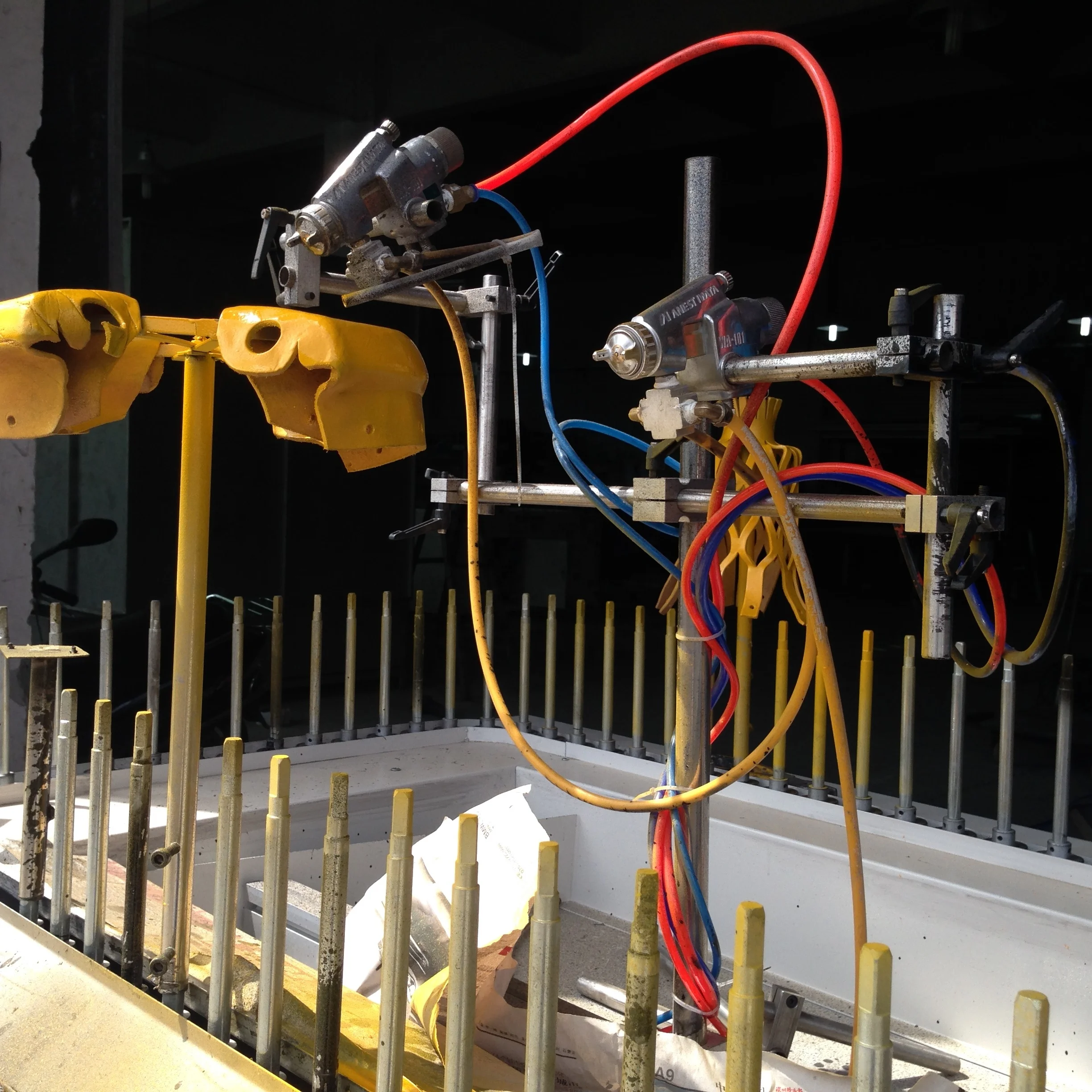

Product Pictures:

Application:

UV curing has been widely adopted in many industries including automotive, telecommunications, electronics, graphic arts, converting and metal, glass and plastic decorating.

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Company Pictures

Other Hot Selling Equipment :

Packageing & Shipping:

1.The equipments will be wraped with plastic film, and then in container

2.We can also customize wooden case to pack the equipments is customers need.

Our Service

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

FAQ

Question 1: I don't know anything about the machine. Will you provide the technical support?

Answer: Sure. Every machine will be test before delivery. We will make sure there is no problem for the machine while it leave our factory.

When the equipment is small and standard ,We can send the detailed user manual and video to help you install and operate the equipment. Of course,You can arrange 2-3 smart workers to come to our factory to learn how to operate the machine.

If the machine is very big and long,When the machine arrives your factory, we will send the experts to your factory to help for installation and commissioning. Operation training will be provide. Maintenance tips will be given and enough spare parts be provided.

Also, we provide consulting service for creating the proper facilities for running the machine.

Question 2: What is UV Curing? ?

Answer:Ultraviolet curing (commonly known as UV curing) is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or “dry” inks, coatings or adhesives. Offering many advantages over traditional drying methods, UV curing has been shown to increase production speed, reduce reject rates, improve scratch and solvent resistance, and facilitate superior bonding.

Appreciating for your support, if you can send us some pics for reference. Once get your infos, We will send

you our solution with price ASAP.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ