Overview

Inquiry

Related Products

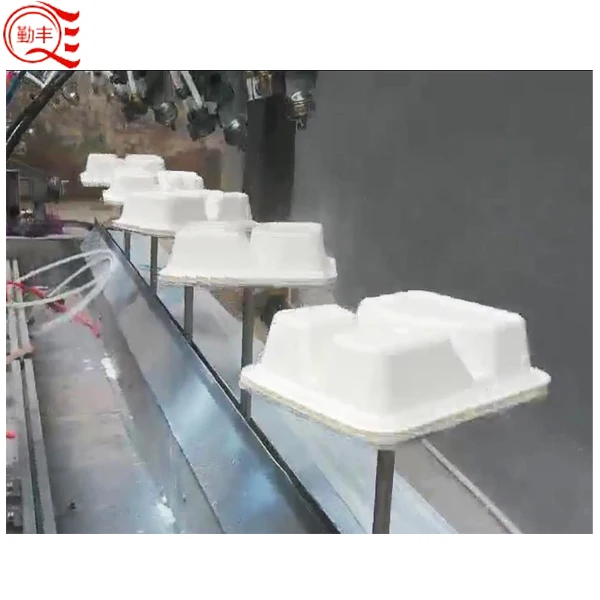

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

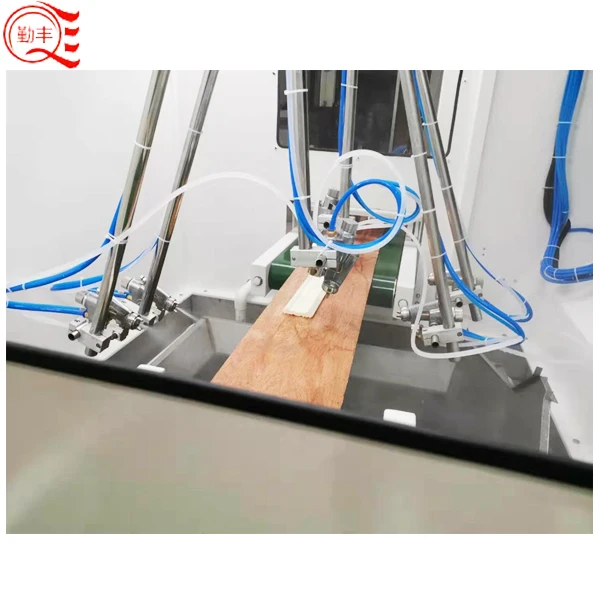

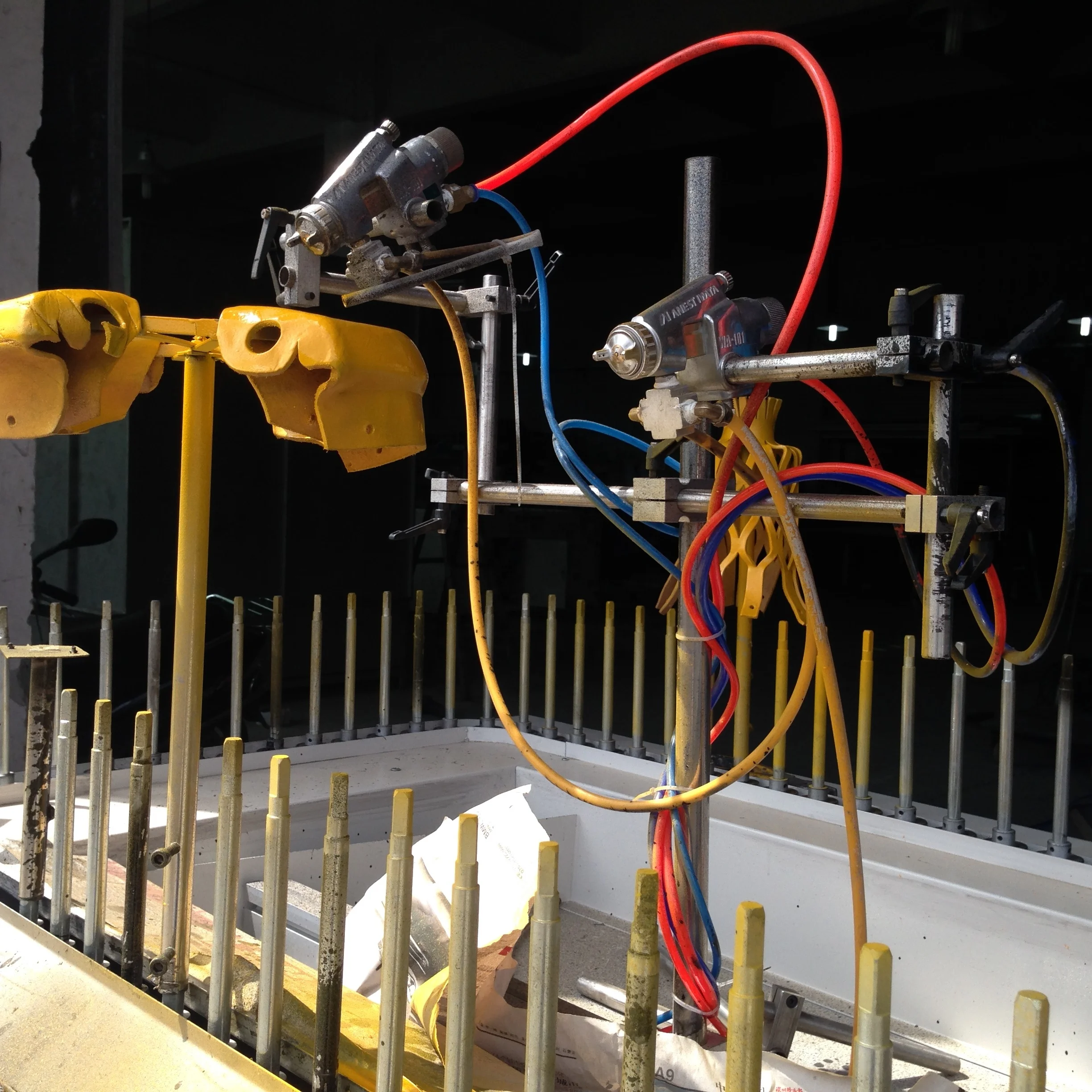

- Manipulator, Spraying robot etc Industrial Robot equipment

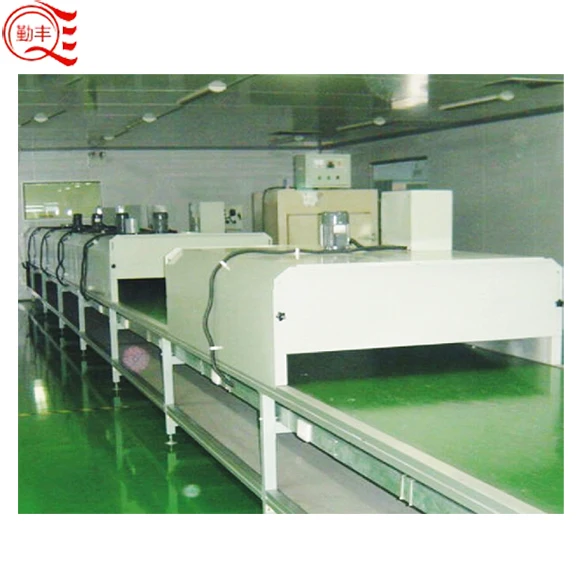

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

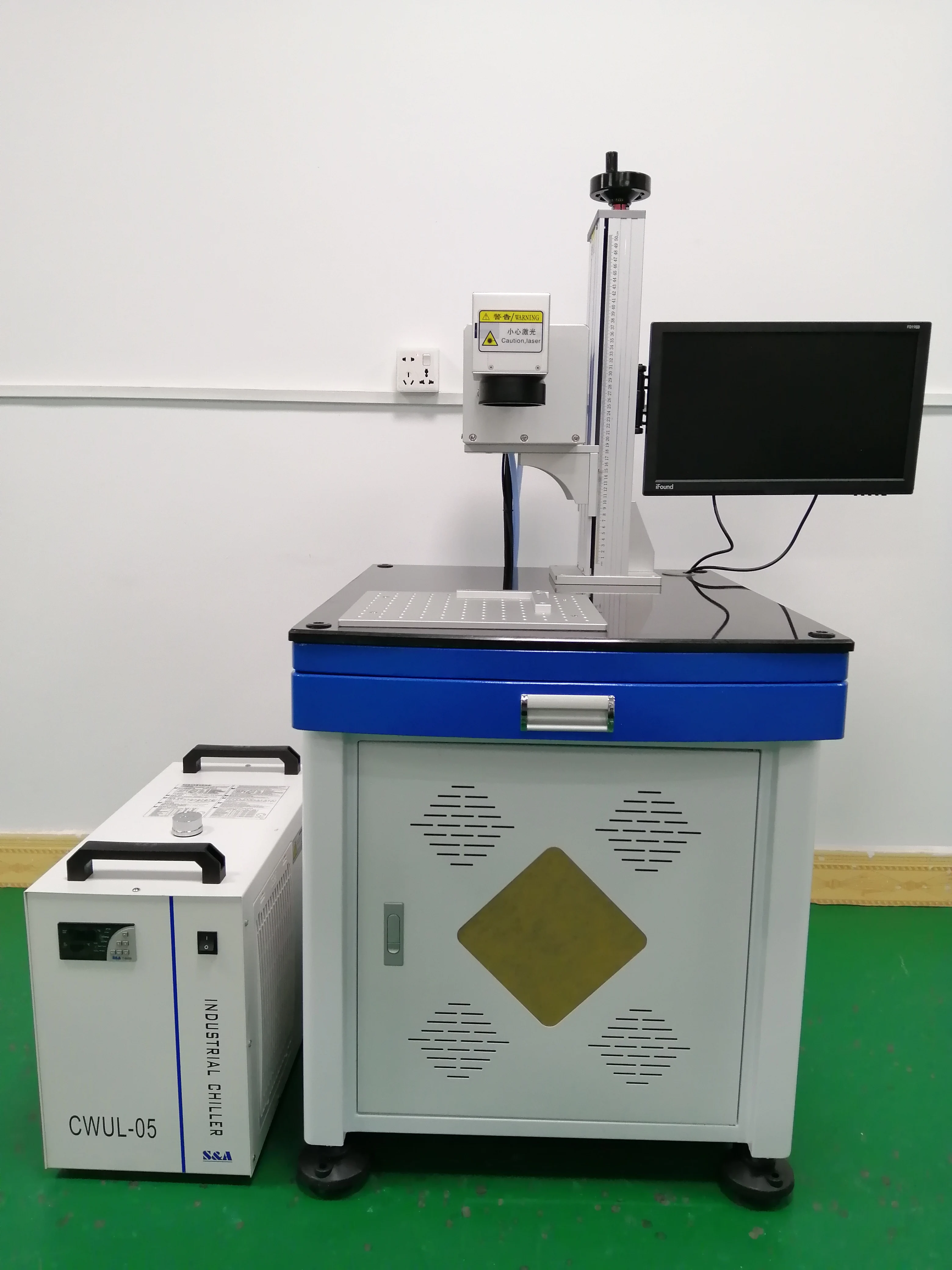

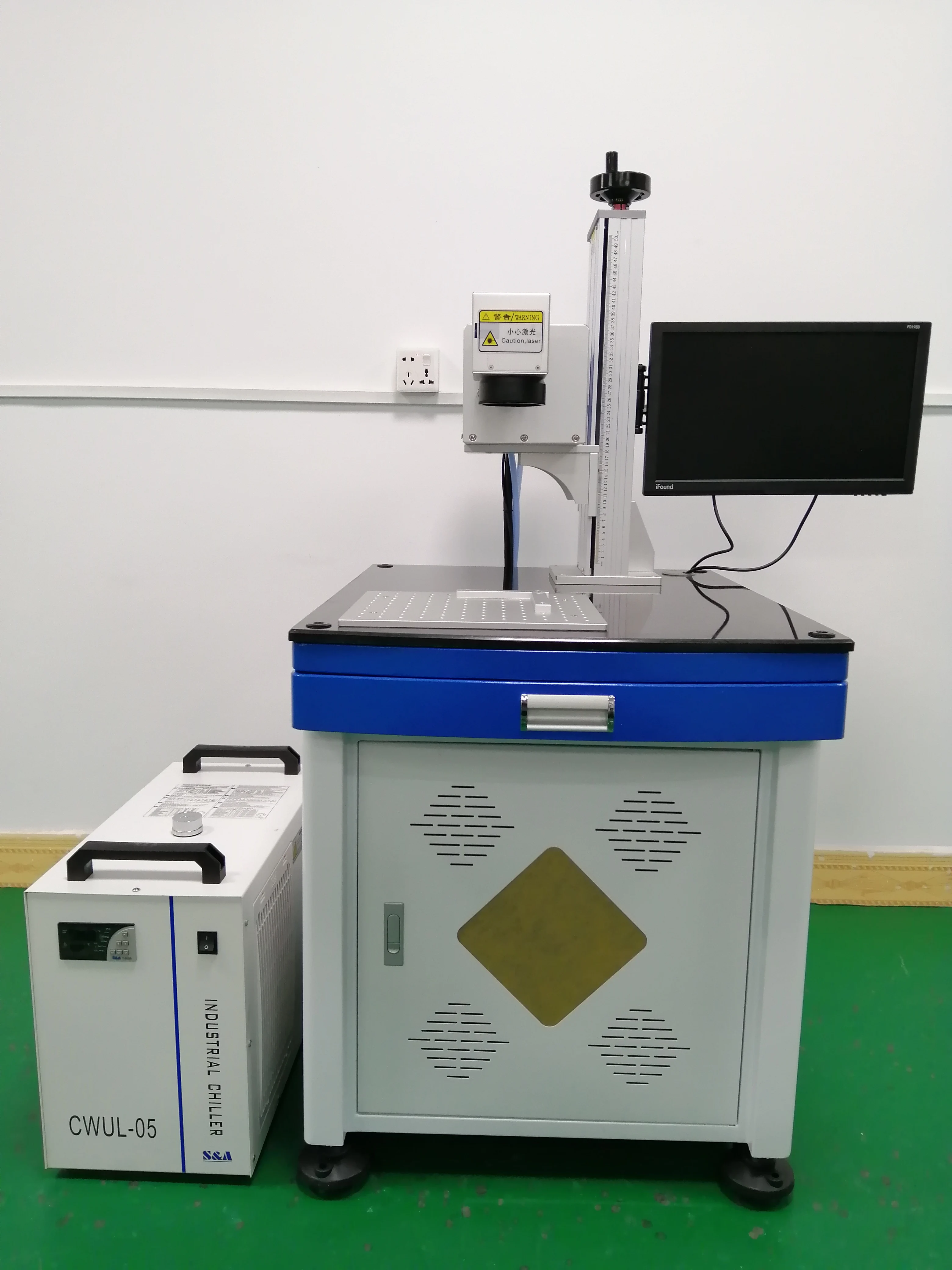

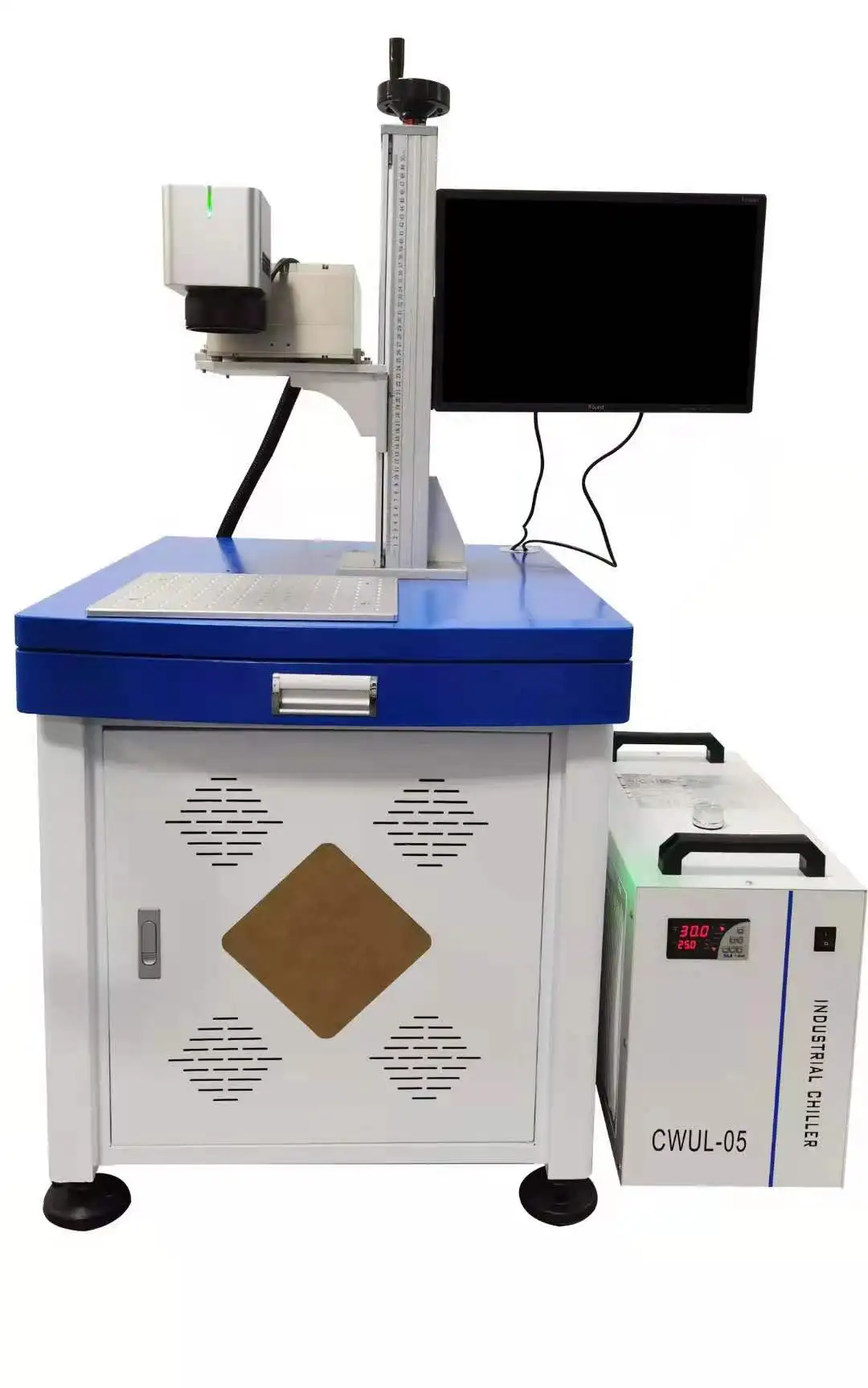

Laser Machine for powder flocking glass bottle

Production Features:

Reaction Mechanism of UV laser machining is achieved by photochemical ablation,

which rely on interrupting the laser energy bonding between atoms or molecules, a small molecule to become vaporized, evaporated. Focusing spot is extremely small, and the processing is minimal heat affected zone, which can be ultra-fine marking, marking special materials, the effect is the marking requirements of the customers have higher product of choice.

1: Wavelength of 355nm thermal effect on small workpieces, there will be no thermal

effect, thematerial deformation does not scorch, more suitable for the village of

thermal radiation quality products for processing large response

2: Spot meticulous precision, coupled with high-precision marking head

configuration makes marking the effect of near-perfect

3:High beam quality, focusing spot is very small, can achieve ultra-fine marking

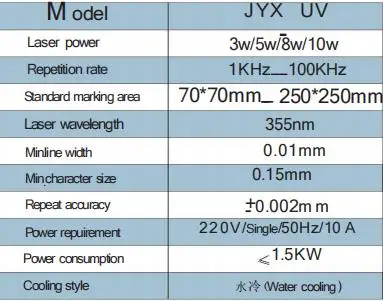

Product Specification:

Product Pictures:

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Other Hot Selling Equipment :

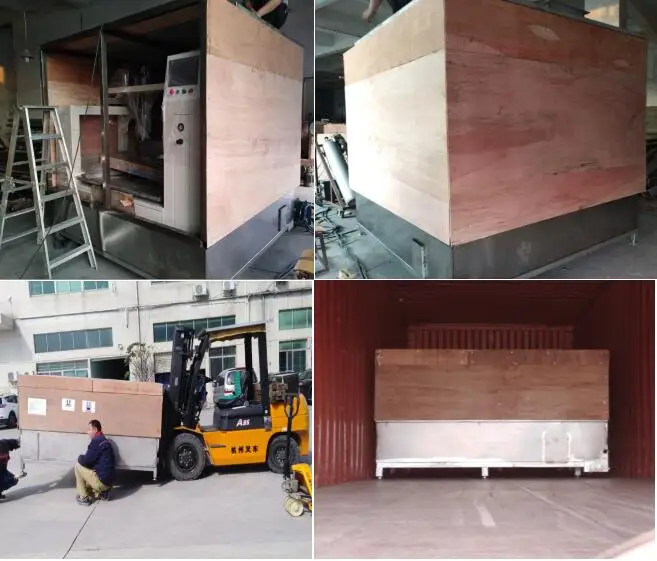

Packageing & Shipping:

it will packed by the vacuum membrace firstly, Then use the square box section to fixed,finnaly the equipment will be sealed with the wooden frame.

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household

appliances, medical equipment, metal products, construction machinery, mechanical and

electrical products, motorcycles and other metal products, wooden furiture, plastic products

and other types of products.

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

FAQ

Question 1: I don't know anything about the machine. Will you provide the technical support?

Answer: Sure. Every machine will be test before delivery. We will make sure there is no problem for the machine while it leave our factory.

When the equipment is small and standard ,such as five axis spraying equipment,mini spraying line, small tunnel furnance or ovens,spraying power booth,curing furnace etc, We can send the detailed user manual and video to

help you install and operate the equipment. Of course,You can arrange 2-3 smart workers to come to our factory to learn how to operate the machine.

If the machine is spraying line and big,When the machine arrives your factory, we will send the experts to your factory to help for installation and commissioning. Operation training will be provide. Maintenance tips will be given and enough spare parts be provided.

Also, we provide consulting service for creating the proper facilities for running the machine.

Question 2: What is price of the machine?

Answer: Normally, Most of the machine is customized for our customer. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please send us the detail infos about your workpiece as blow:

1. The maximum size of workpiece:

2. The max weight of workpiece:

3. The output per month/per day:

4. Heating Temperature and Time(If you need the drying equipment):

5. Color changing(How many colors? How long will it take to change other colors ?)

6. Spraying process(What paint will you use? Spraying times? )

7. The workshop size for the equipment:

8. Some work-piece pics are needed:

9. The power: industrial three phase voltage

10. Other requirements from customer:

We will provide our professional suggestions and work out an appropriate design for your project.

Then the quotation with detail specification will be offered to you ASAP.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ