Overview

Inquiry

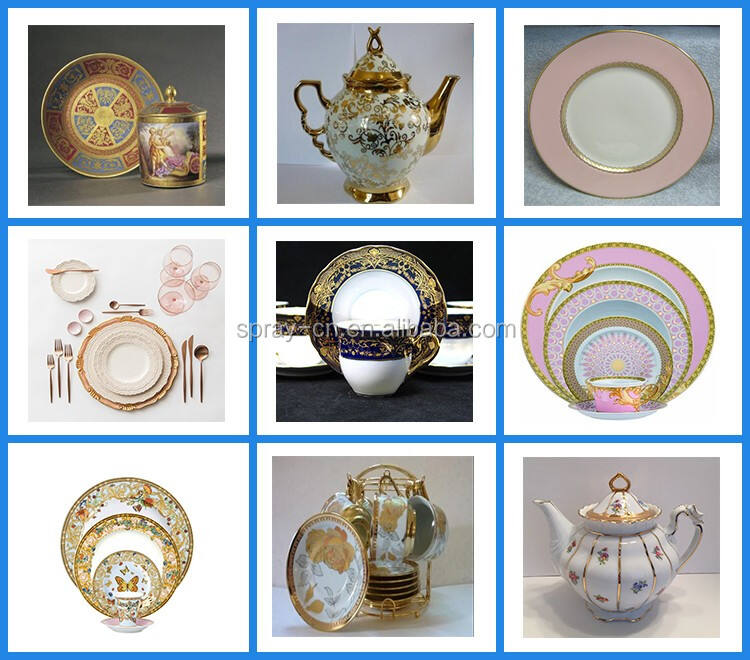

Related Products

The Xinqinfeng Metal Hardware PVD Vacuum Coating Machine may be a sophisticated and device that is efficient lets you metal that is coating with top-notch and durable films via a physical vapor deposition (PVD) process.

This machine is specially developed to meet with the needs of companies that require metal coatings with superior quality, opposition, and performance. This product is able to deposit different materials onto metal surfaces, including metals, ceramics, and plastics featuring its high level PVD technology. This enables that you achieve a mixture this is certainly wide of, from metallic colors to colorful and ornamental coatings which may be perfect for various applications.

Crafted from top-notch materials and built to last, the Xinqinfeng Metal Hardware PVD Vacuum Coating Machine offers value that is great your internet business. It features a steel that is stainless that may withstand temperatures that are high pressures, making sure the equipment can manage demanding applications consistently.

Furthermore, this device consists of a vacuum this is certainly top-of-the-line that will help to ensure that the metal areas are without any contaminants, allowing the coatings to stick to your substrate more effectively. The Metal Hardware PVD Vacuum Coating Machine also eliminates any gases or undesirable particles that could hinder the PVD procedure, making sure you can get a finish that is ideal time.

Additionally, the Xinqinfeng Metal Hardware PVD Vacuum Coating Machine was made to be easy to use, rendering it something which is perfect both novices and professionals. The control this is certainly intuitive enables you to set the desired running parameters easily, including coating depth, deposition rate, and cleaner level. The unit is also sold with accuracy temperature and force sensors, which makes it very easy to monitor and adjust the method as required.

The Xinqinfeng brand name is known for its quality that is exceptional and, and this Metal Hardware PVD Vacuum Coating Machine isn't any exclusion. It boils down insurance firms an assurance that is after-sales that are comprehensive services to make sure that you have many out of the investment.

| Production Features: |

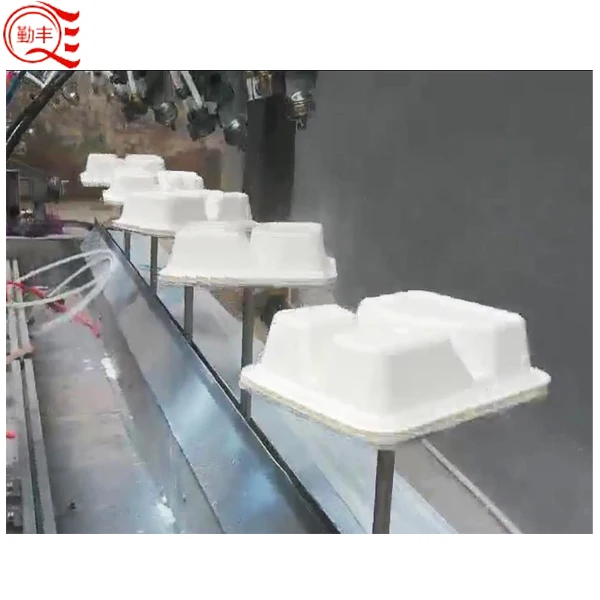

Evaporation coating equipment: vertical, horizontal. Machinable products include: mobile phone, DVD, MP3, PDA shells, buttons; cosmetic shells; craft gifts, toys, Christmas gifts; Machinable materials include: ABS, PS, PP, PC, PVC, nylon, metal, Poly , glass, ceramics, TPU, etc. The electroplating effects are: ordinary electroplating bright surface, matte surface (semi-dumb, full-dumb), process electroplating wrinkles, wire drawing, raindrops, colorful, etc.; electroplating colors are: gold, silver, red, blue, green, purple, etc.

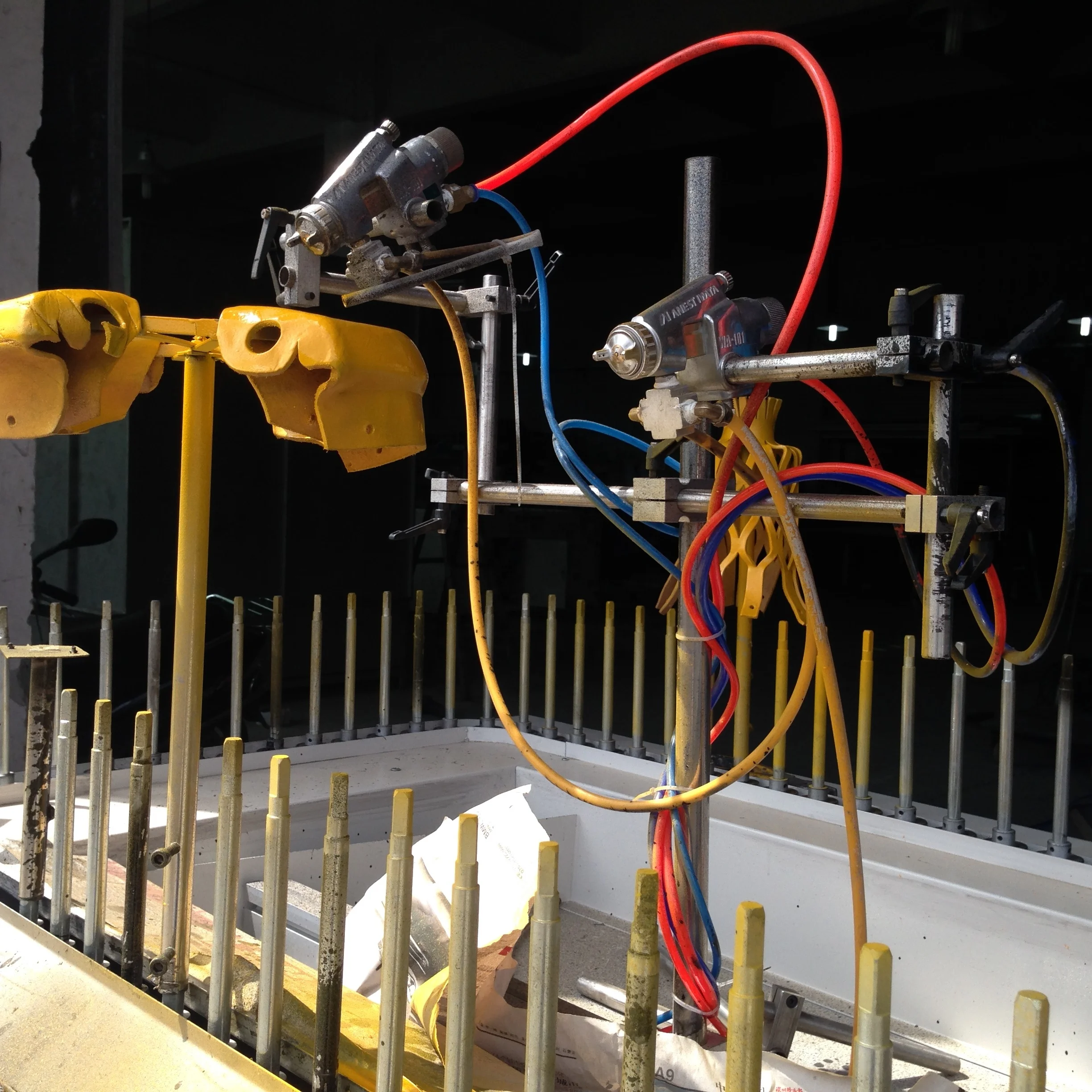

Magnetron sputtering + evaporation coating equipment: vertical, horizontal. It is a multifunctional and efficient coating equipment. Rotary magnetron rake, middle rake twin sputtering rake, unbalanced magnetron sputtering rake, DC pulse superimposed bias power supply, etc. can be configured according to user requirements. , glass, ceramics, etc.) workpieces coated with aluminum, copper, chromium, titanium, silver, stainless steel and other metal films or non-metallic and metal-infiltrated DLC films, the coating layer is uniform, dense, and has strong adhesion and other characteristics, which can be widely used in Home appliances, clocks, arts and crafts, toys, car lamp reflectors, mobile phone button shells and instrumentation and other surface decorative coatings and functional coatings for tools and molds.

Multi-arc ion coating equipment: We have matured in the design and processing of this coating equipment, and have been stable in the coating and coating of tools for a variety of ultra-hard ceramic films, including titanium nitride (Tin), titanium carbide (Tic), titanium nitride (Titanium carbide) ( TiCn), zirconium nitride (Zrn), chromium nitride (Crn), titanium aluminum nitride (TiAln), etc. After proper film processing, the life of the workpiece can be increased by 3 to 10 times. It can reduce costs, increase production efficiency and improve product quality. Widely used: craft ceramics, cutting tool industry: such as carbide, drill, milling cutter and other cutting tools. Precision mold industry: standard punch molds, forming molds, etc. Automobile industry: easy-wear parts such as pistons and piston rings.

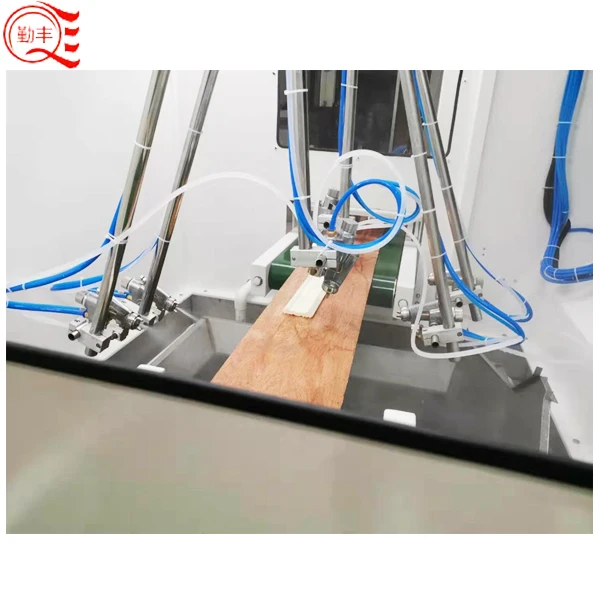

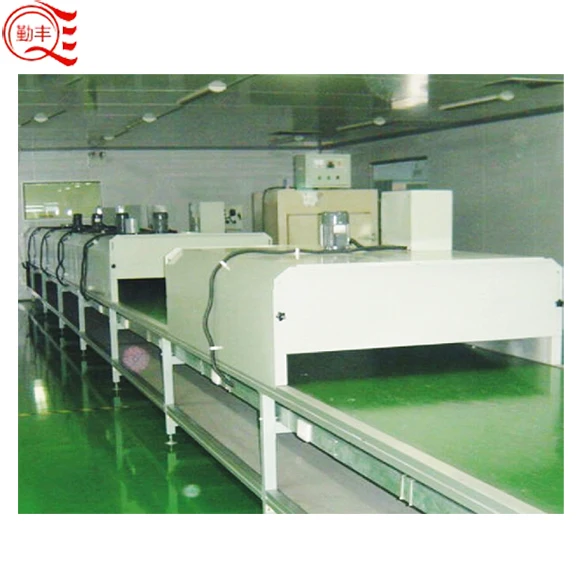

| Spray the base UV paint---UV Curing----PVD Vacuum coating machine----Spray the top UV paint---UV curing. |

Overview: Evaporative coating device uses resistance heating method in a vacuum chamber to melt and vaporize the metal wire (aluminum wire) that is close to the resistance wire, and the vaporized metal molecules are deposited on the substrate to obtain smooth and high reflection. The high-efficiency film layer achieves the purpose of decorating and beautifying the surface of the item.

Features: Reasonable structure, uniform film layer, good film quality, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption and stable performance.

Uses: automobiles, audio, various small appliances, computers, watches, toys, mobile phones, reflectors, cosmetics, toys and other industries.

Machinable materials: ABS, PS, PP, PC, PVC, Nylon, Metal, Poly, Glass, Ceramic, TPU, etc.

| Product Pictures: |

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ