Overview

Inquiry

Related Products

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

- Manipulator, Spraying robot etc Industrial Robot equipment

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

Xinqinfeng

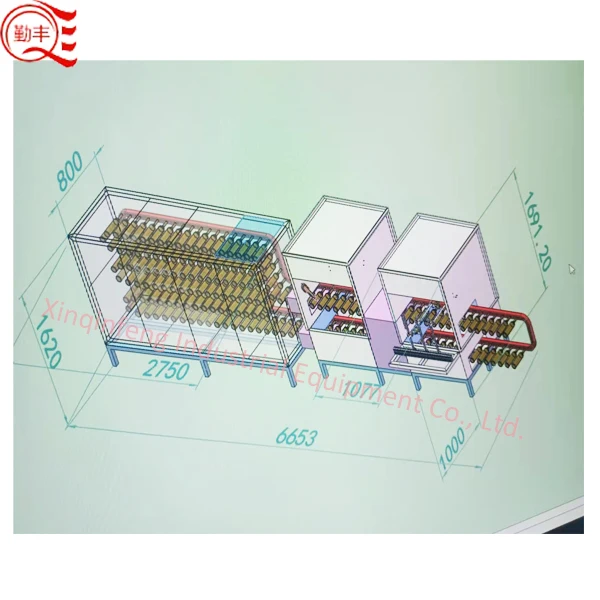

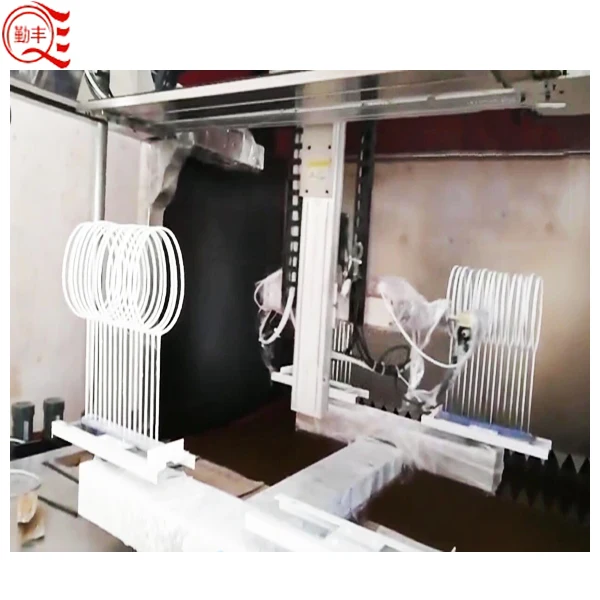

Powder Flocking Auto Spraying and Drying Line could be the solution is certainly perfect for any company attempting to streamline their production process and increase the quality of these products. This technique is innovative built to provide you with the ultimate finishing touch to your products or services, creating a sensational, smooth, and even surface that's certain to wow your customers.

The system is extremely easy to use, making it well suited for organizations of all the sizes. The event is big is auto-spraying that the powder can be used evenly, without any mess or waste. The flocking procedure normally fully automatic, making certain the flocking product is applied evenly and correctly.

The method is drying equally impressive. Because of the higher level technology that drying the system is able to dry products and services quickly and effectively, making certain they've been ready for further processing or shipping very quickly at all. Therefore you are able to raise your production ability while keeping the most effective degrees of product quality.

Among the primary benefits of the Xinqinfeng Powder Flocking Auto Spraying and Drying Line is its flexibility. The device can be simply personalized to generally meet the particular requirements of your company and services and products. All of it whether you utilize little or services are large products, complex or simple designs, the product has the ability to handle.

The Xinqinfeng Powder Flocking Auto Spraying and Drying Line is manufactured use is making of which are top-notch components, making certain it is durable and long-lasting. The equipment can be incredibly very easy to keep, by way of its easy design and performance is reliable.

| Production Features: |

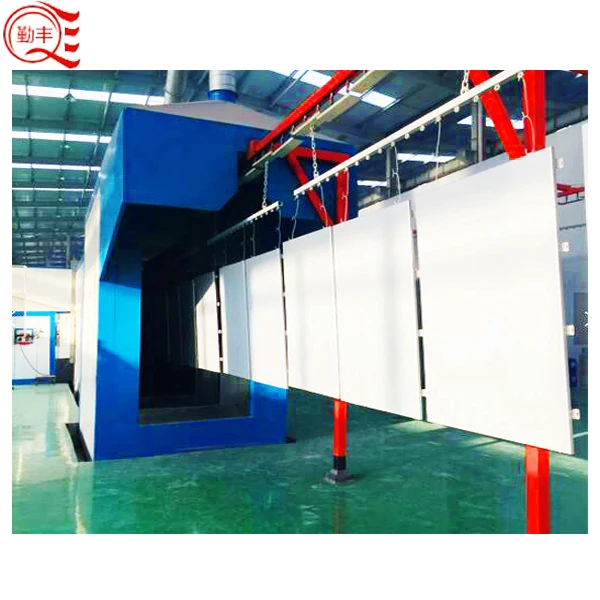

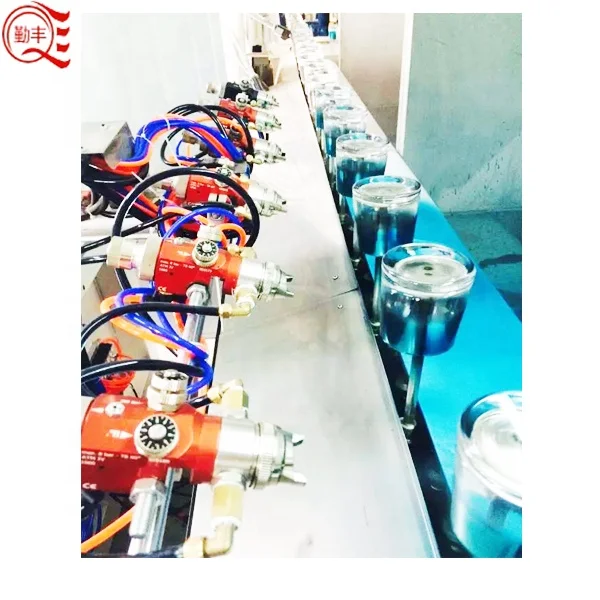

fully automatic Glass bottle(Other product also can be designed) flocking production line

Main features and advantage of automatic glass bottle production line

1.The sealing design of flocking cabinet can ensure the working environment is clean and dust-free. eco-friendly and keep health to operating workers.

2.Automatic flocking machine with automatic gluing system, daily output can up to 3000-4000 pcs per day, saving your labor cost and time.

3.designed for flocking on different glass bottle,perfume bottle,Wine bottle,Comestic bottle,cup etc.

4. User friendly design, convenient operation.

Features of electrostatic flocking

Electrostatic flocking is a surface decoration method in which the fiber fluff is polarized by an electrostatic field, and the polarized fluff is neatly erected on the surface of the glued substrate along the power line, and fixed on the surface of the substrate after drying. The surface of the wood-based panel substrate can be beautified by electrostatic flocking, the defects on the surface of the substrate can be covered, and the variety of colors on the surface of the wood-based panel can be increased. Flocking products have a style similar to embroidery, suitable for advanced interior decoration, such as wall, ceiling, countertop, etc., can be used for furniture decoration, protect the surface of high-end products such as instruments, meters, musical instruments, etc., and can also be made into arts and crafts, such as Three-dimensional surfaces such as calligraphy, paintings, and patterns.

According to the different flocking products, choose the appropriate flocking method, generally divided into three types:

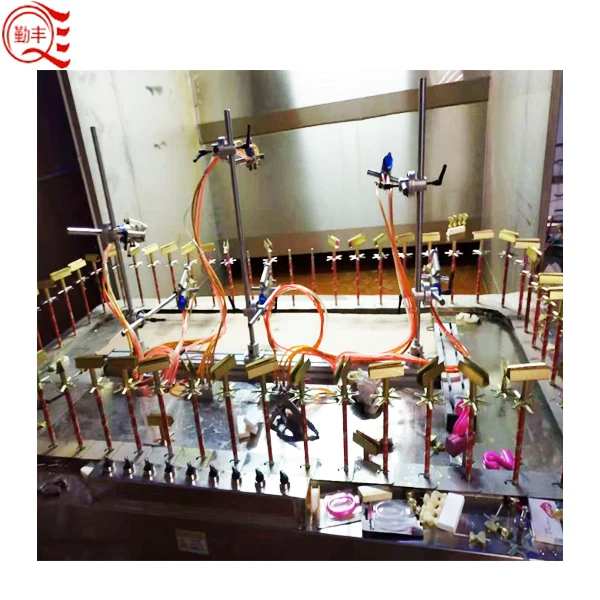

1. Flocking machine line-type flocking: The flocking line can realize the automatic completion of gluing, flocking, drying, and flocking removal of items at one time, such as: flocking cloth, leather, paper, non-woven fabric , PVC, blister sheets, sponges, various handicrafts, toys, automotive plastic parts, storage boxes, automotive sealing strips, decorative strips, blister boxes, cardboard, calendars, couplets, New Year pictures, flocking of packaging gift boxes printing.

2. Box-type flocking: According to the size and shape of the flocked product, a flocking box is made, the fluff is placed in the box, and the power is turned on, so that a high-voltage electric field is formed in the flocking box, and the flocked product is flocked from the flocking box. One end of the box is sent into the box, and after three to five seconds, the flocking is completed and then removed from the other end of the box, and the finished product is dried or dried.

3. Nozzle flocking: connect the power supply, and output tens of thousands of volts of high-voltage static electricity generated by the flocking machine to the industrial nozzle. The fluff in the nozzle is negatively charged, and then the surface of the plant body is sprayed with adhesive. The nozzle is close to the flocked object, and the fluffs fly from the nozzle to the surface of the flocked object under the action of a high-voltage electric field, and are vertically planted on the surface of the object coated with the adhesive.

| Product Pictures: |

| Application: |

The field of flocking industry is very broad, and the representative industries are:

1. Handicraft industry: toys, handicrafts, photo frame backboards, gifts, craft calligraphy and painting, artificial flowers, craft plastic lanterns, etc. of various styles and materials.

2. Packaging industry: jewelry boxes, health product packaging boxes, wine boxes, glasses boxes, marriage certificates, high-end certificate skins, wine bottles, luggage, stickers, cardboard (board), etc.

3. Automotive industry: automotive rubber seals, automotive interior plastic parts, etc.

4. Other industries: motorcycle helmets, hangers, fire doors, safes, lamps, cabinets, sanitary ware, furniture, sponges, EVA, hangers of various materials, etc.

5. Resin, ceramics, gypsum, glass, plastic, recycled plastic handicrafts, flocking on the surface of toys

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household

appliances, medical equipment, metal products, construction machinery, mechanical and

electrical products, motorcycles and other metal products, wooden furiture, plastic products

and other types of products.

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

If you can send us some pics about your product with capacity per day and size for first reference. Once get your infos, We will send you our solution with price ASAP.Appreciating for your support!

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ