Overview

Inquiry

Related Products

Launching the Xinqinfeng Vertical Single Door Multi-Arc Ion Vacuum Coating Device this method that is ideal that is revolutionary people who are purchasing a dependable and device that is efficient apply top-notch coatings onto an array of areas. This system that is function that is revolutionary perfect solution for the final outcome requires whether you might be a professional to your automotive industry or a musician wanting to produce unique pieces.

The Vertical Single Door Multi-Arc Ion Vacuum Coating device is extremely easy to use. It includes a house that is correct is obviously single which enables effortless loading and unloading associated with things, making the layer procedure quite simple. To work well with the machine, simply put your item inside and choose the settings being appropriate apply the layer you prefer.

Among the list of many features of the Xinqinfeng Vacuum Coating unit is its ion that is technology that is effective multi-arc. This technology this is actually advanced level that the coatings which are specific utilized evenly and precisely every time. This device will make coatings with excellent adhesion, hardness, and wear resistance with just as much as eight arc sources and a charged energy supply system that is high voltage.

Another function this is really exceptional of Vertical Door that is solitary vacuum cleaner that is multi-Arc unit is its big capability. It would likely accommodate services and products just as much as 1100mm in height and 700mm in diameter, giving you a known degree that is excellent of to coating big and items that can easily be little.

Product Description

Production Features: |

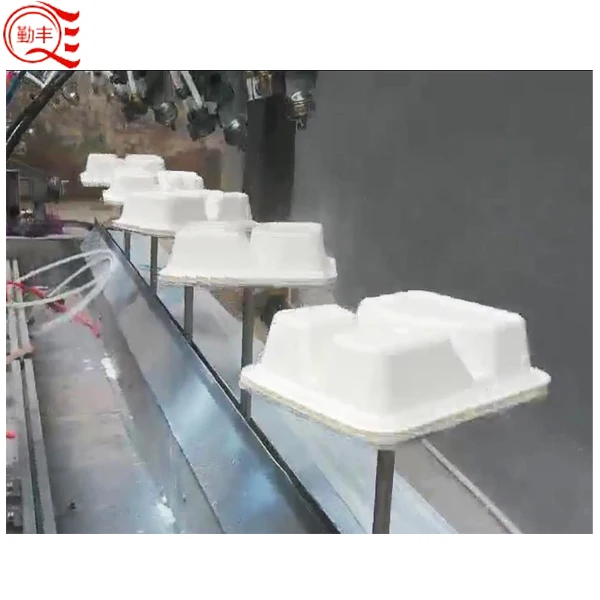

Evaporation coating equipment: vertical, horizontal. Machinable products include: mobile phone, DVD, MP3, PDA shells, buttons; cosmetic shells; craft gifts, toys, Christmas gifts; Machinable materials include: ABS, PS, PP, PC, PVC, nylon, metal, Poly , glass, ceramics, TPU, etc. The electroplating effects are: ordinary electroplating bright surface, matte surface (semi-dumb, full-dumb), process electroplating wrinkles, wire drawing, raindrops, colorful, etc.; electroplating colors are: gold, silver, red, blue, green, purple, etc.

Magnetron sputtering + evaporation coating equipment: vertical, horizontal. It is a multifunctional and efficient coating equipment. Rotary magnetron rake, middle rake twin sputtering rake, unbalanced magnetron sputtering rake, DC pulse superimposed bias power supply, etc. can be configured according to user requirements. , glass, ceramics, etc.) workpieces coated with aluminum, copper, chromium, titanium, silver, stainless steel and other metal films or non-metallic and metal-infiltrated DLC films, the coating layer is uniform, dense, and has strong adhesion and other characteristics, which can be widely used in Home appliances, clocks, arts and crafts, toys, car lamp reflectors, mobile phone button shells and instrumentation and other surface decorative coatings and functional coatings for tools and molds.

Multi-arc ion coating equipment: We have matured in the design and processing of this coating equipment, and have been stable in the coating and coating of tools for a variety of ultra-hard ceramic films, including titanium nitride (Tin), titanium carbide (Tic), titanium nitride (Titanium carbide) ( TiCn), zirconium nitride (Zrn), chromium nitride (Crn), titanium aluminum nitride (TiAln), etc. After proper film processing, the life of the workpiece can be increased by 3 to 10 times. It can reduce costs, increase production efficiency and improve product quality. Widely used: craft ceramics, cutting tool industry: such as carbide, drill, milling cutter and other cutting tools. Precision mold industry: standard punch molds, forming molds, etc. Automobile industry: easy-wear parts such as pistons and piston rings.

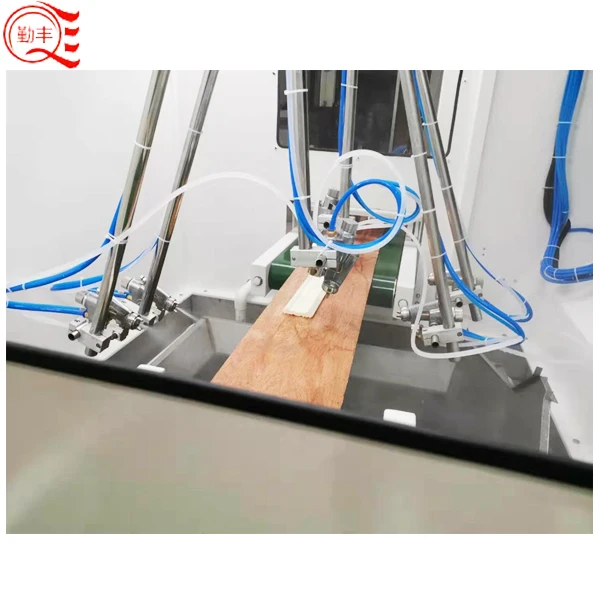

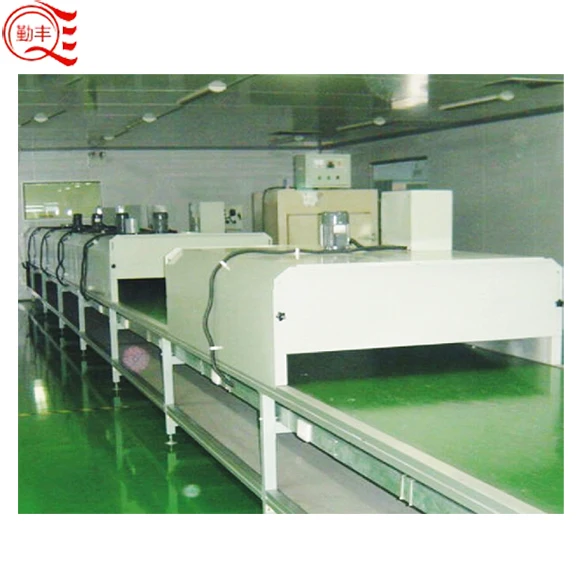

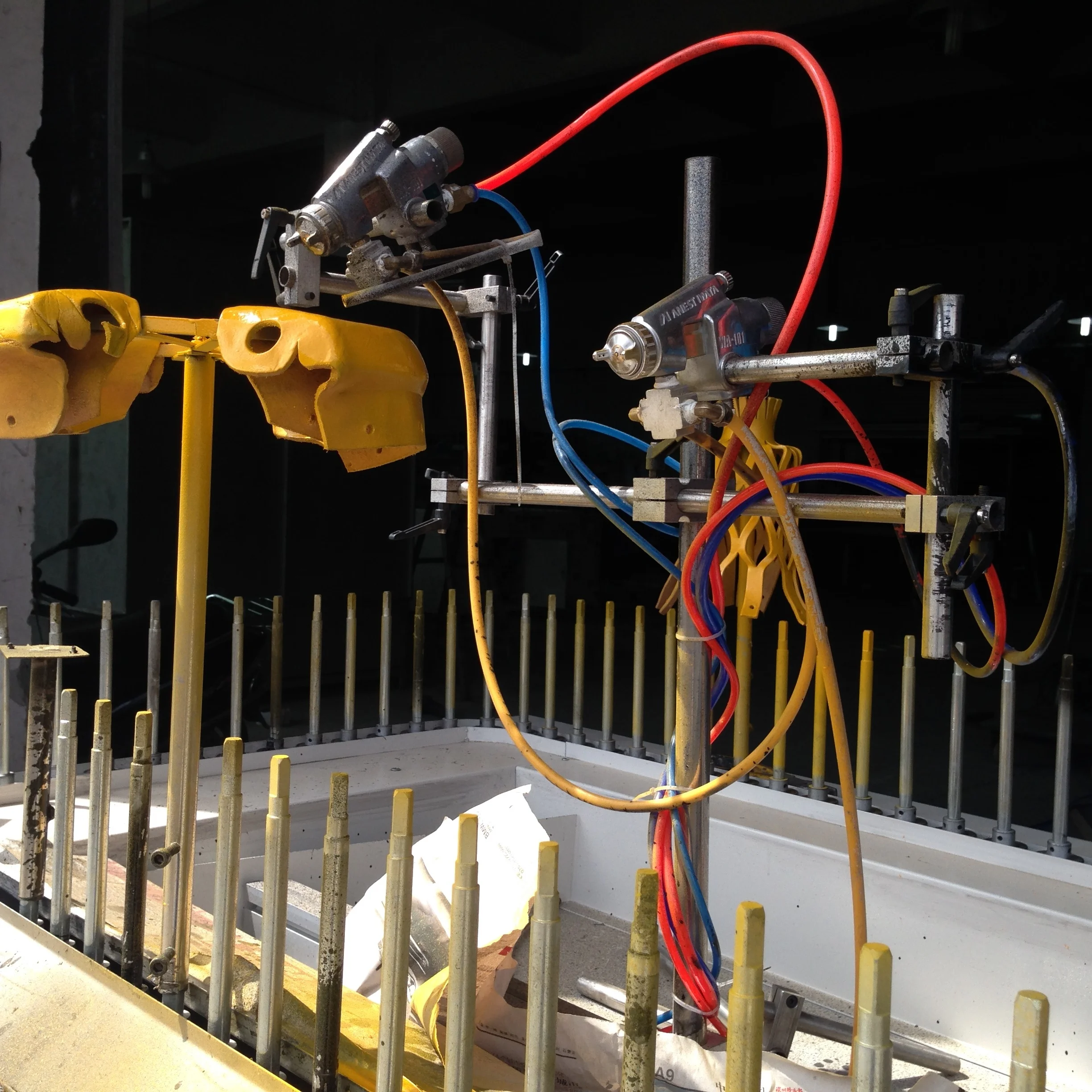

Process Flow of Spray Painting |

Spray the base UV paint---UV Curing----PVD Vacuum coating machine----Spray the top UV paint---UV curing. |

Overview: Evaporative coating device uses resistance heating method in a vacuum chamber to melt and vaporize the metal wire (aluminum wire) that is close to the resistance wire, and the vaporized metal molecules are deposited on the substrate to obtain smooth and high reflection. The high-efficiency film layer achieves the purpose of decorating and beautifying the surface of the item.

Features: Reasonable structure, uniform film layer, good film quality, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption and stable performance.

Uses: automobiles, audio, various small appliances, computers, watches, toys, mobile phones, reflectors, cosmetics, toys and other industries.

Machinable materials: ABS, PS, PP, PC, PVC, Nylon, Metal, Poly, Glass, Ceramic, TPU, etc.

Product Pictures: |

COATING APPLICATION

decorative coating machine can be applied to coat different colors and film on all kinds of stainless steel , glass , ceramic products , such as bathroon hardware , stainless steel straps ,jewelry, golf heads , stainless steel/ceramic tableware ,etc. if you need the super hard film tools coating , please choose our company Foxin .

Company Information

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries. From a development department, Xinqinfeng has become a professional manufacturer which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment. After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Our Service:

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1-year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

If you can send us some pics about your product with capacity per day and product size for first reference. Once get your info’s, We will send you our solution with price ASAP, Appreciating for your support

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ