Overview

Inquiry

Related Products

Xinqinfeng

Aluminum wine glass bottle vacuum coating machine is a product that outstanding was created to offer vacuum is top-quality for aluminum containers as well as other glass containers. This system is made to provide you with an amount is a lot of, durability, and reliability you want to coat full confidence to your containers.

This method is fantastic for those that need to get their containers coated in an even more efficient and method in which is effective. It is well suited for covering an array of bottles, including wine bottles, beer bottles, as well as other glass bottles made out of aluminum. The Xinqinfeng Aluminum wine glass bottle vacuum coating machine is sold with features making it simple for yourself to definitely use and acquire the job is working quickly.

These devices was created to be user-friendly and includes a control is simple that you can use to the office the device. This control board offers you everything is important you will want to complete the job. You can easily create and needs upkeep is rendering that minimal a great selection for businesses and people which do not need plenty of time to invest in upkeep.

The Xinqinfeng Aluminum wine glass bottle vacuum coating machine is manufactured out of top-notch materials that ensure its durability. This machine is built to final and can provide you with many years of service without deteriorating. It really is compact in proportions and it is built to use up room is minimal your workspace.

An extra function is very good device for its energy efficiency. It’s created to utilize less power, which makes it affordable to use plus is environment-friendly. The Aluminum wine glass bottle vacuum coating machine features a cooling that special will help to stop the overheating in connection with device and means that it will continue to operate effectively.

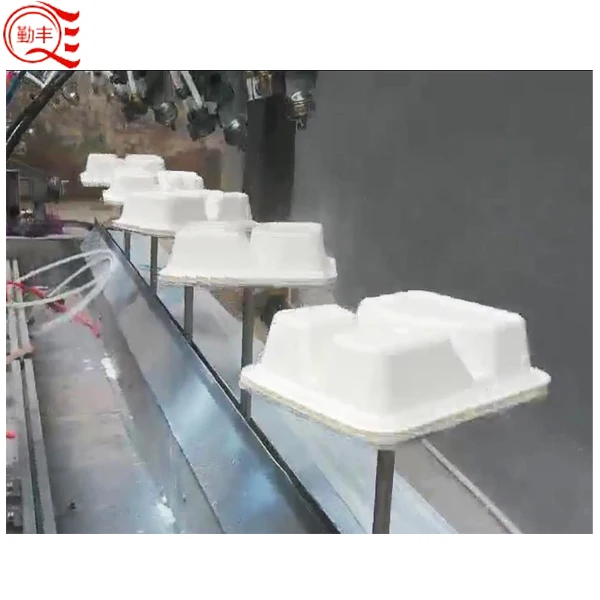

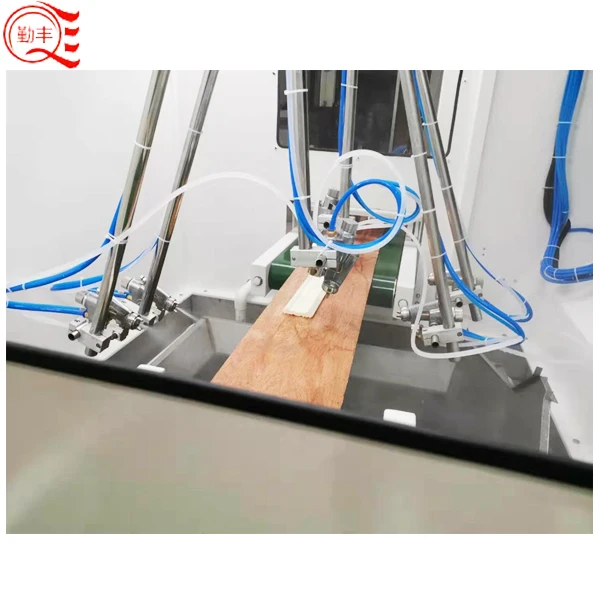

Evaporation coating equipment: vertical, horizontal. Machinable products include: mobile phone, DVD, MP3, PDA shells, buttons; cosmetic shells; craft gifts, toys, Christmas gifts; Machinable materials include: ABS, PS, PP, PC, PVC, nylon, metal, Poly , glass, ceramics, TPU, etc. The electroplating effects are: ordinary electroplating bright surface, matte surface (semi-dumb, full-dumb), process electroplating wrinkles, wire drawing, raindrops, colorful, etc.; electroplating colors are: gold, silver, red, blue, green, purple, etc.

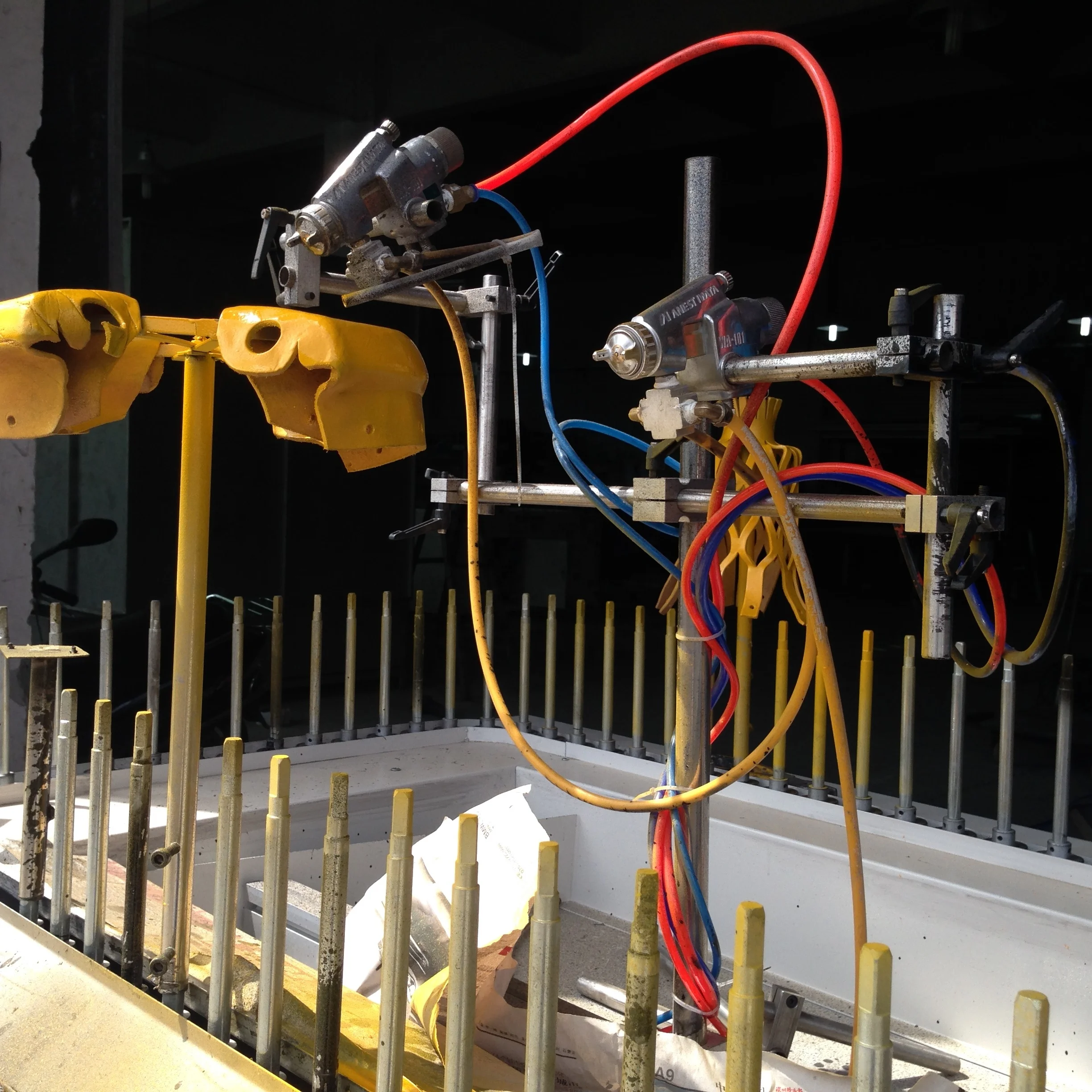

Magnetron sputtering + evaporation coating equipment: vertical, horizontal. It is a multifunctional and efficient coating equipment. Rotary magnetron rake, middle rake twin sputtering rake, unbalanced magnetron sputtering rake, DC pulse superimposed bias power supply, etc. can be configured according to user requirements. , glass, ceramics, etc.) workpieces coated with aluminum, copper, chromium, titanium, silver, stainless steel and other metal films or non-metallic and metal-infiltrated DLC films, the coating layer is uniform, dense, and has strong adhesion and other characteristics, which can be widely used in Home appliances, clocks, arts and crafts, toys, car lamp reflectors, mobile phone button shells and instrumentation and other surface decorative coatings and functional coatings for tools and molds.

Multi-arc ion coating equipment: We have matured in the design and processing of this coating equipment, and have been stable in the coating and coating of tools for a variety of ultra-hard ceramic films, including titanium nitride (Tin), titanium carbide (Tic), titanium nitride (Titanium carbide) ( TiCn), zirconium nitride (Zrn), chromium nitride (Crn), titanium aluminum nitride (TiAln), etc. After proper film processing, the life of the workpiece can be increased by 3 to 10 times. It can reduce costs, increase production efficiency and improve product quality. Widely used: craft ceramics, cutting tool industry: such as carbide, drill, milling cutter and other cutting tools. Precision mold industry: standard punch molds, forming molds, etc. Automobile industry: easy-wear parts such as pistons and piston rings.

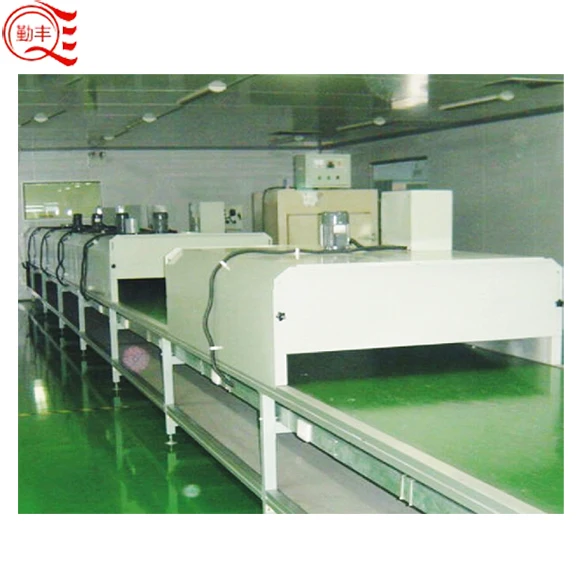

| Spray the base UV paint---UV Curing----PVD Vacuum coating machine----Spray the top UV paint---UV curing. |

Overview: Evaporative coating device uses resistance heating method in a vacuum chamber to melt and vaporize the metal wire (aluminum wire) that is close to the resistance wire, and the vaporized metal molecules are deposited on the substrate to obtain smooth and high reflection. The high-efficiency film layer achieves the purpose of decorating and beautifying the surface of the item.

Features: Reasonable structure, uniform film layer, good film quality, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption and stable performance.

Uses: automobiles, audio, various small appliances, computers, watches, toys, mobile phones, reflectors, cosmetics, toys and other industries.

Machinable materials: ABS, PS, PP, PC, PVC, Nylon, Metal, Poly, Glass, Ceramic, TPU, etc.

Is it safe to order from XINQINFENG? Yes, 100% sure you are safe to order from us. XINQINFENG exported too many countries and we are the famous factory produce spray equipment more than 17 years in China.

How to delivery?

By sea for big order, by courier for small order, by airlines.

How to pay?

We accept the PayPal (but credit card not accepted), Western Union, Bank transfer, money gram, etc.

Which model should I choose?

When spray especially metallic powders, according to your product shapes and the coating job details. For example, need to change colors often or only few colors, then choose the box feed unit or hopper feed unit. The small hopper unit is good for lab test or small work.

Can I customized the machines?

Yes, we are a professional team for powder coating equipment’s, our technician will design for you especially according to your needs and your factory, workpiece etc. information.

What should I offer if I want to customize the machine?

a. Your factory available for the equipment dimension by L x W x H

b. Your max workpiece or product weight and size by L x W x H

c. Your product surface condition (with oil or dust?) and some pictures if possible

d. Your output capacity (for machine line)

e. Your industrial electric power in V-Phase-Hz.

Can you install for us?

Yes, we can install overseas for you. But the engineers overseas installation cost, round trip air tickets, accommodation, meals and transport charges are on the buyers.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ