Overview

Inquiry

Related Products

Brand: Xinqinfeng

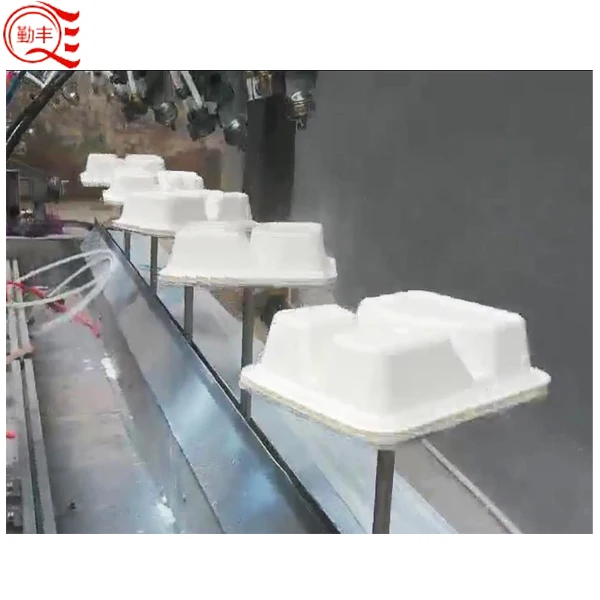

The Xinqinfeng Automatic Rack, Barrel and Reel-to-Reel Plating Line Machine is truly a product this is certainly advanced for plating elements that are industrial parts in big amounts. The unit is especially meant to offer reliable and steel this is certainly high-quality when it comes to number of components screws that are including nuts, bolts, along with other steel components.

The Xinqinfeng Automatic Plating Line Machine is extremely efficient and effective in providing a surface that is amazing for steel components and parts having its advanced technology and features. The machine features a completely automated procedure that improves the productivity for the manufacturing line, decreases the risk of errors, and effortlessly supplies a plating this is certainly high-quality while maintaining precision and accuracy.

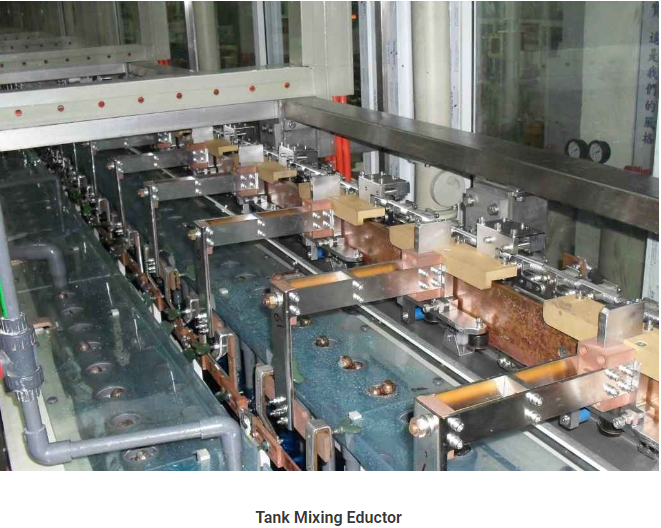

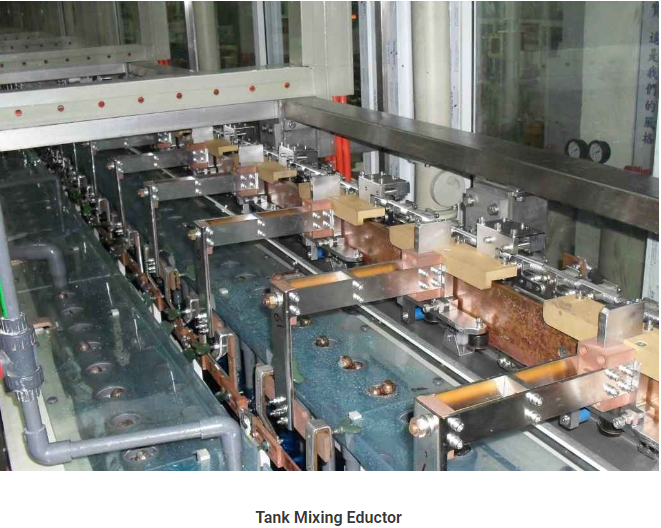

The Automatic Rack, Barrel and Reel-to-Reel Plating Line Machine is designed with features such as automated loading and unloading of parts, automated barrel transfers, barrel rotation, and chemical dosing control. These features ensure that the equipment operates regularly and offers a uniform finish on all metal parts and elements.

Also, the Xinqinfeng Automatic Plating Line Machine offers flexibility this is certainly accommodate high parts and services and products for plating. The equipment can accommodate areas of various sizes and shapes and certainly will offer coating this is certainly numerous on a single component, such as nickel, tin, silver, and copper plating.

The Xinqinfeng Automatic Plating Line Machine is easy to utilize, operate, and maintain. It is actually developed to work seamlessly along with other machines into the manufacturing line. A control is had by the device that is user-friendly that allows operators to monitor and obtain a grip from the plating process effortlessly. The Xinqinfeng brand is just a well-established and name brand this is certainly well-known the industry, with a track that is successful of top-notch products.

Automatic Rack, Barrel and Reel-to-Reel Plating Lines

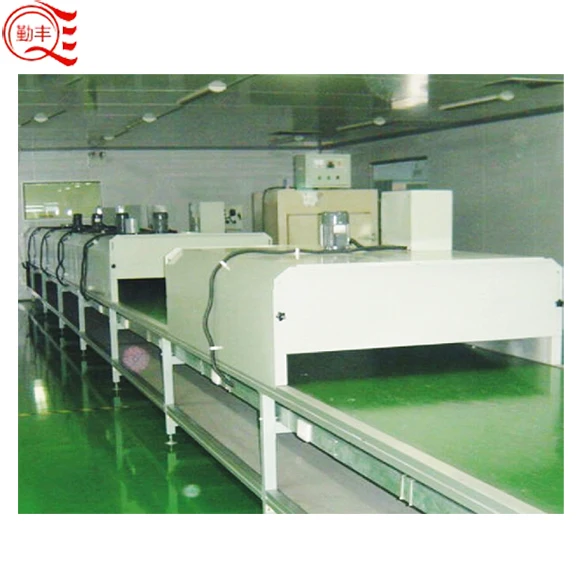

Electroplating or surface finish treatment has been widely adopted to produce a broad range of industrial coatings for both decorative and functional applications. Electroplated nickel is used on integrated circuits, microprocessors, and connectors to produce high solderability and corrosion resistance. In addition, it helps prevent short circuits and improves electrical conductivity.

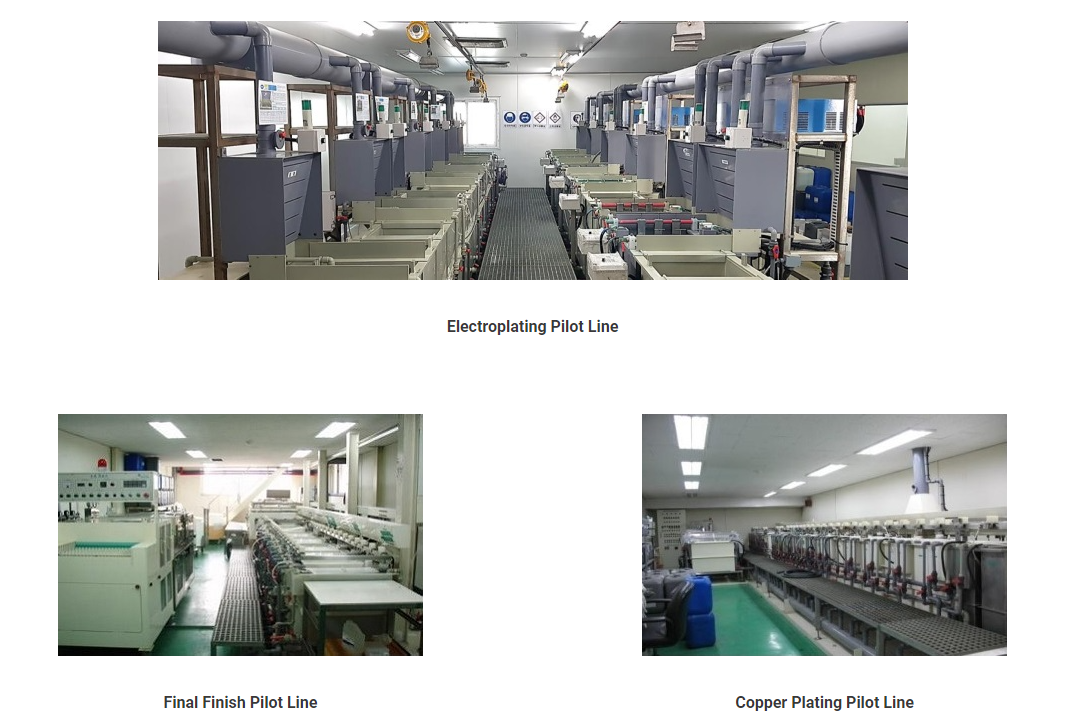

Our range of automated electroplating equipment includes rack, barrel, and reel-to-reel plating lines, which contain carriers and barrel moving solutions to increase process efficiency and productivity. All of our systems are equipped with PLC touchscreens that allow user control over initiating and managing dip time per tank, carrier transfer, and other processes.

We provide electroplating solutions and equipment to a wide range of global clientele who manufacture mobile phones, semiconductors, automotive components, consumer electronics, and PCBs. We have installed fully and semi-automated equipment lines for 143 clients at over 300 plants across the globe.

Spray paint machine -Nancy Xu:

Plate-on-Plastics | Applications | Processes

Plating on ABS Applications:

Home appliance parts including refrigerator and washing machine exterior parts such as trims, door grills, handles and buttons, and TV frames.

Automotive exterior and interior parts: trim, handles, emblems.

Electronics parts Plating on ABS Processes:Ni-Cr ABS Coating,Ni-3-Cr Plating,Ni-Au Plating,

ABS Plating with Direct Trivalent + Hexavalent Plating on PCB Applications:

Semiconductors

PCBs

Plating on PCB Processes:

Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

Soft ENIG Process

Tin Process

Electroless Copper Process

ENEPIG Ni-Au

PATTERN Cu

ENAG Ni-Au

Electro Ni-Au

Pattern Copper Plating

Plate-Thru-Hole (PTH) Plating

Plate-on-Metal | Applications | Processes

Plating on Steel, Stainless Steel, Aluminum and Alloy Applications:

Automotive components: engine components, shafts, piston pins, shock absorbers, cylinders, brake pistons and gears, turbochargers, and fuel systems

Motorcycle: brake calipers and wheels

Razor blades

Plating on Metal Processes

Hard Chrome Anodizing

Electrolytic Zinc-Nickel

Electroless Nickel Plating: Nickel Chloride Base and Nickel Sulfate Base

Cu-Cu-Ni-Cr Plating

Other Surface Treatment Line Applications and Processes:

Desmear for PCB

Plating on rubber for automotive wipers

We offer two types of solutions for electroless nickel plating, one with a nickel chloride base and the other with a nickel sulfate base. Electrolytic zinc-nickel and electroless nickel-plating solutions are used to plate on metals and are effective for corrosion protection.

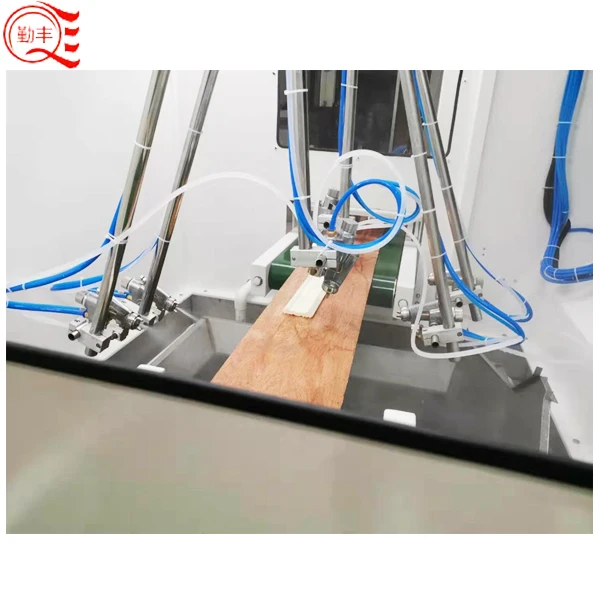

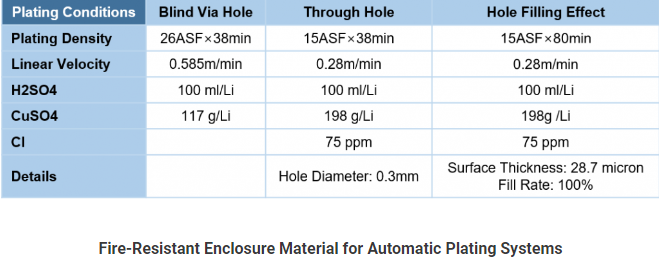

Vertical Type Continuous Copper and Nickel Electroplating Line for HDI, FPC, and FPCB Coating

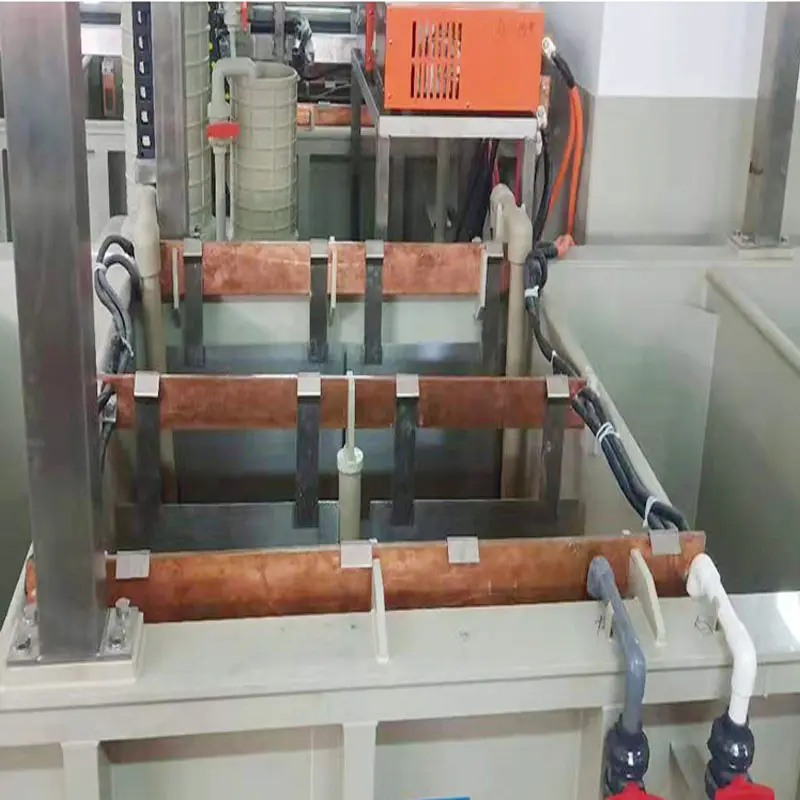

The vertical type continuous plating lines are fully automated and maintain strict thickness uniformity copper and nickel coating solutions. They are designed to be used with both insoluble and soluble anodes. Copper and nickel electroplating lines are frequently used for mass manufacturing pro

Spray paint machine -Nancy Xu:

Copper and nickel electroplating lines are frequently used for mass manufacturing production lines of integrated circuits, microprocessors, and connectors. For example, nickel plating is applied to FPCB insulation to minimize electric signal breakage by preventing whiskers.

Our exemplary clients who are currently using the vertical type Electroless Nickel Immersion Gold plating line include Korea Circuit, LG Innotek, Interflex, and Samsung Electronics.

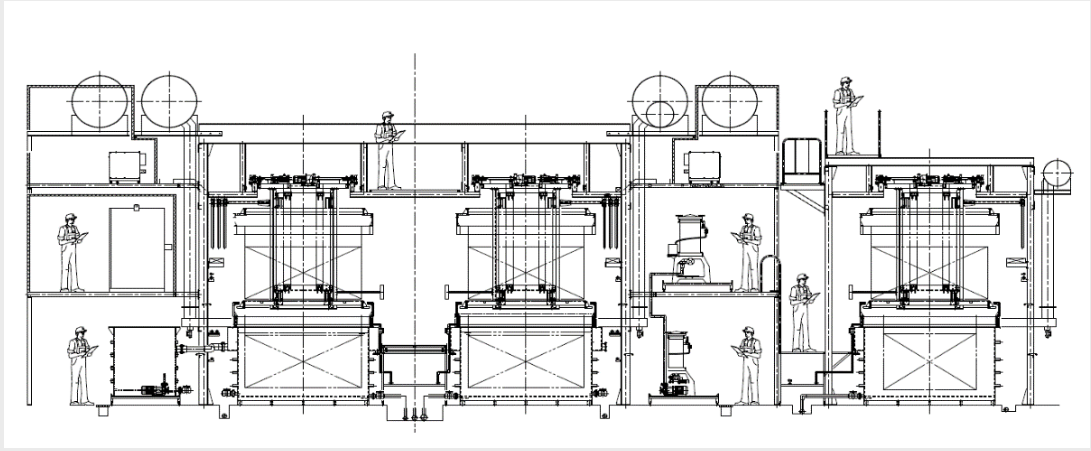

The plating systems are enclosed with fire-resistant materials and the exhaust systems are connected to all chemical tanks to ensure a safe environment.

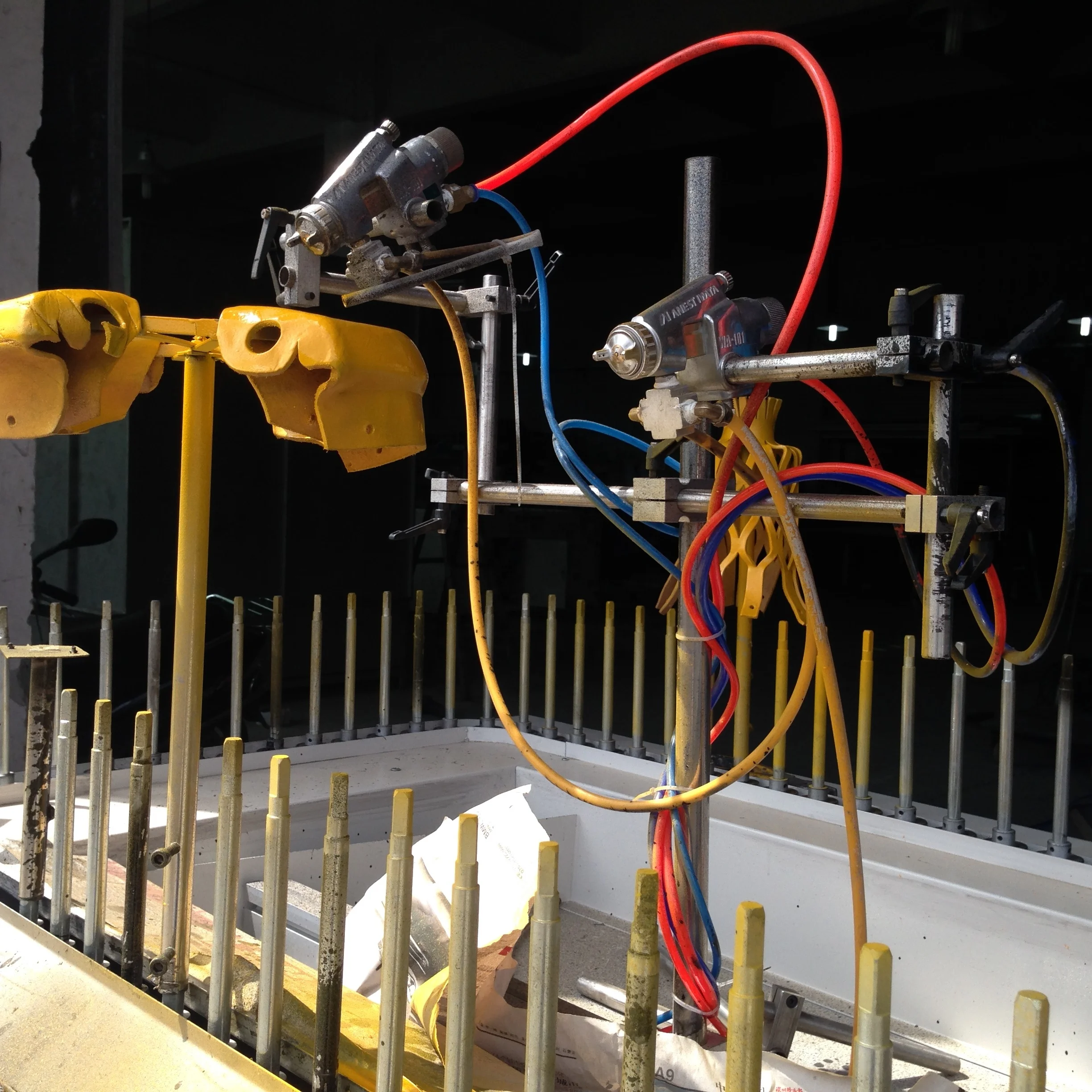

Automated Anodizing Hard Chrome Plating for Automotive Shafts and Piston Rods

Electroless nickel coatings are a popular anti-corrosion solution against salt and in harsh environments. They are used to protect the surfaces and extend the service life of crucial automotive components such as fuel systems, transmission parts, and engine components, which are affected by regular use and exposure to elevated temperatures.

In addition to electroless nickel plating, hard chrome anodizing is another popular surface treatment for crucial automotive parts such as shafts and piston rods. S&T Motiv, an automotive shock absorber manufacturer, uses our chrome plating line for surface treatment of piston rods.

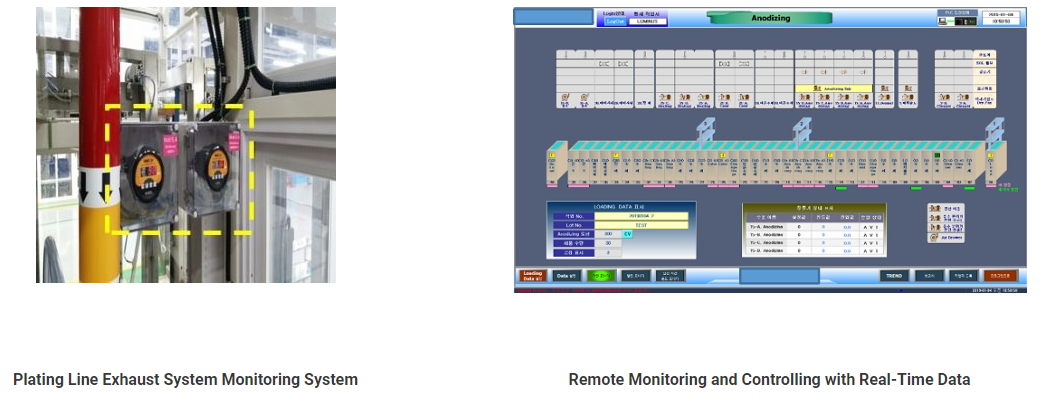

Our hard chrome anodizing line is built with 3 main priorities: safety, saving, and easy maintenance. The line is equipped with remote monitoring systems using sensors and programmed alarms, that can be easily integrated with your existing Manufacturing Execution Systems. They gather and analyze real-time data about temperature, dipping time, electric currents, recipes, motors and actuators, and pumps, filters, and exhaust systems. Any abnormality in these monitored items triggers the alarms. In order to minimize downtime due to the alarms, the operator’s HMI monitoring screen is integrated with a control system that analyzes the alarm history to prevent them and schedule maintenance in advance.

The filter housing is specially designed for easy maintenance using a combined residual sludge drain system with an Outlet-Inlet-Drain process. When the filter cartridge is being replaced the housing can be easily cleaned with water, which minimizes residual sludge and increases filtration efficiency.

At the bottom of our lines, we install leak sensors, with drip plates and leak detecting dikes underneath the entire line. We also offer the option of pull-type exhaust systems connected to the plating tanks, in addition to the push-type. These dual exhaust systems are monitored by digital sensors, which are installed by the enclosed

Spray paint machine -Nancy Xu:

which are installed by the enclosed door of the line. If the pressure falls below the setting point due to faulty exhaust systems, alarms are activated, and the door is shut with interlocks.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ