Years of

Experience

Sincerely welcome you to visit our company or contact us for cooperation!

Countries and regions around the world

Years of R&D

experience

Sets of machinery products

Installation on

clients

Company Machine has 20+ years of experience with providing wide area of specialty services works listed below.

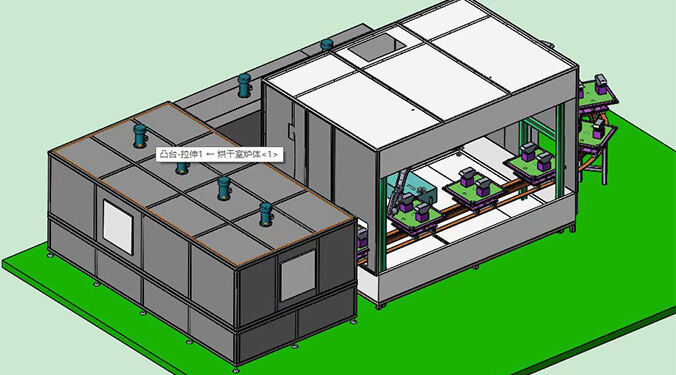

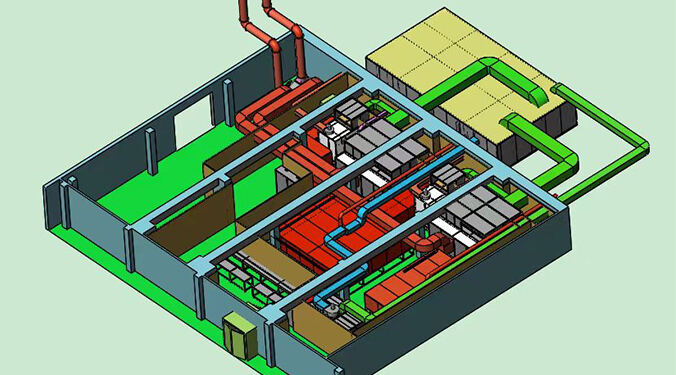

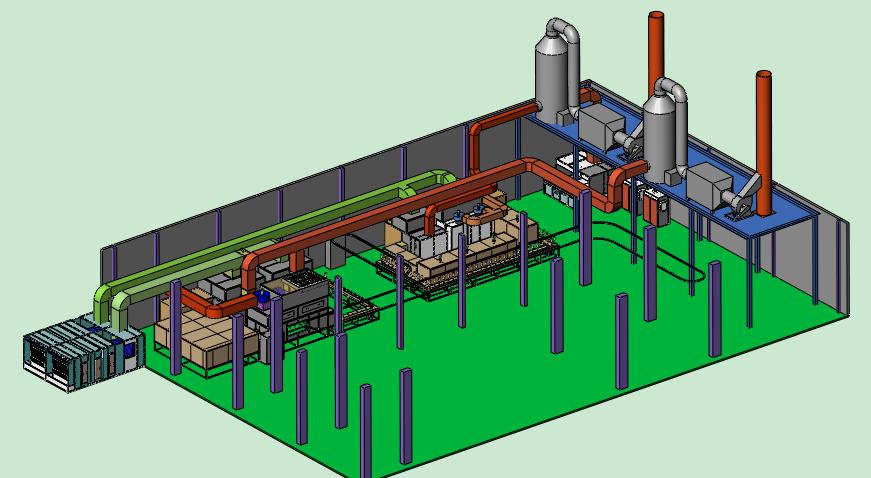

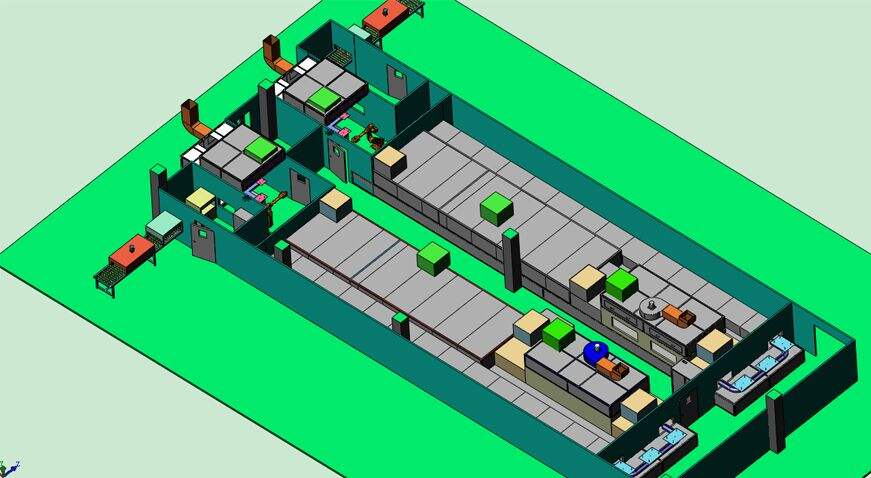

Auto spray paint line is widely used in the electric filed(cellphone shell,mouse shell,laptop shell etc),Comestic fileds(Comestic bottle,comestic cap,perfume bottle ),home sector(swiches socket,lamp shell,cookware etc),Car parts fields etc. It includes the dust-free workshop,Fresh air supply system,waster air treatment,Constant temperature and humidity system and UV Spraying and PVD Coating,Greatly improve the quality and efficiency of spraying.

Robot spraying is widely used in the automotive industry for spraying,bumpers,household appliances,refrigerators,washing machine casings,wooden furniture,irregularly shaped table legs,and other industrial fields such as aerospace and special equipment. The shape of the workpiece is complex and the size is variable. The robot adopts advanced motion control systems and sensor technology,which can achieve high-precision trajectory tracking and spraying thickness control. Meanwhile,its efficient and stable spraying process can effectively improve production efficiency,reduce labor costs,and bring more economic benefits to enterprises

Drying machine includes the industrial oven,tunnel furnace,they are widely used to drying the waterbased paint,solvent paint,screen printing fileds,water transfer fileds etc different coating fileds. The drying time and drying temperature can be customized according to the product’s paint.

UV Curing Furnace has the different type conveyor for different shape product using. It is mainly used to curing the UV paint,UV ink.the UV paint has scratch resistance,high drying efficiency,it can be cured instantly when exposed to UV light

The vacuum coating machine process uses evaporation,sputtering and other methods to emit particles of film material in a vacuum environment,which deposit on objects such as metal,glass,ceramics,semiconductors,and plastic parts to form a coating layer,achieving functions such as decoration,protection,anti fouling,moisture-proof,and extending the lifespan of objects. Vacuum evaporation coating mainly includes automotive reflective screens,handicrafts,jewelry,shoes and hats,clocks,lamps,decorations,mobile phones,DVDs,MP3,PDA shells,etc Industries such as buttons,cosmetic casings,toys,Christmas gifts,etc

The working principle of an automatic powder spraying line is actually a continuous process,which forms a uniform and firm coating on the surface of the workpiece through three stages: powder spraying,curing,and cooling. It has advantages such as automated operation,high efficiency,high quality,and energy conservation and environmental protection.It is widely used in the automotive industry,mechanical manufacturing,furniture and decoration,construction and building materials etc metal surface coatings.

Ultrasonic cleaning is the use of the cavitation,acceleration,and direct inflow effects of ultrasonic waves in liquids to directly and indirectly disperse,emulsify,and peel off the dirt layer,achieving the cleaning purpose. Ultrasonic cleaning is widely used in surface spraying,mechanical,electronic,medical,semiconductor,watch and jewelry,optical,and textile printing and dyeing industries

Xinqinfeng Specialized in the coating fields for 20+ years with countinuous process and development,Now Xinqinfeng machine is becoming the leading machine manufacturer and solution supplier in Coating fields.

We are a high-tech enterprise with various certifications and patents,and we have our own provincial R&D center.

We offer deep customization according to customer´s needs,providing one-stop solution from scratch and carrying out turnkey projects.

All of our machine offer one year warranty,Any broken parts,we will sent to the customer for free. Online technical support and Problem Solving

We will always provide immediate and 1 to 1 personal service during the whole lifecycle of the equipment. Once you have any problems,we will actively cooperate tohelp you solve them