A coating machine is a useful device that can be used to improve the form and function of multiple types. But let us not digress too much, and proceed to get a flash on the Swiss used coating machines as this particular write-up is structured around it...

There is a whole list of advantages that coating machines provide, which makes them almost an essential piece to have in several industries:

This means they can apply an assortment of substances such as paint, powder coatings, metals and adhesives / laminates with precision and efficiency.

Coating machines apply paint only where needed, which provides a more uniform and perfect finish for coated products.

These machines ensure that the coatings on products are long-lasting and durable, which offers tremendous quality to prolong its life.

Coating machines are able to produce excellent results, quickly and cheaply hence cutting the production cost of a certain product which makes them an effective approach by all means.

The scope of the coating machines industry is very wide because as an invention, it can be divided and subdivided to specific type within a certain market need or paper application (from boxboard level);

Film coating machines have been built such that they regularly carry out a thin layering to enhance the quality of pharmaceutical products primarily heart tablets and capsules based.

Nanocoater machines use the very best in nanotechnology to shield surfaces from rust and scratches so that they last as long as new products.

Water Paint machines use water based glass coatings that are environmentally friendly and provide an economical sustainability-based approach to your coating needs.

Ensuring a safe and hazard-free work environment is crucial when running the coating machines;

When handling the materials used for coating, protect yourself with gloves and safety goggles or masks.

The coating machine is operated in a well-ventilated environment, preventing the user from inhaling chemicals while ensuring air circulation.

It is highly dangerous and accidents do occur, so make sure you follow the instructions meticulously for safe working of the machine.

How To Master Coating Machine In Few Simple Steps

Operating a coating machine is an intricate process that involves the following steps to be executed efficiently:

The first step is to get the material you want coated ready for application.

Connect the machine to an air compressor in order for it to be able to work properly and allow the power supply as well.

Finely Intricate Machines Settings should be calibrated to make them apply the substance-coating being used properly.

You should test spray a small patch of the material to find out what quality you will get so that your final application is good.

Key Takeaway: The most important factor outweighing the use of a coating machine is that it must be properly serviced and maintained.

Ensure the proper installation of the machine for a better performance as well as life longevity.

This type of coating machine should be customer feedback and review oriented while choosing, this makes your Coating Machine Reliable one as it confirmed by our client availability.

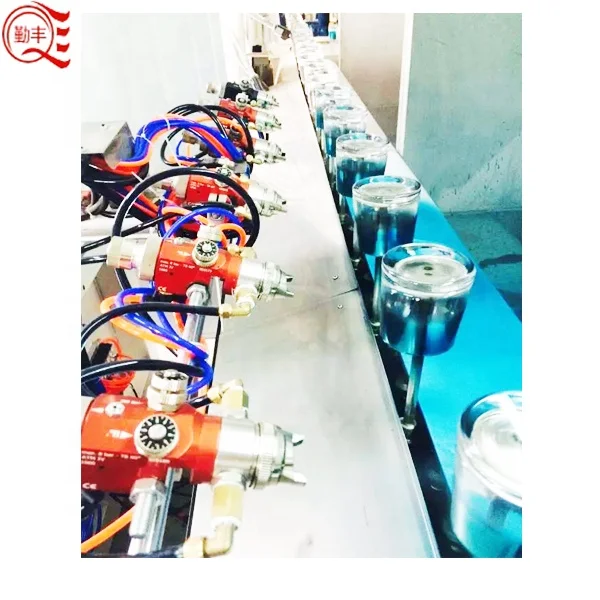

Xinqinfeng Specialized in the Auto Spray Paint Machine, full-auto spraying drying line,Industrial oven, UV Curing furnace PVD coating machine, Robot spraying paint line 20 years.machine been exported to many coating machine price,such as European,North America and South America, Middle East, West African other countries. Many machines have CE Certification.

Xinqinfeng specialized in AUTO Coating machine for 20 years. can offered the Non-customized service,one stop coating machine priceservice cleaning,spraying,drying,metallic coating,powder coating etc.From production installation,paint,paint teacher,air compressor ,can Provide key services to make customers more worry free achieve rapid mass production.

Xinqinfeng factory staffed by experienced engineers workers as we have 20 years of experience liquid spraying coating and powder coating. have a full line of coating machine pricefor nearly every kind product, from cosmetic bottles to car,from glass to wood, for paint UV paint, water-based, vanish etc.The years of experience allow us to design quick and production fast.

Xinqinfeng employs high-quality materials components for machine. First class metal parts, imported spraying paint guns, top electronic brands, Taiwan brand PLC etc.We have seasoned workers coating machine priceensure that each process is designed to be most efficient, right from conception production.Xinqinfeng has good reputation in customers,nowadays,90% of customers are from overseas.