However, the users will get nothing in hand if they do not take care of their spray coating machines all over this doing.

Spray coating machines are unique tools that provide a smoother distribution of material over surfaces. These machines can operate on a large variety of surfaces such as metal, wood plastic etc. They beat old methods in several dimensions:

Coating is the Same Everywhere: Spray coating machines ensure that all portions of a surface receive an even coat. It can prevent surfaces from being damaged.

Quick Performance: They are faster than the conventional methods and save time. Due to the massive surfaces these devices can handle quickly, we are empowered with the ability to get more achieved.

A Fix to Waste: The spray coating machines are not waste oriented for the paint. They only spray where it is necessary to save on fuel.

The Spray coating machines have evolved over the years. Some deliver the spray with air, some use a motor to disperse tiny droplets. Each has its pros and cons, one being more suitable than the other for the job.

It is very important to be safe when using the spray coating machine. They are equipped with things that make people safer, such as

Safety Locks: It prevents the machine from going.

Non-combustible: The machines have fire detective and stopwatch features that prevent a spark from catching the pile on fire.

Unpolluted air: The machines have filters so workers can breathe in good stuff, not bad.

Spraying with spray coating machine is a fairly simple, but still requires proper attention to ensure quality results.

First and foremost one should clean the surface before starting

Coating Addition: The composition is output at a predetermined temperature of the coating material.

Set It Up - How The Machine Sprays the Coating

Apply the coating: Begin spraying the layer again equally over your surface.

After applying first coat let it dry; so you may add more layers.

Maintaining a Spraying Coating Machine A spraying coat machine has to be kept in good working order and doing this involves some regular maintenance such as keeping the parts cleaned and fixing them when necessary. You will need to replace the HTC One M9 speaker, and its repairability depends on using high quality parts.

Ways of using these machines:-

Automobiles: They do the painting and increase cars.

This coating is for two types of buildings, they apply only one layer;

Furniture refinishing: Refinsher process gives it a new life, making it look beautiful while giving you that carried over finish with sustainability for longevity.

In the business and industrial sectors, engine coating solutions are built in spray coating machines. The machines provide a host of benefits over traditional coating techniques, transforming the way coatings are applied to surfaces [1].

The main benefit of spray painting machines is that they provide even cover on a surface, protecting it fully from damage and rusting. Furthermore, these machines are also very swift and fast as they can efficiently cover a large surface in less time which add to the efficiency of productivity. Additionally, spray coating systems ensure that only a selected quantity of material is sprayed while minimizing waste and saving on resources.

Spray Coating Machines with Innovative Designs

Spray coating machines have also advanced through mechanical or pneumatic innovations over time. Pneumatic machines use compressed air to propel materials onto surfaces while mechanical sprayers have rotary atomizers for producing fine droplets. The kind of designs used will depend on the need from job to another.

Safety measures in the operation of spray coating machines are crucial, and these Machines come with several forms of safety to protect individuals. Safety interlocks to prevent operation in unsafe conditions, explosion-proof electrical components for reduced fire hazards and air filters for maintaining clean air quality during the spraying process.

Spray Coating Machine Use Guidelines

Spraying coating machine is very simple to operate, but the details are important. The steps include preparation of surface, maintaining the coat material at proper temperature and viscosity, adjustment for spray pattern and flow rate settings, uniform application to wet mill thicknesses plus about 30% more immediately after spraying another layer whilst first layer is still tacky; and allowing the undercoat to dry thoroughly before adding future layers.

Preventive maintenance is very important for ensuring that the spray coating machines give their best performance. Firstly, it means cleaning, lubricating and only swapping out parts when they are in need of replacement - and considering carefully the quality of those new components for repairs. In purchasing of a spray coating machine, however, the type and quality of manufacturer who supplies you with these equipment directly determines whether what comes into your shop are only top-of-the-line products (including warranties which gives peace of mind) and full technical support to ensure that these machines run properly after decades from manufacture.

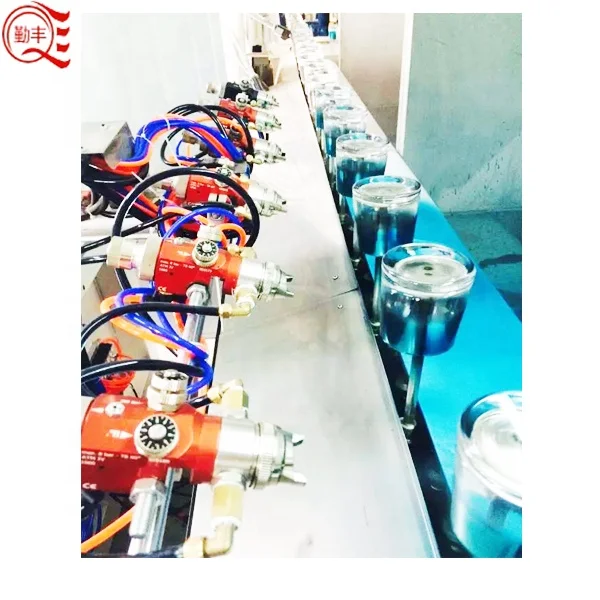

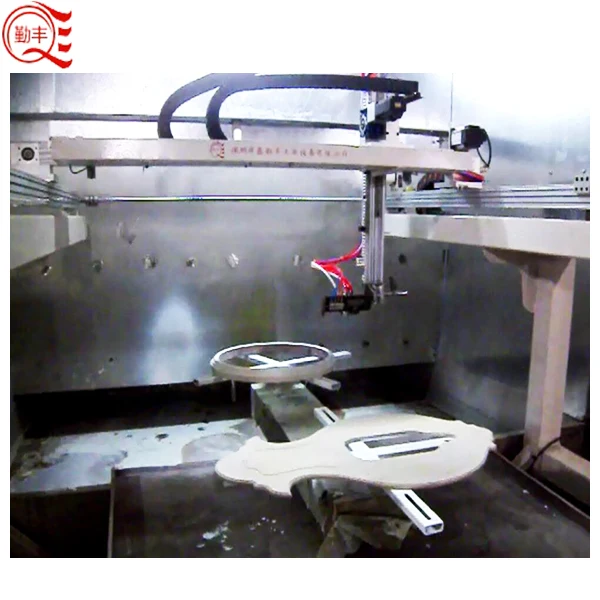

Xinqinfeng Factory staffed by skilled spray coating machineemployees 20 years of experience in liquid coating and powder coating. have full ranges of equipment for all types products, from wood to glass, to cosmetic bottles all other things. For paint water based paints, vanish, UV paints, and more.

Xinqinfeng uses high-quality materials parts to make machine. These include top of line metal components, imported spraying spray coating machineguns made from Taiwan, best electronic brands as well as Taiwan company PLC.Our engineers and workers have experience to ensure that each step is ideal solution.Xinqinfeng has a good reputation in customers,nowadays,90% of our customers are from overseas.

Xinqinfeng has been specialized in AUTO Coating machine more than 20 years. We can offered the Non-customized service,one stop coating service cleaning,spraying,drying,metallic coating,powder coating etc.From production installation,paint,spray coating machineteacher,air compressor ,can Provide key services make customers more worry free achieve rapid mass production.

Xinqinfeng specialized the auto spray paint machine, full-auto spraying drying line,Industrial oven, UV Curing furnace and PVD coating spray coating machine,Robot spraying paint line twenty years.Our machine has exported numerous countries, including North America, European, South America,Middle East, West African and other countries. Many machines have CE Certification.