Aperçu

Demande d'information

Produits connexes

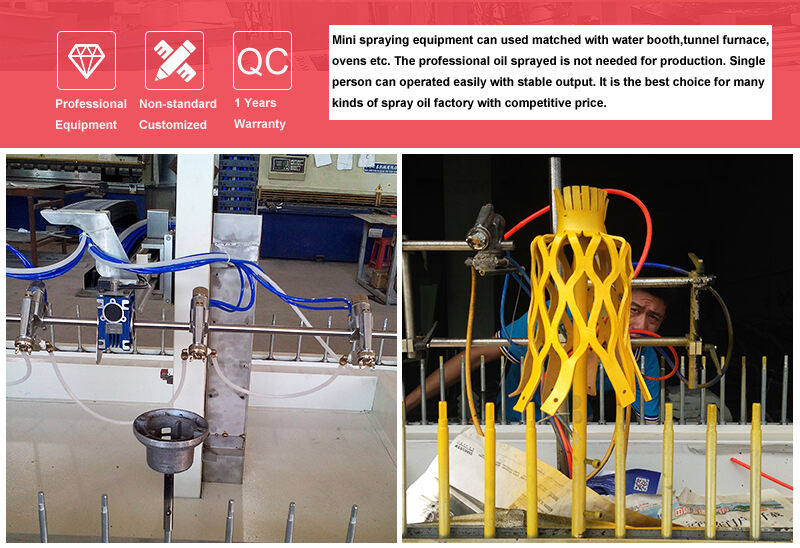

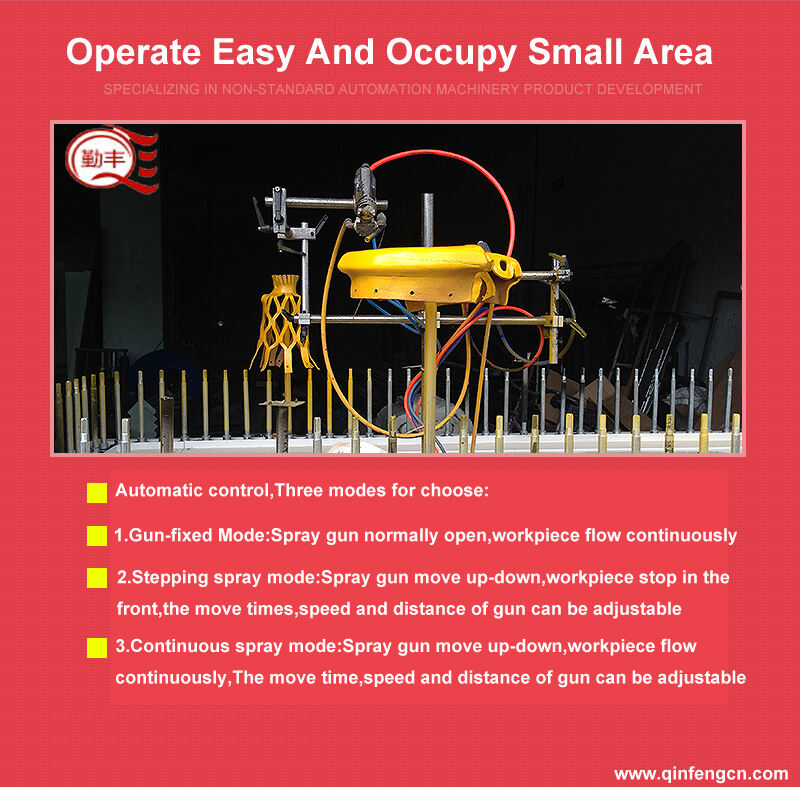

Opération facile et simple, une seule personne peut la manipuler

Type mini, occupe peu d'espace

Pulvérisation automatique, haute efficacité, Réduit les coûts de main-d'œuvre

Prix usine, Prix compétitif

Haute qualité, Garantie d'un an

Marque : Xinqinfeng

Présentation de la Ligne de Peinture UV Automatique pour Flacons Cosmétiques par Xinqinfeng, votre solution tout-en-un pour le sablage qui répond certainement aux exigences cosmétiques.

Cette méthode est construite avec une technologie révolutionnaire et de pointe qui offre un motif de pulvérisation précis et constant sur les contenants esthétiques. La ligne automatique de peinture UV est conçue pour répondre aux exigences rigoureuses de l'industrie cosmétique. Sa construction de haute qualité garantit qu'elle peut résister aux conditions de travail les plus sévères, offrant une performance supérieure tout en maintenant une précision maximale et une exactitude.

La ligne de peinture automatique Xinqinfeng avec pulvérisation UV pour flacons cosmétiques est simple à installer et facile à régler. Avec son logiciel convivial, il suffit d'appuyer sur un interrupteur pour démarrer le processus de pulvérisation. Cela signifie que vous pouvez commencer à l'utiliser dès sa sortie d'emballage, éliminant ainsi la nécessité d'avoir un professionnel pour superviser le fonctionnement et l'installation.

Le système automatisé de la ligne de peinture garantit également un minimum d'erreurs humaines, ce qui permet d'obtenir des résultats de haute qualité à chaque fois. L'efficacité et la précision de l'unité sont rendues possibles grâce à une technologie de pointe qui assure une perfection dans la pulvérisation, quel que soit le volume du lot.

La ligne de peinture UV automatique pour bouteilles cosmétiques par Xinqinfeng est conçue pour répondre aux divers besoins de l'industrie des cosmétiques. Les produits peuvent être configurés et personnalisés pour répondre à vos besoins spécifiques, que vous ayez besoin d'une production à petite ou grande échelle. Cette flexibilité garantit que quelles que soient les exigences de votre atelier, Xinqinfeng a une solution pour vous.

De plus, la ligne de peinture utilise une peinture UV de haute qualité qui est écologique et réduit les déchets. Contrairement à la peinture traditionnelle, il n'y a pas d'émission de substances volatiles organiques, connues pour contribuer à la pollution de l'environnement. L'utilisation de la peinture UV signifie également que le processus de séchage est plus rapide et plus économe en énergie, réduisant ainsi vos coûts de fonctionnement.

Caractéristiques de production :

Spécification du produit :

Non. |

Article |

Spécification |

1 |

Les dimensions extérieures du rack |

Les dimensions : L2900mm x P1100mm x H850mm (1 ensemble) |

2 |

Le rack |

Le rack est fabriqué à partir de sections carrées soudées en 50#. La base du rack est équipée de roulettes et d'une tasse de pied. La hauteur est ajustable. Le rack est scellé par une plaque. ,La structure est compacte et généreuse. |

3 |

La chaîne de convoyage |

La chaîne de convoyage utilise une chaîne spéciale pour ligne automatique. La course est de 50,8 mm, la longueur totale est de 6,4 m. Chaque distance de deux courses utilise un dispositif spécial pour le produit. |

4 |

Le Moteur |

Le moteur utilise un réducteur d'engrenage de 0,5 HP importé de Taïwan pour la transmission. La vitesse de la chaîne est ajustée en adoptant un convertisseur de fréquence ZONCN de 1 HP. La vitesse de la chaîne est ajustable entre 0,1 m/min et 5 m/min. Le contrôle de la vitesse du moteur par fréquence est économiseur d'énergie. |

5 |

Le Système de Rotation par Frottement |

Il dispose de deux ensembles de systèmes de frottement spéciaux, le moteur adopte un moteur électronique de 200 W à régulation de vitesse. Il peut tourner dans les deux sens. |

6 |

Le Contrôle Électronique |

Le contrôle électronique utilise principalement la marque CHINT, célèbre en Chine. L'indicateur lumineux, l'interrupteur, le relais et les contacts sont équipés d'une protection contre surcharge. Les composants du contrôle électronique sont placés sous les étagères. |

7 |

Le Traitement de Surface |

Revêtement en poudre électrostatique blanche ordinateur |

8 |

Système de Peinture et d'Approvisionnement en Huile |

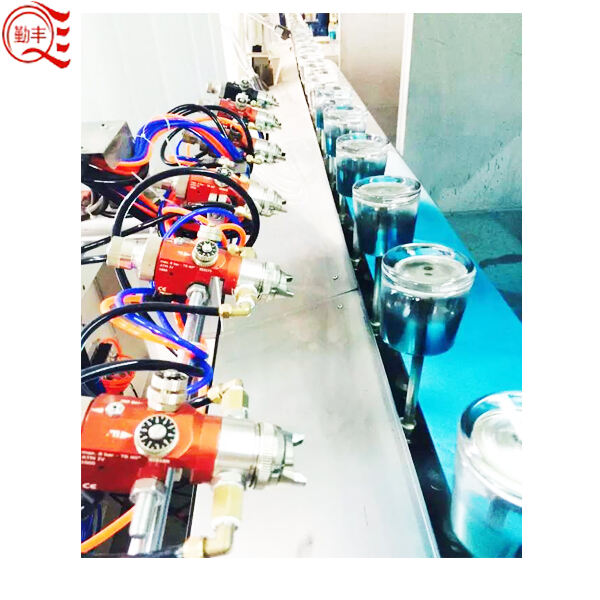

1. Le pistolet à peinture automatique utilise un pistolet à peinture automatique ANEST IWATA WA-101 du Japon. Le diamètre est de 1,0 mm. La quantité de pistolets est de six. Un ensemble de supports ajustables est équipé. 2. Deux ensembles de pompes à diaphragme à trisection sont équipés. 3. Il est équipé de tuyaux d'huile relatifs, de tuyaux d'air, de vannes de régulation de pression, de séparateur d'huile et d'eau, ainsi que d'une série de vannes électromagnétiques. |

Images du produit :

Application :

La mini machine de pulvérisation automatique ou la ligne de peinture par pulvérisation automatique mini est largement utilisée dans le domaine du plastique, du métal, de l'acier inoxydable, du verre, du bois, etc., pour la pulvérisation des surfaces de formes rondes, cylindriques, coniques ou autres formes irrégulières et de petite taille, telles que les coques de téléphones portables, les verres, les lampes, les casques, les bouteilles, les supports, les couvercles de cosmétiques, etc.

FAQ

Question 1 : Je ne sais rien sur la machine. Fournirez-vous un support technique ?

Répondre bien sûr. Chaque machine sera testée avant livraison. Nous nous assurerons qu'il n'y a aucun problème avec la machine lorsqu'elle quitte notre usine.

Lorsque l'équipement est petit et standard, comme les équipements de pulvérisation à cinq axes, les petites lignes de pulvérisation, les fours tunnels ou les fours compacts, les cabines de pulvérisation, les fours de cuisson, etc., nous pouvons envoyer un manuel utilisateur détaillé et des vidéos pour

vous aider à installer et à exploiter l'équipement. Bien entendu, Vous pouvez organiser l'envoi de 2 à 3 travailleurs qualifiés pour venir dans notre usine apprendre à manipuler la machine.

Si la machine est une ligne de pulvérisation et de grande taille, Lorsque la machine arrivera dans votre usine, nous enverrons des experts pour vous aider à l'installation et à la mise en service. Une formation à l'opération sera fournie. Des conseils sur l'entretien seront donnés ainsi que des pièces de rechange suffisantes. fournis.

De plus, nous offrons un service de conseil pour créer les installations appropriées pour faire fonctionner la machine.

Question 2 : Quel est le prix de la machine ?

Répondre : Généralement, la plupart des machines sont personnalisées pour nos clients. Si vous avez des dessins ou des informations sur les spécifications de la machine, veuillez nous les envoyer pour obtenir un devis.

Si vous êtes totalement nouveau dans ce domaine, veuillez nous envoyer les détails concernant votre pièce comme suit :

1. La taille maximale de la pièce :

2. Le poids maximal de la pièce :

3. La production par mois / par jour :

4. Chauffage Température et temps (Si vous avez besoin de l'équipement de séchage) :

5. Changement de couleur (Combien de couleurs ? Combien de temps faut-il pour changer les autres couleurs ?)

6. Processus de pulvérisation (Quelle peinture allez-vous utiliser ? Combien de fois pulvériserez-vous ?)

7. Les dimensions de l'atelier pour l'équipement :

8. Il est nécessaire d'avoir des photos de pièces à travailler :

9. L'alimentation : tension triphasée industrielle

10. Autres exigences du client :

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ