개요

문의

관련 상품

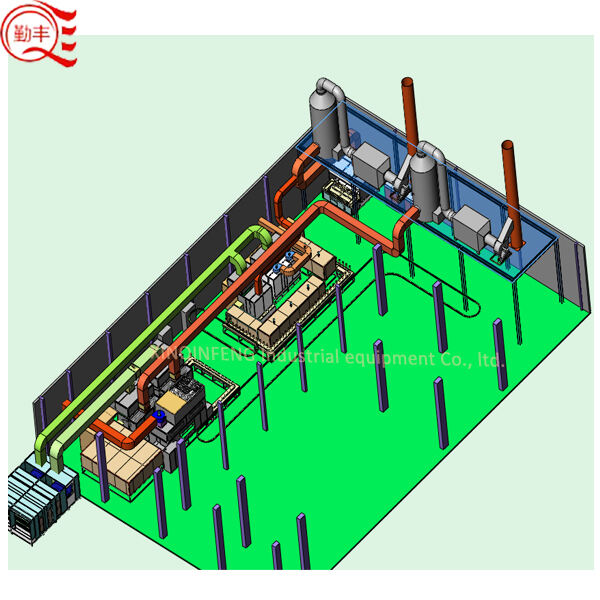

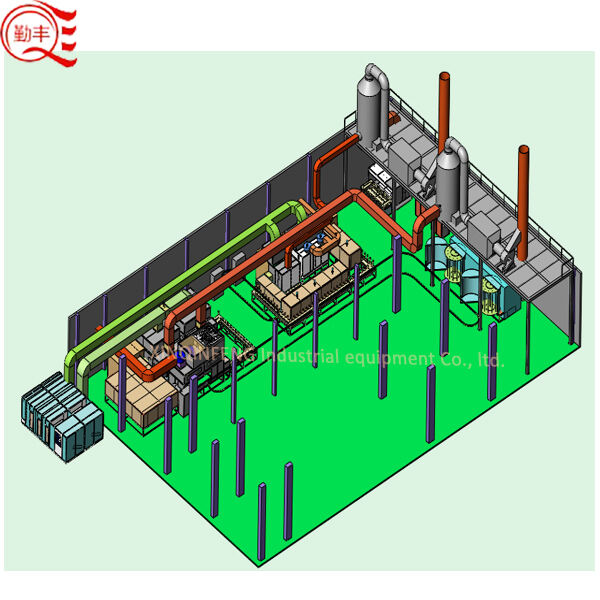

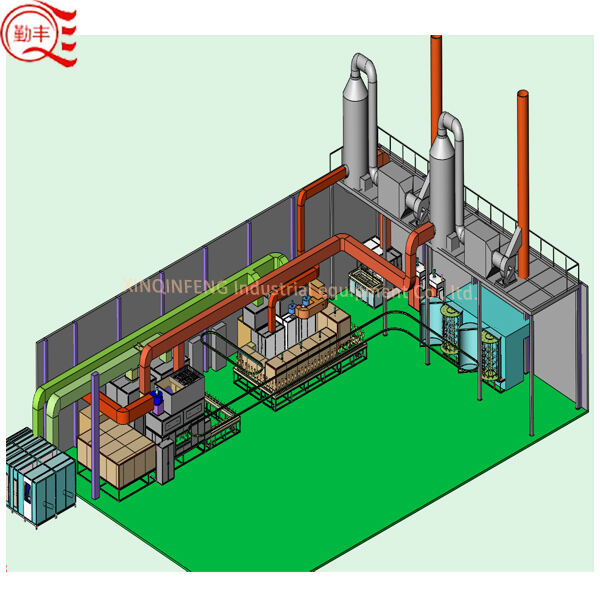

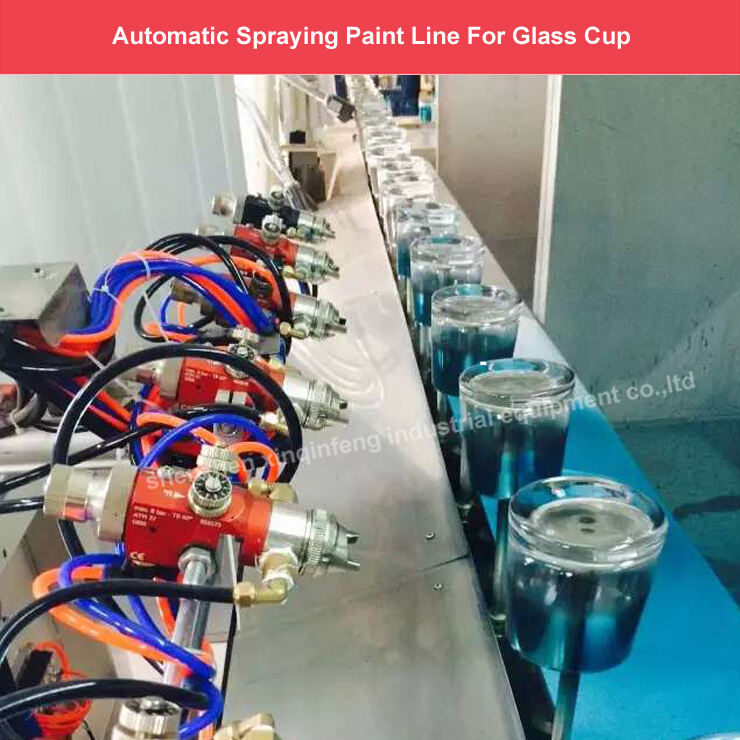

- 자동 스프레이 페인트 라인에는 자동 먼지 제거, 자동 스프레이 페인팅, 자동 건조 및 자동 냉각 기능이 포함되어 있어 노동력과 비용을 절감하고 효율성을 향상시킵니다.

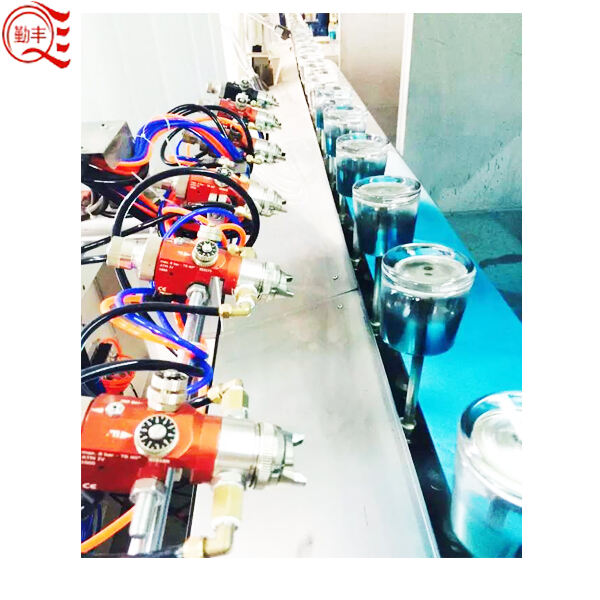

- 균일하게 분사하며, 정확도가 높아 실행 정밀도는 0.2mm 내외입니다. 분사 정확도는 0.2-1mm 범위 내입니다.

- 유연한 분사 크기는 페인트를 20% 절약할 수 있습니다.

- 효율성이 높아 연속 작업이 24시간 가능하며, 생산량은 수작업보다 3-5배 많습니다.

- 완전한 시각 터치 스크린 제어, 쉽게 작동 가능하며 데이터를 빠르게 저장하고 읽을 수 있음

- 분무 디버깅은 10분 이내에 간단하며, 프로그램은 쉽게 조작 가능

- 전 공장 플라스틱 부품 자동 먼지 코팅 장비

- 전 공장 금속 제품 전기泳도장 장비

- 전 공장 가구 전기泳도장 장비

- 전 공장 기관차, 오토바이 도장 장비

- 조작기, S 기도 중 로봇 등 산업용 로봇 장비

- 자동 자외선 경화로 라인

- 완전 자동 정전기 먼지 제거 장비

- DISK 자동 정전 도장 장비

- 다양한 종류의 건조, 실크스크린 장비

- 다양한 종류의 PVC/SUS 벨트, 나일론 컨베이어 장비

- 테플론/세라믹 분말/PE 침강 고온 장비

- 다양한 종류의 수막 부스 등 장비

- 고수준 공급 시스템

- 폐수/폐가스 재활용 시스템

- 전 공장 전도 도금 코팅 장비

- 전 공장 전기泳 코팅 장비

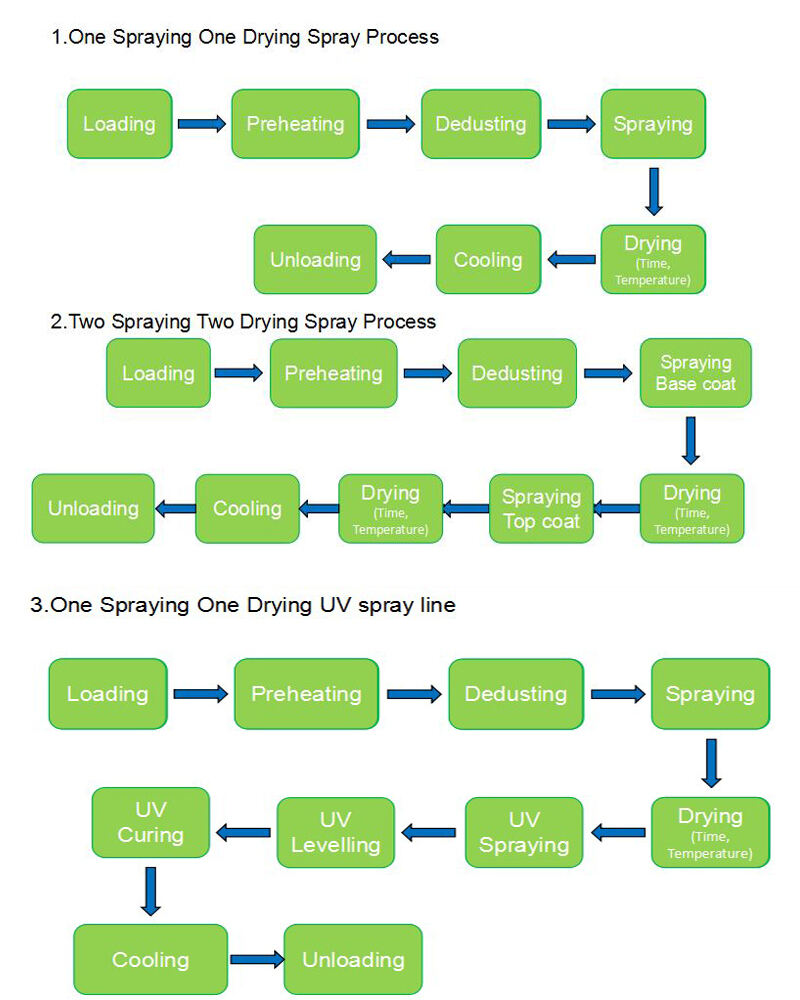

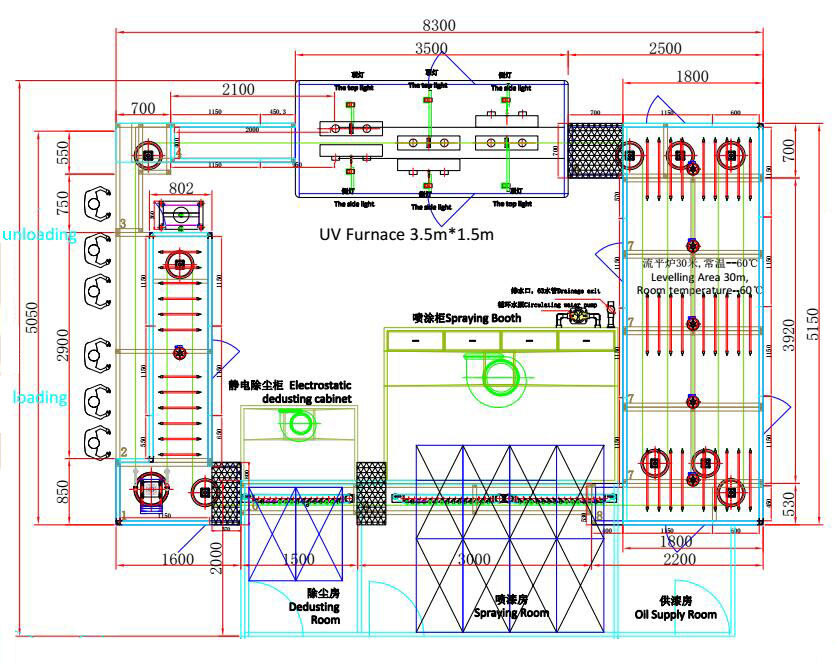

플라스틱 부품용 자동 스프레이 도장 라인 및 UV 경화 건조 코팅 라인

| 생산 기능: |

| 제품 사진: |

| 용도: |

자동 분무 도장 라인은 높은 효율과 높은 생산성을 달성할 수 있는 제품에 널리 사용됨

다양한 종류의 병, 와인병, 화장품 병, 화장품 뚜껑, 유리컵, 유리 구슬, 금속, 플라스틱 등

원형 디스크, 주방용품, 헬멧, 후진경 등 불규칙한 형태의 제품

심천 X inqinfeng 인더스트리얼 이큅비PMENT co., LTD . w 2004년에 설립되었습니다. 제품은 다양한 지역들 중국 본토와 외국에서부터 시작하여 발전을 거듭하며 부서는 신신풍이 되다 a 전문 제조업체들입니다 어떤 현재 비표준 자동화 장비를 전문으로 하며 c 기계 장비 ’s 개발, 설계 및 생산 ,표준 대형 공장과 선진적인 생산 장비를 갖추고 있습니다. 수년간의 끊임없는 노력과 축적 후 , 이제 신친펑은 전문적으로 규모와 실력이 있는 산업 자동화 장비를 다루고 있습니다.

주요 제품 포함하다 산업 표면 자동 도장, 자동 건조 및 전체 공장 자동 분무 계획 , 디자인 중 제조 및 산업용 로봇, 자동화 장비 및 기타 비표준 테스트 장비

주요 제품:

우리의 서비스

사전 판매:

1. 전문적인 조언을 제공하고 고객에게 최고의 솔루션을 제공합니다

2. 고객의 요구 사항에 따라 우리의 엔지니어는 귀하를 위해 도면과 솔루션을 제공할 것입니다.

3. 우리는 고객의 솔루션에 따라 경쟁력 있는 가격을 제공합니다

사후 지원:

1. 우리는 현장 설치, 가동 및 운영 교육을 위해 엔지니어를 보냅니다.

2. 우리는 고장 처리 서비스와 평생 보증을 제공합니다.

3. 우리는 각 기계에 대해 1년 보증을 제공합니다.

4. 우리는 주기적으로 당신에게 연락하여 기계의 상태를 확인할 것입니다.

5. 우리는 또한 귀하의 기존 기계에 대한 추가 연장을 위한 서비스도 제공합니다.

만약 하루 생산량과 제품 크기에 대한 정보와 함께 제품 사진을 보내주실 수 있다면 첫 번째 참고 자료로 사용하겠습니다. 정보를 받대로 soonest, 우리는 보낼 것입니다 가격이 포함된 솔루션을 가능한 빨리 보내주시고, 지원에 감사드립니다!!!

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ