Apžvalga

Užklausa

Susijusios produktai

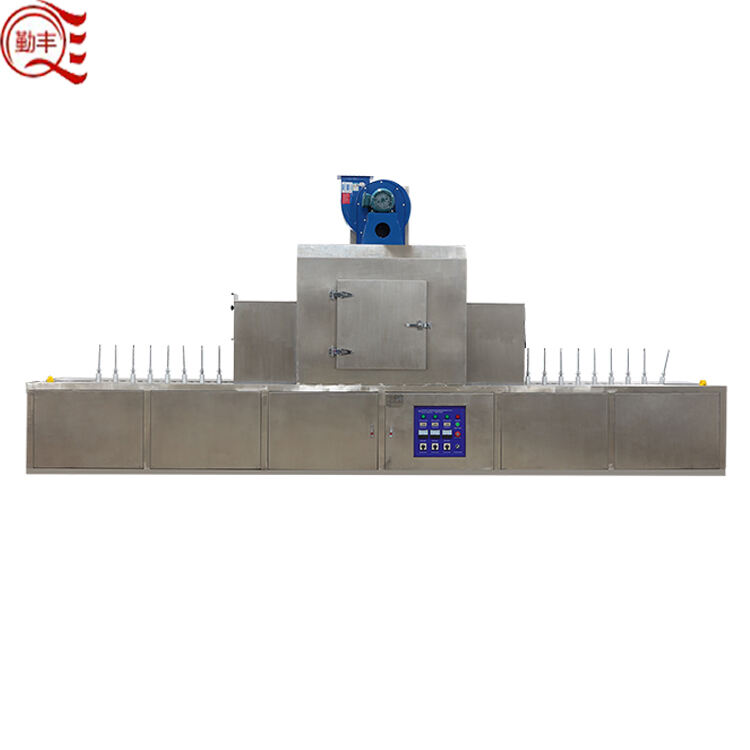

Pateikiamas Xinqinfeng kurojimo krosnis popieriaus spalvoms – idealus atsakas visiems jūsų popieriaus spalvavimo poreikiams. Jei ieškote aukštos kokybės ir patikimos kurojimo eilutės, neeilinkite toliau nei Xinqinfeng.

Šis šiluminis kaminas suklastymui yra sukurtas, kad užtikrintų greitą ir išsamų suklastymą su porceliano aukščiu, užtikrinant tvirtą ir ilgai trunkančią pavidalį jūsų daiktams. Arba apie didelius ar mažus mastelius, tai tikrai mažas, mūsų šiluminiame kampane yra įrengta spręsti bet kokio dydžio darbus dėl jo erdviojo vidaus ir tikslaus temperatūros.

Viena iš pagrindinių pasirinkimų, kurie priskiriami Xinqinfeng šiluminiame kampane suklastymui su porceliano aukščiu, yra jų energijos efektyvumas. Ši linija gali teikti nuolatinį šilumą per visą suklastymo procesą naudojant minimalią energiją kartu su aukštesniu lygiu vamzdinimo. Tai ne tik užtikrina jums pinigų taupymą savo energijos sąskaitose, bet taip pat sumažina jūsų aplinkosaugos poveikį - abiejų pusų laimėjimas.

Kita Xinqinfeng poravimo šiltnamio naudingesnysis pusė yra jo paprastumas naudoti. Vartotojui draugiškas valdymas leidžia lengvai reguliuoti temperatūrą, laiką ir kitus nustatymus, kad užtikrinti optimalias poravimo rezultatus. Produkto eilė taip pat turi automatinį išjungimą, todėl galite ramiai miegoti, žinodami, kad jūsų produktai poroja saugiai ir efektyviai.

Nepalikome nieko atsitiktinai, užtikrinant aukščiausios kokybės medžiagas ir darbą statydami Xinqinfeng poravimo šiltnamį poravimui su pudriniu. Išorė yra pagaminta iš galingo metalo ir turi stilingą ir šiuolaikinį dizainą, kuris prisiderins prie bet kokio darbo vietos. Tuo tarpu, viduje yra apversta iš trunkaus ir šilumos atsparaus medžiagos, kuris išlaikys net sunkiausių poravimo sąlygų.

Šiluminis Xinqinfeng džiovintuvas pavidaliniam džiovavimui yra įrankis, kuris yra būtinas gausiant glodžius, be defektų paviršius produktams, nepaisant, ar esate patyręs profesionalas ar tiesiog pradedate plačioje pavidalinio džiovavimo srityje. Jis yra patikimas, veiksmingas ir lengvas naudojimui, be to jis pardavinamas su papildoma ramybės manykle kaip produkto, susijusio su pasitikinama prekių ženklu Xinqinfeng.

A. Momentinis sausinimas; išvengiate sausinimo laukimo laiko, drastiškai sumažinant džiovavimo procesą.

B. Galima tiesiogiai prisijungti prie džiovavimo mašinos. Mašina gali būti prisijungta prie bubeno ar cortyninio tipo džiovavimo mašinos. Po džiovavimo gaminys tiesiogiai yra sausiavimas, pašalinant rūpesčius dėl apdorojimo.

C. Džiovavimo paviršiaus tvirtumas padidėja, spalva yra ryškesnė.

D. Platus sausinimo funkcijų spektras: mediena, plyta, baldai, plienas, statybiniai medžiagai, lęšiai, odos ir kitų UV džiovavimo po sausinimo.

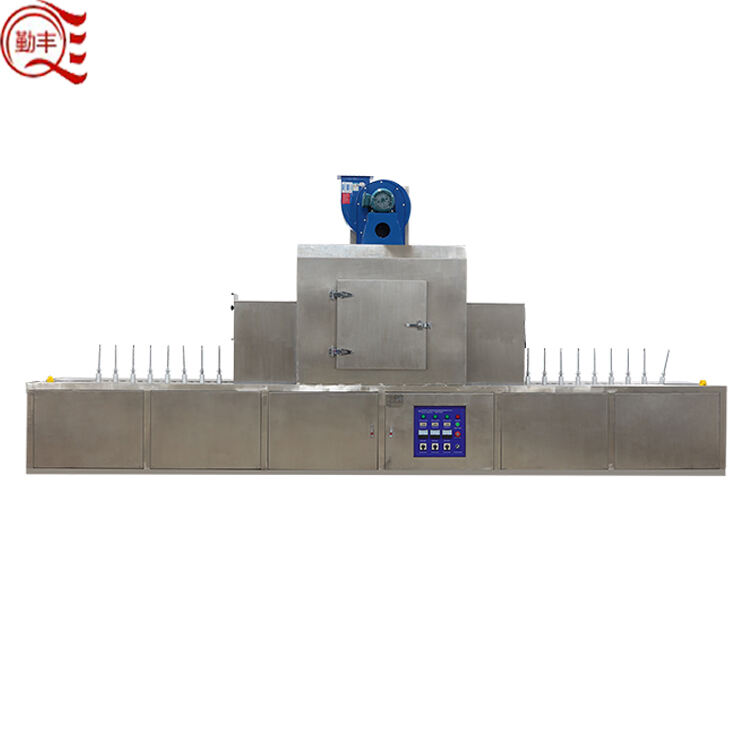

Produkto specifikacija:

|

Ne, aš ne. |

Prekė |

Specifikacija |

|

A |

Dydis |

Dydis :L 2500 × W 690 (veiksmingas plotis) x H 800mm (Kiekis: 1vnt ) |

|

1 |

Stabai |

Korpusas ir įrenginio pėda yra pagaminti iš suvaržytos plieno dėžutės. Pėda yra equipped with M14 reguliuojama pėdos čiaurka. Jis taip pat yra apdarytas varikliu. |

|

2 |

Kepurio juosta |

Jūros juostos aukštis nuo žemės yra 0,8 metrų. Plieno tinklo juostos plotis yra 690 mm, o juostos apskritimo ilgis yra 5 metrų. Degimo zonos ilgis yra 500 mm, o veiksmingas aukštis yra 250 mm, kuris yra reguliuojamas. |

|

3 |

Variklis |

Variklis naudoja 60W elektroninį greičio reguliavimo variklį. Juostos greitis yra reguliuojamas. Taivanas ZONCN dažnių keitiklis. 1-6m/min, energijos taupymas. |

|

4 |

Paviršiaus apdorojimas |

Kompiuterinis baltais elektrostatinis porceliano uždengimas, atsparus smūgiams ir šramoms. |

|

B |

Šiltinio danga |

Šiluminių sričių dydis yra L1200mm× W700mm ×H550mm. |

|

1 |

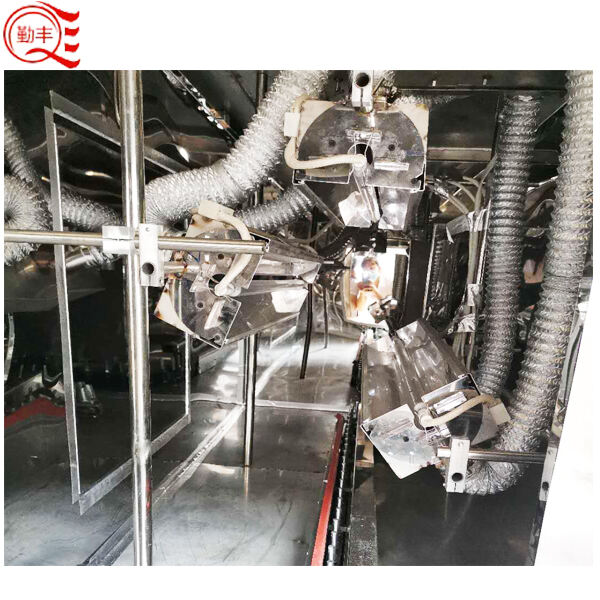

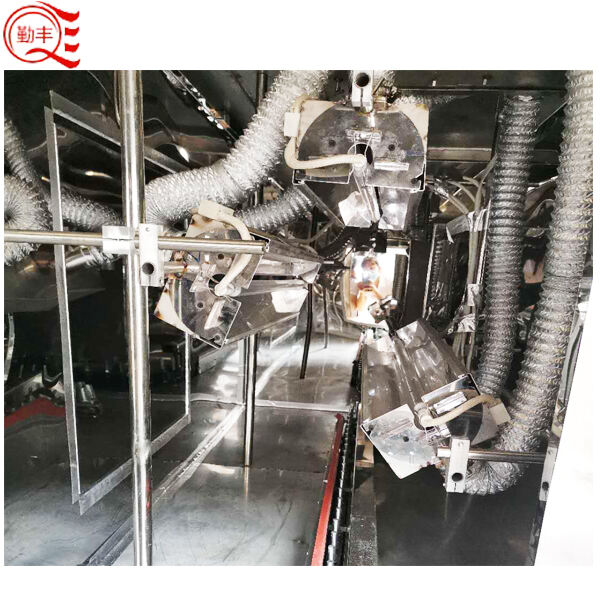

Uv lempa |

Jis naudoja 3 gabalius 3KW UV šviesoforius kartu su transformatoriumi ir kondensatoriumi. Kiekviename šviesofore yra trys pasirinkimai: stiprus, vidutinis, silpnas. Šviesoforiai naudoja Pekino jodinę dėžutę kartu su reflektoriumi, dėžute ir sukamos. |

|

2 |

Vėjo variklis |

Jis naudoja vieną profesionalų 1.1KW 380V, 1400R/min aukštos greičio centrifuginių ventilatorių rinkinį. Oro srautas yra 1200m3 valandos. 1 rinkinys. Viduje įrengtas išėjimo dūmenų potvynis, kuris gali sumažinti produkto ir krosnies vidinę temperatūrą, taip pat pagerinti švieslentų tarnavimo laiką. |

|

3 |

Elektroninis valdiklis |

UV švieslentių transformatorius yra apgabentas energijos saugojimo kondensatoriumi. Kiekvienai UV švieslentai priskirtas laiko skaičiuoklė naudojimui įrašyti. Temperatūros reguliatorius naudoja Taivano Berme skaitmeninį rodymo temperatūros reguliatorių. |

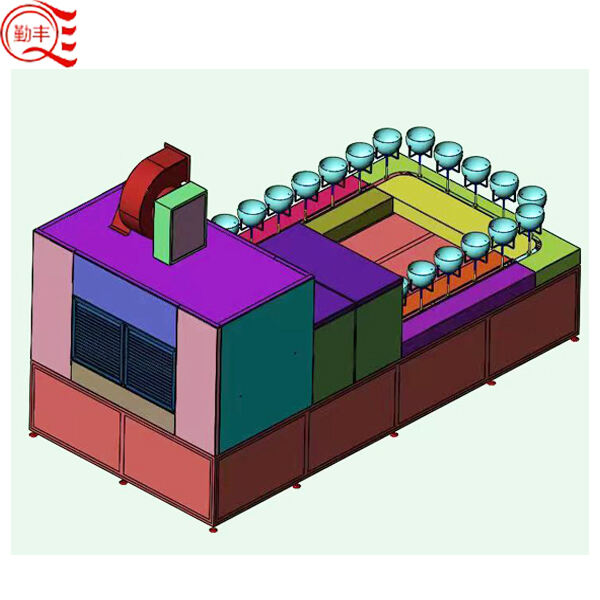

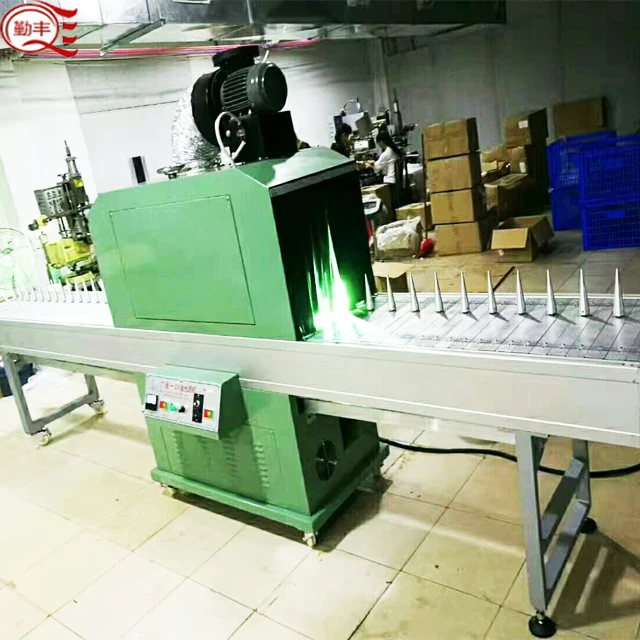

Produkto Nuotraukos:

Taikymas:

UV sukimosi technologija jau plačiai yra pripažinta daugelyje pramoninių sričių, įskaitant automobilių, telekomunikacijų, elektronikos, grafinės menininės, konvertavimo bei metalo, stiklo ir plastmasės dekoravimo sritis.

DAK

Klausimas 1: Aš nieko nežinau apie mašiną. Ar suteiksit techninę paramą?

Atsakymas : Tokiu atveju. Kiekviena mašina bus išbandyta prieš pristatymą. Įsitikinsime, kad mašinoje nėra problemų, kai ji palieka mūsų gamyklą.

Kai įranga yra nedidelė ir standartinė, mes galime išsiųsti detalų vartotojo vadovą ir vaizdo pavyzdžius, jums įrengti ir valdyti įrangą. Be abejonės, Galite išdėstyti 2-3 protingus darbuotojus, kad jie atvyktų į mūsų gamyklą ir išmoktų, kaip valdyti šią mašiną.

Jeigu mašina yra labai didelė ir ilga, Kai mašina bus pristatyta į jūsų gamyklos, mes siųsime ekspertus, kurie padės jums su montavimu ir paleidimu. Bus suteikiama operacijų mokymo programa. Bus pateikiami priežiūros patarimai ir pakankamai varomųjų dalių. bus pateikiami.

Be to, mes teikime konsultacinę paslaugą dėl tinkamų įrenginių sukūrimo, skirtų mašinos veikimui.

Klausimas 2: Kas yra UV šlapinimas? ?

Atsakymas :Ultravioletinė šviesos kūrimas (dažniausiai vadinamas UV kūrimu) yra fotocheminis procesas, kuriame naudojama didesnio jaudingo ultravioletinė šviesa, kad iškirstų arba „susirūtintų“ tinta, aukščiai ar lipdžius. Palyginti su tradiciniais susidrying metodais, UV kūrimas suteikia daug privalumų, įrodydamas, kad jis padidina gamybos greitį, mažina atmetimo normas, geriau tinkamą nuo skriaudymo ir cheminio poveikio, taip pat leidžia geresnį susidomėjimą.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ