Overview

Inquiry

Related Products

-

1. The material of effective drying liner is 304 stainless steel, with high cleanliness feature.

-

2. with opening type design, very portable and convenient to test and maintenance.

-

3. The adjustable foot cup and the universal wheel is equipped easy to transport and install.

-

4.The conveyor speed can be adjustable according to your requirements

-

5.The touch screen with PLC control can be provided

-

6. Inside and outside of produce is heated evenly, the quality is stable, not deformed, not discolored.

-

7. It can be used with the automatic spraying line and production line, which can effectively control the labor, reducing the handing, reducing the bad product, saving time.

-

8. The temperature can be controller in sections to adapt the change of product, the reasonable temperature curve make the quality more stablemate-explosion and environmental protection.

-

9. The shell surface temperature is almost 40℃, can be touch by hand, which can reduce the energy consumption. The working environment will be more comfortable.

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

- Manipulator, Spraying robot etc Industrial Robot equipment

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

Xinqinfeng

Hydrographic Drying Machine, the answer is clear ultimate all of your drying needs. Fashioned with cutting-edge technology and high-grade materials, this device is drying your hydrographic prints are dry out quickly and effortlessly.

The Xinqinfeng Hydrographic Drying Machine is fantastic for those that end up buying reliable and hassle-free solution is drying. Its practical design makes it easy to take advantage of, while its effective system is drying that your particular images dry very quickly.

This device is drying appropriate for a myriad of hydrographic movies and offers constant results each and each time. All of it whether you're looking after a tiny or major project, this machine are designed for.

The Xinqinfeng Hydrographic Drying Machine includes a program is user-friendly makes it simple to work. It features a feeling screen display offering you with step-by-step information on the process is drying just like the temperature and time. This permits anyone to modify the settings predicated on your specific requirements, providing you with control is complete of method that drying.

The machine is drying features multiple racks, letting you dry multiple prints during the same time. This feature is particular decreases enough time that drying making it perfect for high-volume publishing tasks.

The Xinqinfeng Hydrographic Drying Machine is built to last, with a durable and construction is certainly robust. It really is made out of top-quality materials and this can be resistant to wear and tear, making it will probably withstand heavy usage over a period is extended.

This machine is drying simple to keep, by having a straightforward cleaning procedure that requires effort is minimum. It really is made to be energy-efficient, cutting your power costs and contributing to a much more environment is sustainable.

Production Features:

Product Specification:

|

No. |

Item |

Specification |

|

A |

The conveyor line of Drying oven |

Size:L2200mm×W600mm×H750mm(Qty:1pcs ) |

|

1 |

Material |

The body of equipment is made of 1.2t 50# box section. The foot of the machine is made of welding 50x50 steel box section. The foot stool is equipped with M12 adjustable foot cup. The adjustable height is 1050±20. the feeding area is 1m,the heating area is 1m |

|

2 |

The conveyor line |

The conveyor adopts the Teflon high temperature mesh belt with black double knit. The effective width is 400mm |

|

3 |

Motor |

The motor use the Taiwan imported 40W electronic speed regulating motor. The Main speed ratio of gearbox is 1:60 and the speed of the conveyor is 0.1-2m/min. |

|

4 |

Driving System |

A set of seamless tube precision machinery processing and production of the transmission chain wheel, a set of belt pulley. |

|

5 |

Painting color |

Computer white electrostatic powder coating |

|

B |

Drying furnace cover |

Size:L1000mm×W510mm×H100mm(Quantity: 1pcs) |

|

1 |

The outside plate material |

The outside plate is made of 1.2t folding welding cold plate. The inner plate is made of 1.0t galvanized sheets. The thick of heat insulation layer is 50mm. |

|

2 |

The electrical heated tube |

It uses quartz infrared heating tube, the power is 4KW/set. |

|

4 |

Temperature |

The design temperature is adjusted from room temperature to 250℃. |

|

5 |

Wind Motor |

The wind motor use 60W vertical high temperature resistant motor, which is equipped with 4 inch fan blade to form wind system. |

|

6 |

Electronic Controller |

The temperature-controller uses the Japan RKC digital display temperature controller. The control circuits has electric relay switch with indicator light, electric relay, contactor etc. and it has the overload protection. |

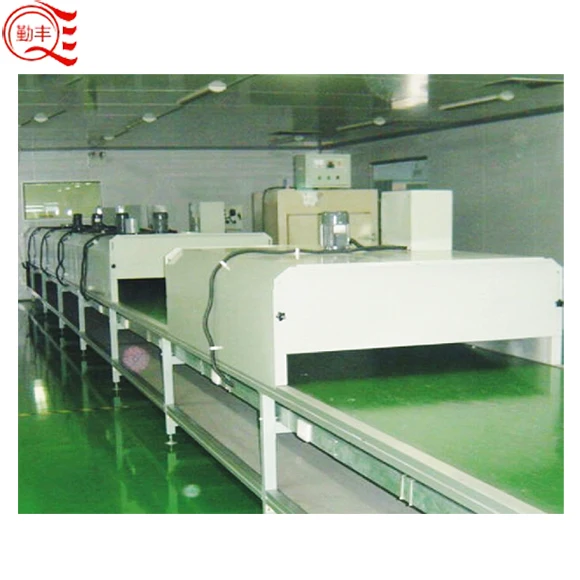

Product Pictures:

Tunnel Furnace Application:

Tunnel furnace the equipment is widely used in electronics, plastics, flooring, textiles, food, coating, electroplating, chemical, leather, woodworking, paper products, shoemaking, medicine, hardware printing, mobile phone assembly, semiconductor and other industries.It can be seen that the operation of tunnel furnace equipment is widely used in these fields. However, tunnel furnace equipment is widely used in the production of dispensing line for electronic components, inductor dispensing, capacitor dispensing, PCB board sealing, network transformer dispensing, arts and crafts dispensing, LED dispensing and painting industry

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

4.Q: What is price of the machine?

Answer: Normally, Most of the machine is customized for our customer. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please send us the detail infos about your workpiece as blow:

1. The maximum size of workpiece:

2. The material of workpiece:

3. The drying temperature:

4. The drying time:

Our Service

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine

Appreciating for your support, if you can send us some pics with product size and capacity for reference. Once get your infos, We will send you our solution with price ASAP.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ