Overview

Inquiry

Related Products

-

Whole factory plastic parts automatic dust coating equipment

-

Whole plant metal products electrostatic coating equipment

-

Whole factory furniture electrostatic coating equipment

-

Whole plant locomotive, motorcycle coating equipment

-

Manipulator, Spraying robot etc Industrial Robot equipment

-

Automatic UV curing furnace line

-

Fully automatic electrostatic dust removal equipment

-

DISK automatic electrostatic coating equipment

-

All kinds of Drying,silk-screen equipment

-

All kinds of PVC/SUS belt,Nylon conveyor equipment

-

Teflon/Ceramic powder /PE immersion high temperature equipment

-

All kinds of Water Curtain Booth etc equipment

-

High level Air Supply System

-

Waste water/waste gas recycling system

-

Whole plant electroplating coating equipment

-

Whole factory electrophoresis coating equipment

Xinqinfeng

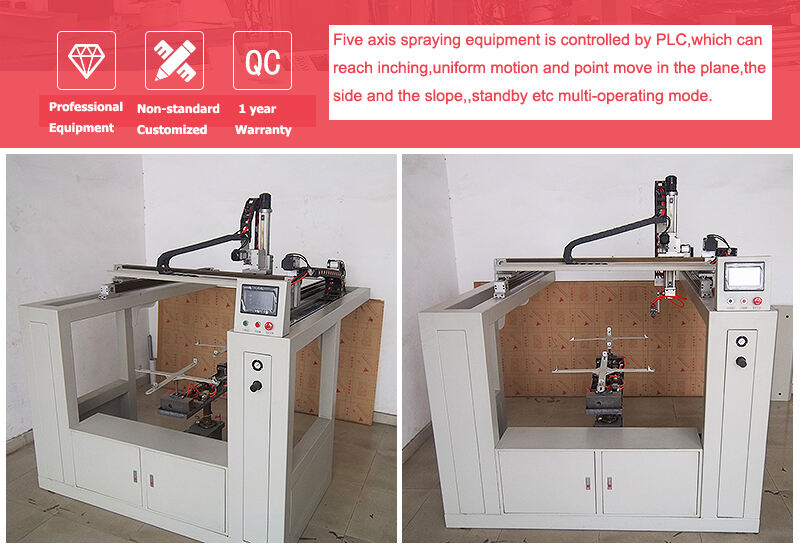

Automatic Spray Coating Machine for Painting Line could be the device is certainly ideal expert and efficient paint application in several companies. This coating device means that your paint job is wholly applied without the smudges or drips alongside its level is advanced technology.

The Xinqinfeng Automatic Spray Coating Machine for Painting Line is equipped with advanced functions that produce your paint job effortless and seamless. The apparatus's spray nozzle is run on an engine is high-speed assures a movement that is constant of, although the spray weapon is straightforward to go, which makes it easy to enter into tight areas. The device additionally has air is system that adjustable allows anyone to get a handle on the output for the paint.

This spray coating device is incredibly versatile and certainly will be utilized for many different surfaces, including steel, plastic, wood, and much more. And that means you will make utilization of the Xinqinfeng Automatic Spray Coating Machine for Painting Line to quickly attain a smooth and coating this is certainly constant of on nearly every product.

The Xinqinfeng Automatic Spray Coating machine for Painting Line can be extremely user-friendly also. A manual is included by the machine is detailed provides step-by-step directions about how to take advantage of it successfully. Additionally, the unit was made to be simple to clean and maintain, making certain it continues to work effectively for many years to come.

The Xinqinfeng Automatic Spray Coating Machine for Painting Line is made with safety features that ensure that the particular paint job is performed without having any injury to you or those around you with regards to security. It has an address is protective stops any paint from splashing back in the operator, whilst the device may be built with an air conditioning filter that ensures that no pollutants are released in the atmosphere during usage.

Production Features:

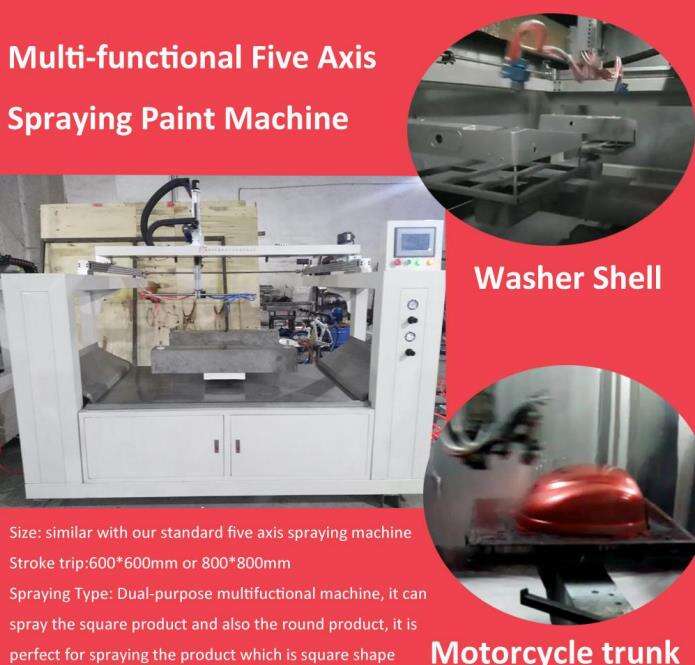

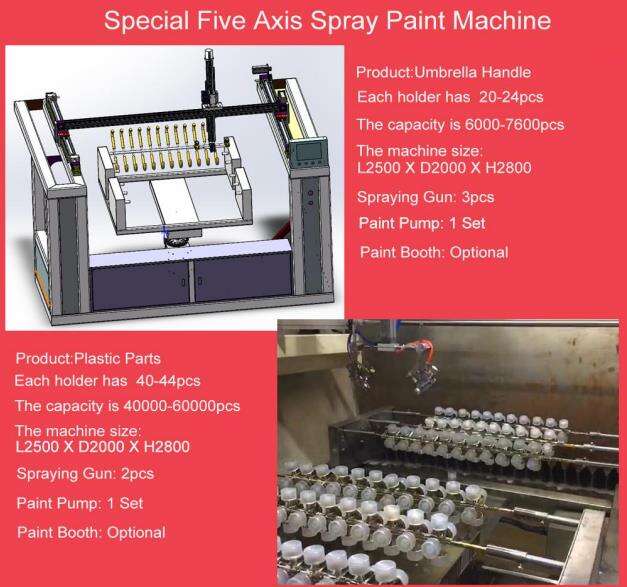

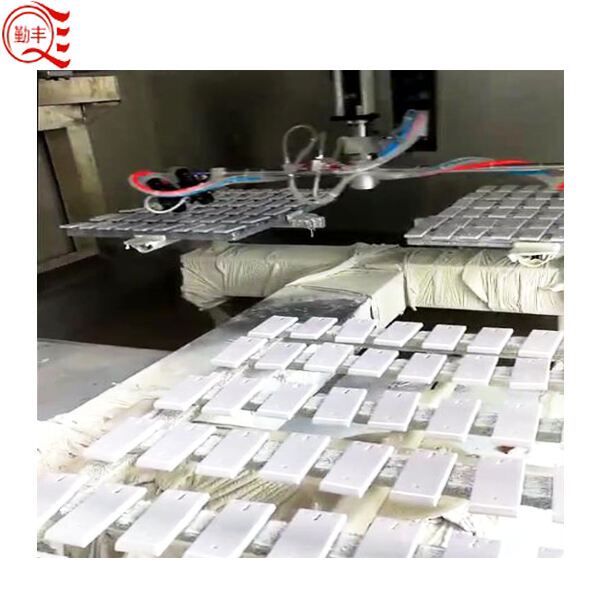

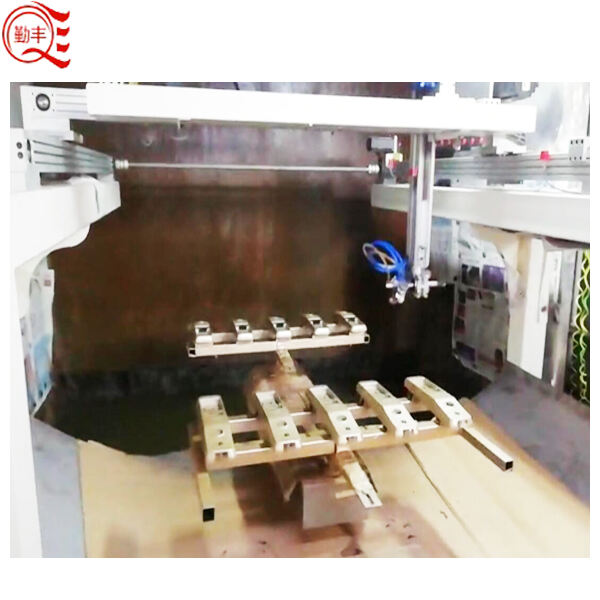

The five axis reciprocating spraying machine with air spraying system will help you get a good coating film and reduce the manual cost. The details of automatic five axis spraying machine are as follows.

1. This machine is widely used in many industry. Generally speaking, standard type of this machine has two product tray. If you want to buy a machine with four product tray, then you will get double yield under the premise of high quality coating.

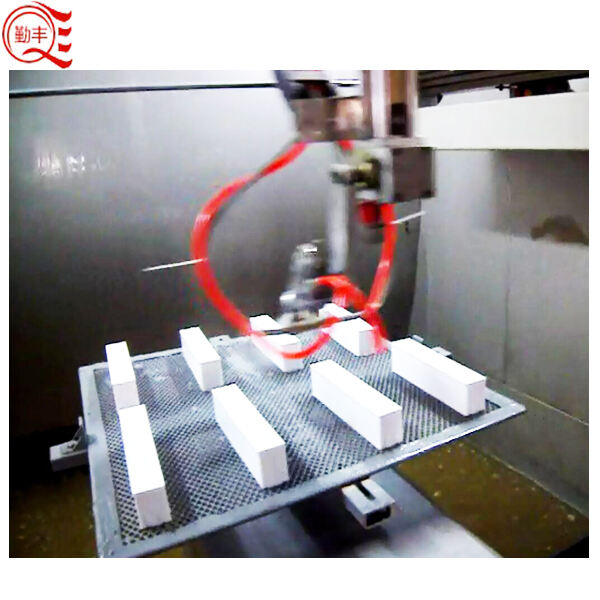

2. It is easy to debug the machine. You can finish debugging for usual product in 15 minutes. The program writing of machine is regard one plane of product as a program segment. When you finish setting the start point, end point and the spraying speed, then you have finished a program segment. After finish every program of plane, then the complete program is finished.

3. This machine has continuous spraying method and step spraying method.

4. The atomization and sector, painting output of spray gun can be controlled by computer. When the machine begin to spray, the spray gun can blow, in order to blow dust.

5. It is easy to use this machine, and you can store 160 programs of product. The machine operated by fully digital computer.

Product Specification:

|

SPECIFICATIONS FOR FIVE AXIS MACHINE |

||

|

Control system

|

1. The PLC use TAIWAN FATEK Brand 4.The switching power supply use the Taiwan MEANWELL power 5.The Proximity switch and reply use the Japan OMRAON brand |

|

|

Aluminum profile module |

Our own mold |

|

|

Drive system |

The servo motor driving use Taiwan DELTA brand |

|

|

|

1.Aluminum profile module 6.Rack and pinion drive |

|

|

Product exchange platform |

1.Precision splitter: Flange Model 140/180DF, high precision, high speed 3.tricrystal transducer control |

|

|

Product rotation platform |

1..Precision splitter |

|

|

Spray gun |

1. Automatic spraying guns: Japan ANEST IWATA brand WA-101 series automatic spraying. the caliber is 1.0mm 2.The power use Japan SAMSR stepping motor 3.The degree of horizontal travel for the gun: 0-180 degree |

|

|

Programming mode |

Off line programming |

|

|

Power supply |

4KW |

Production Features:

The five axis reciprocating spraying machine with air spraying system will help you get a good coating film and reduce the manual cost. The details of automatic five axis spraying machine are as follows.

1. This machine is widely used in many industry. Generally speaking , standard type of this machine has two product tray. If you want to buy a machine with four product tray, then you will get double yield under the premise of high quality coating.

2. It is easy to debug the machine. You can finish debugging for usual product in 15 minutes. The program writing of machine is regard one plane of product as a program segment. When you finish setting the start point , end point and the spraying speed, then you have finished a program segment. After finish every program of plane, then the complete program is finished.

3.This machine has continuous spraying method and step spraying method.

4.The atomization and sector, painting output of spray gun can be controlled by computer. When the machine begin to spray , the spray gun can blow, in order to blow dust.

5.It is easy to use this machine ,and you can store 160 programs of product. The machine operated by fully digital computer.

Product Specification:

|

SPECIFICATIONS FOR FIVE AXIS MACHINE |

|

|

Control system

|

1.The PLC use TAIWAN FATEK Brand 4.The switching power supply use the Taiwan MEANWELL power 5.The Proximity switch and reply use the Japan OMRAON brand |

|

Aluminium profile module |

Our own mold |

|

Drive system |

The servo motor driving use Taiwan DELTA brand |

|

|

1.Aluminum profile module 6.Rack and pinion drive |

|

Product exchange platform |

1.Precision splitter:Flange Model 140/180DF, high precision, high speed 3.tricrystal transducer control |

|

Product rotation platform |

1..Precision splitter |

|

Spray gun |

1.Automatic spraying guns:Japan ANEST IWATA brand WA-101 series automatic spraying. the calibre is 1.0mm 2.The power use Janpan SAMSR stepping motor 3.The degree of horizontal travel for the gun: 0-180 degree |

|

Programming mode |

Off line programming |

|

Power supply |

4KW |

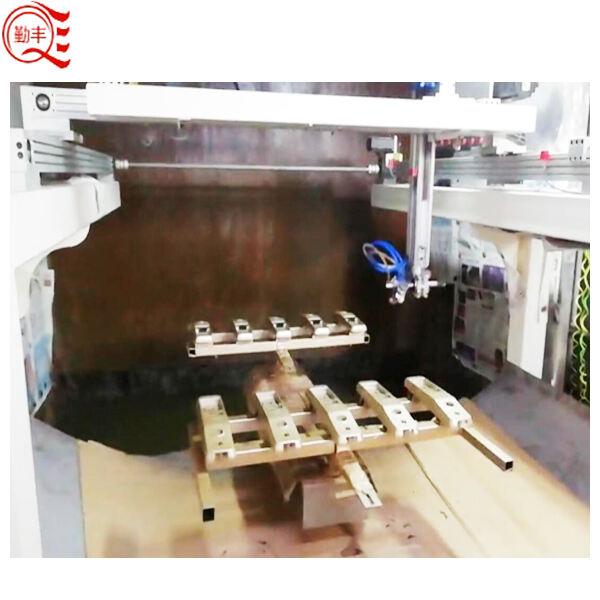

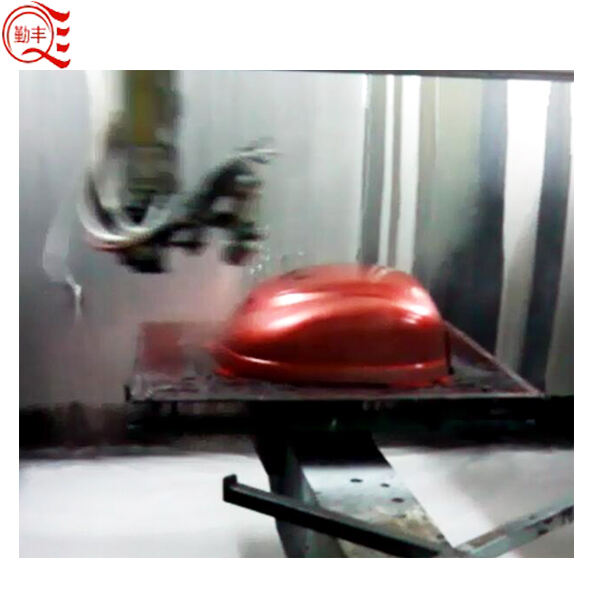

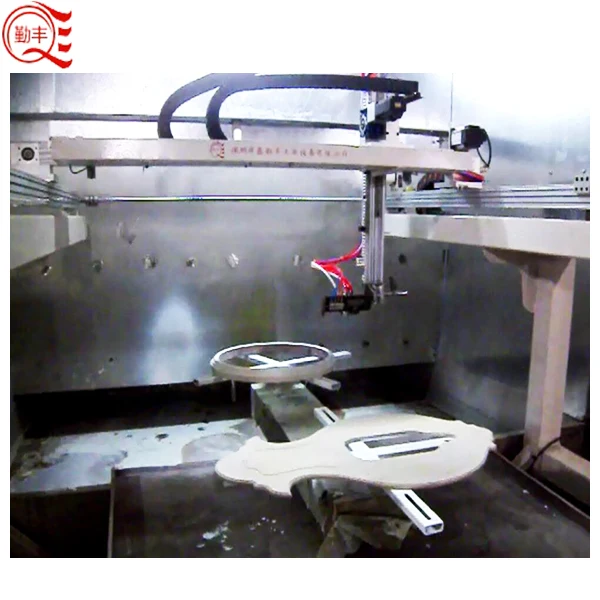

Product Pictures:

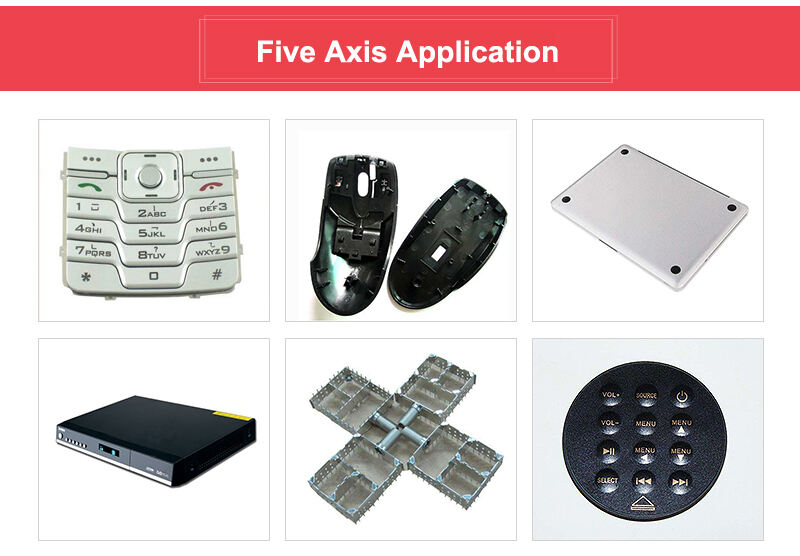

Application:

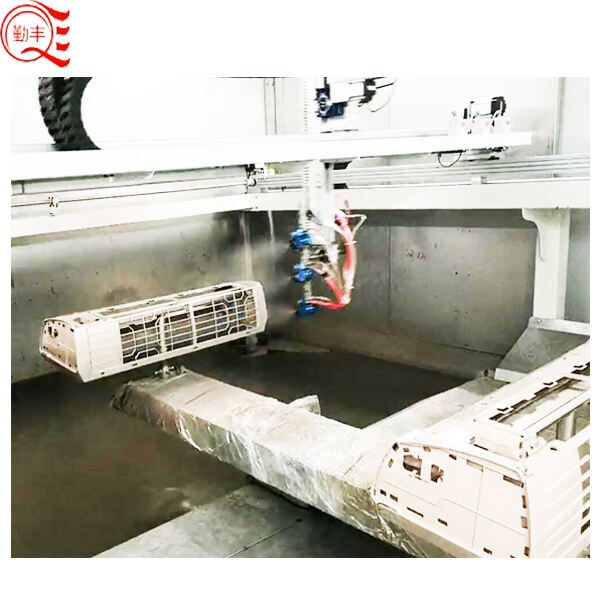

The five axis automatic spraying reciprocating machine is wildly used in the field of plastic, electronics,hardware handicraft, TV shell,computer panels,glass,toys, woodwork,magnet ring etc, also suit for large flat parts(such as door,glass) etc precision surface spraying. The spraying process can reach the surface spraying or multi-surface spraying. Multi-axis linkage spraying or one axis reciprocating movement is OK. The parameter is adjustable flexible.the programming is convenient and fast.

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household

appliances, medical equipment, metal products, construction machinery, mechanical and

electrical products, motorcycles and other metal products, wooden furiture, plastic products

and other types of products.

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

FAQ

Question 1: I don't know anything about the machine. Will you provide the technical support?

Answer: Sure. Every machine will be test before delivery. We will make sure there is no problem for the machine while it leave our factory.

When the equipment is small and standard ,such as five axis spraying equipment,mini spraying line, small tunnel furnance or ovens,spraying power booth,curing furnace etc, We can send the detailed user manual and video to

help you install and operate the equipment. Of course,You can arrange 2-3 smart workers to come to our factory to learn how to operate the machine.

If the machine is spraying line and big,When the machine arrives your factory, we will send the experts to your factory to help for installation and commissioning. Operation training will be provide. Maintenance tips will be given and enough spare parts be provided.

Also, we provide consulting service for creating the proper facilities for running the machine.

Question 2: What is price of the machine?

Answer: Normally, Most of the machine is customized for our customer. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please send us the detail infos about your workpiece as blow:

1. The maximum size of workpiece:

2. The max weight of workpiece:

3. The output per month/per day:

4. Heating Temperature and Time(If you need the drying equipment):

5. Color changing(How many colors? How long will it take to change other colors ?)

6. Spraying process(What paint will you use? Spraying times? )

7. The workshop size for the equipment:

8. Some work-piece pics are needed:

9. The power: industrial three phase voltage

10. Other requirements from customer:

Once get your infos,We will provide our professional suggestions and work out an appropriate design for your project.Then the quotation with detail specification will be offered to you ASAP.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ