Overview

Inquiry

Related Products

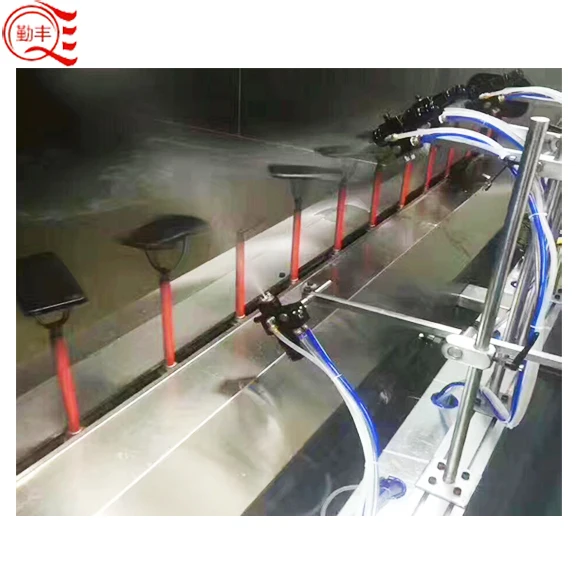

Automatic spray paint line includes the automatic dust removing, automatic spraying paint, automatic drying and automatic cooling, Save labor and cost, improve the efficiency

Spray evenly, high precision, the running accuracy is within 0.2mm, the spraying accuracy is within 0.2-1mm

Flexible spraying size can save 20% paint

High efficiency, can reach continuous work for 24 hours, the output is 3-5 times than the labor

Fully visual touch screen control, operate easily, can save and read the data quickly

Spraying debugging is simple within ten mins, The program is easy to operate

Whole factory plastic parts automatic dust coating equipment

Whole plant metal products electrostatic coating equipment

Whole factory furniture electrostatic coating equipment

Whole plant locomotive, motorcycle coating equipment

Manipulator, spraying robot etc. Industrial Robot equipment

Automatic UV curing furnace line

Fully automatic electrostatic dust removal equipment

DISK automatic electrostatic coating equipment

All kinds of Drying, silk-screen equipment

All kinds of PVC/SUS belt, Nylon conveyor equipment

Teflon/Ceramic powder /PE immersion high temperature equipment

All kinds of Water Curtain Booth etc. equipment

High level Air Supply System

Waste water/waste gas recycling system

Whole plant electroplating coating equipment

Xinqinfeng

Electrostatic Painting Coating Production Line is a quality product which has been developed to offer reliable and outcomes that are consistent when it comes down to coating or artwork materials. This system is great for industrial settings where effectiveness is high finish quality are fundamental facets. The Xinqinfeng group has devote an entire amount is large of to ensure that the device is impressive, user-friendly, and cost-efficient.

The Electrostatic Painting Coating Production Line utilizes advanced technology to make certain an application is uniform. The machine was created to produce a good cost that electrostatic attracts the paint particles to the area that is prospective. This guarantees an even and coating is certainly consistent which eliminates potential for patchy or areas that are uneven.

The Xinqinfeng Electrostatic Painting Coating Production Line is also built to be user friendly. The device is operated via a control that is user-friendly which was designed to supply an array of choices and settings that allow you to modify the application form procedure according to your requirements. The device normally made to be easily maintained as its constructed materials are utilizing could be top-notch are durable and long-lasting.

The Electrostatic Painting Coating Production Line is fantastic for any application where quality is certainly high finishes are lasting required. The flexibleness of the system means it may be utilized when it comes to number of applications, including automotive, aerospace, medical gear, and equipment is commercial. The device may be used to coat many different materials steel is including plastic and wood.

The device can be extremely cost-efficient also plus the quality and effectiveness concerning the Xinqinfeng Electrostatic Painting Coating Production Line. The device drastically decreases the amount of paint or coating product required, that leads to significant savings in materials costs with the use of an electrostatic cost to coat areas. The device also reduces the number of waste generated during the applying procedure, which further adds to the cost savings.

| Production Features: |

|

1.Loading --pretreatment --electrostatic degusting --bottom painting --surface drying --finishing painting --curving--cooling --unloading --vacuum metrication |

| Product Pictures: |

| Application: |

Automatic spray paint line are widely used to the workpiece which will be achieve high efficiency, high output.

Such as all kinds of bottle, wine bottle, Cosmetics bottles, cosmetic lid, glass cup, glass ball, hardware, plastic round disk, kitchen ware, helmet, rearview mirror etc. irregular shapes

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries. From a development department, Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment. After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

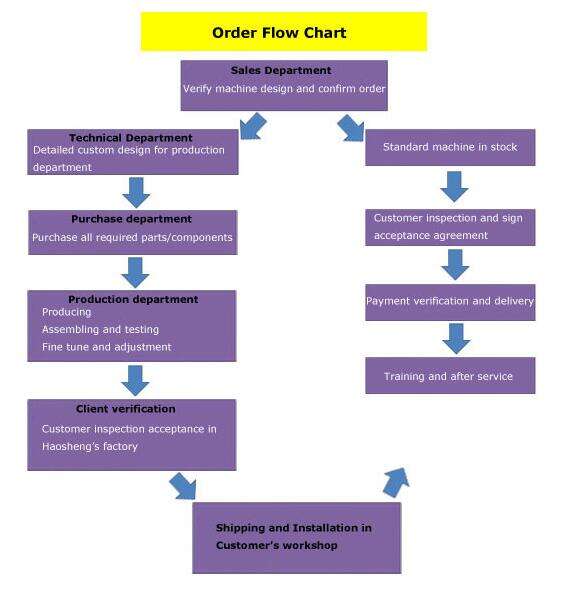

Our Service:

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ