Overview

Inquiry

Related Products

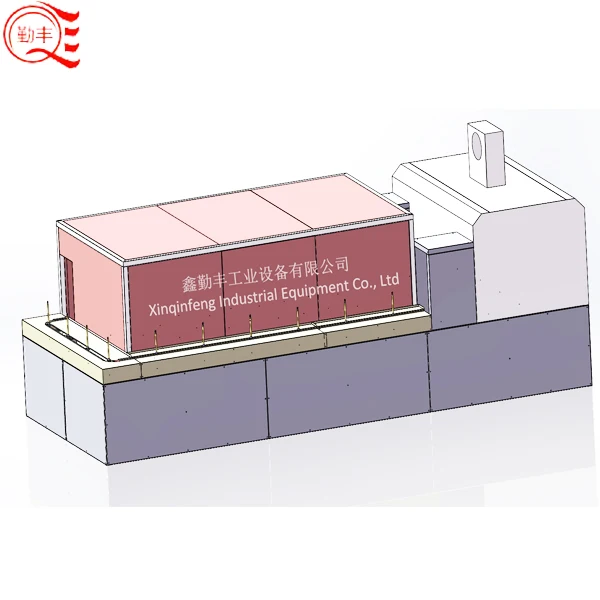

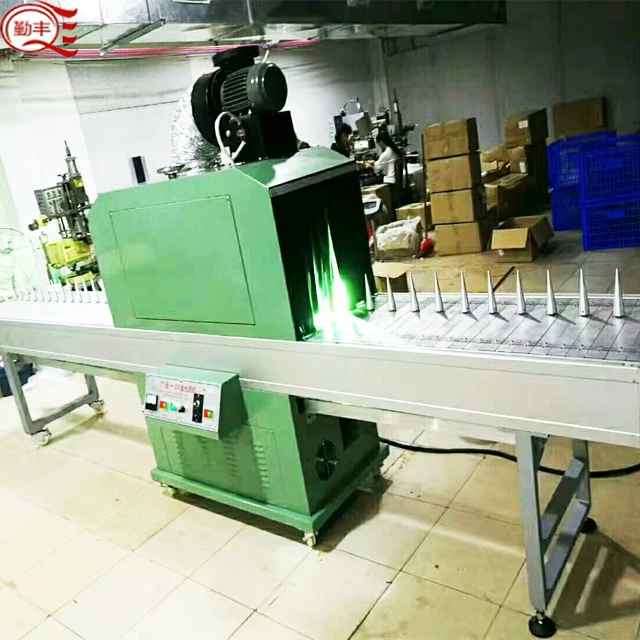

The Xinqinfeng IR + UV conveyor furnace is unquestionably an innovative piece and designed for efficiently drying switches and sockets. Made up of the latest technology, this method is ideal for any manufacturer seeking to increase speed for keeping top-quality outcomes.

The Xinqinfeng IR + UV conveyor furnace enables precise temperature control and efficient drying times having an easy-to-use software and intuitive settings. This machine combines both infrared (IR) and ultraviolet (UV) heating technology, making sure your switches and sockets are completely dry and prepared for use.

One of the key options that come because of the product may be the conveyor belt system. The seamless and style that is constant of gear ensures that each switch or socket gets equivalent level of heat exposure. This particular feature is very essential for bigger manufacturing runs, where accuracy and consistency are critical.

A concern this is certainly major any maker is efficiency. The Xinqinfeng IR + UV conveyor furnace ended up being fashioned with this in mind. This product can increase efficiency without dramatically compromising on quality insurance firms an output all of the option to 300 pieces each hour. This escalation in production speed is a game-changer for companies wanting to remain competitive in a market this is certainly ever-changing.

Security can be a problem this is certainly top Xinqinfeng, and also the IR + UV conveyor furnace is made with a security that is few. A crisis ends shutdown and key that is automatic 10 moments of inactivity make sure that your workers will always protected while using this product.

The Xinqinfeng IR + UV conveyor furnace isn't only effective and efficient, but it is additionally built to final. The construction this is certainly sturdy durable materials make sure that this gear will still be an essential part of one's production line for a long time for you to come.

Product Description

A. Instant drying; avoid drying waiting time, greatly reducing the coating process time.

B. It can be directly connected with the coating machine. The machine can be connected to the drum type or curtain coating machine. After coating, the finished product is directly dried, eliminating the trouble of handling.

C. Coating surface hardness increased, bright color.

D. Extensive drying function: wood, plywood, furniture, steel, building materials, lenses, leather and other UV coating after drying.

Product Specification:

|

No. |

Item |

Specification |

|

A,UV Curing Oven (one set) |

||

|

1 |

The Conveyor Chain |

The conveyor chain uses special chain of automatic line. the pitch is 50.8mm, the total length is 8500m. Each two-pitch distance use one special fixture for the product. |

|

2 |

The Motor |

The motor use Taiwan imported 0.5HP gear reducer motor to transmission. The speed of chain is adjusted by adopting 1HP ZONCN frequency transformer. The chain speed is adjustable within 1m/min- 6m/min. The frequency control of the motor speed is energy saving. |

|

3 |

The rack |

The rack is made of welding 50# square box section. The bottom of rack has the truckle and foot cup. The height is adjustable. |

|

4 |

The sealed plate |

The rack is sealed by the plate, the surface treatment is stainless steel primary color |

|

B, UV furnace (one set) Furnace size:L1700mm*W1500mm*H1910mm |

||

|

1 |

Outside plate |

The outside plate of curing furnace is made of 1.2t 201#Stainless steel plate, |

|

2 |

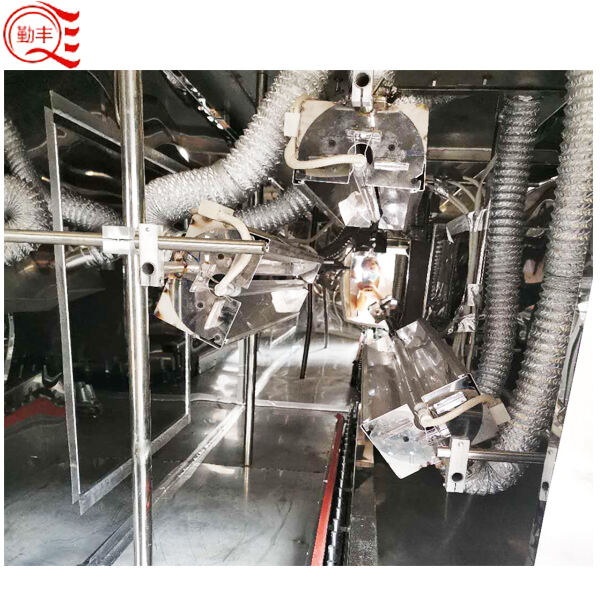

The light box |

It is making of mirror stainless steel plate; the thickness of steel plate is 1.2mm. |

|

3 |

The lamp |

The lamp uses domestic high-quality WUZHOU brand 5.6KW UV lamp with 3pcs. The Lamp can be controlled with strong, medium and weak three switch. The UV lamp is Equipped with the transformer and the capacitor which are installed inside the Frame. |

|

4 |

Cooling System |

1.1KW centrifugal high-pressure suction fan are used in the Upper part of the UV curing ovens. It is mainly used to cooling The temperature of fan and drain the paint mist |

|

5 |

Electronic Controller |

The main electrical components adopts Taiwan brand components’ lamp ammeter, electric lamp running time-accumulator, overtemperature indicator light, power indicator etc. |

|

C |

Drying furnace cover |

The inner size is L3000mm×W2300mm×H350mm(effective height) |

|

1 |

The outside size of furnace |

L3000mm×W2250mm×H500mm(including the suction section on both ends) |

|

2 |

The outside plate material |

The outside plate is made of 1.2t folding welding cold plate. The inner plate of furnace cover is made of 1.0t galvanized sheets. 50mm thick insulation cotton is filled up. The outside of insulation board is made of 1.0t galvanized sheets. The inner layers is filled up 30mm insulation cotton. The maximum effective height of the product is 350mm. The height is adjustable. |

|

3 |

The electrical heated tube |

It uses quartz infrared heating tube. The height between the product and light is 200mm. The total power is12KW. |

|

4 |

The wind motor |

Each part has the hot air circulating system. The power is 180W. 4-inch special fan blade make the heat flowing evenly in the furnace come true. |

|

5 |

Temperature |

The design temperature is adjusted from room temperature to 80℃. the temperature differential is plus and minus 5℃ |

|

6 |

Electronic Controller |

The temperature-controller uses the Taiwan Berme digital display temperature controller. The control circuits has electric relay switch with indicator light, electric relay, contactor etc. and it has the overload protection. Each furnace is controlled independently. The Electronic controller of the three furnace will be designed in one electrical box. Easy to operate |

|

7 |

Surface treatment |

Stainless steel primary color |

Product Pictures:

Application:

UV curing has been widely adopted in many industries including automotive, telecommunications, electronics, graphic arts, converting and metal, glass and plastic decorating.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ