Overview

Inquiry

Related Products

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

- Manipulator, Spraying robot etc Industrial Robot equipment

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

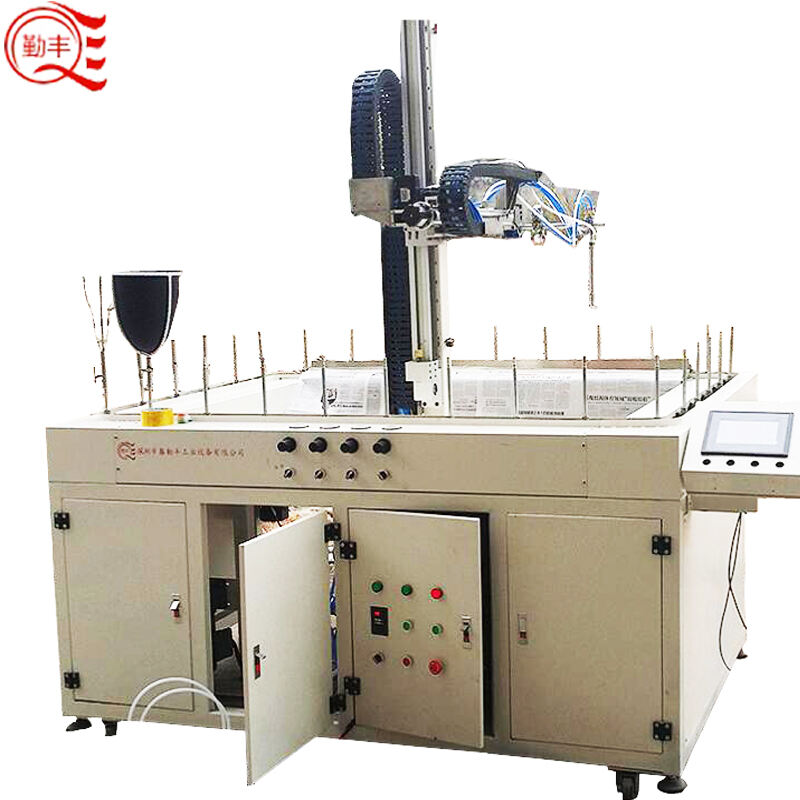

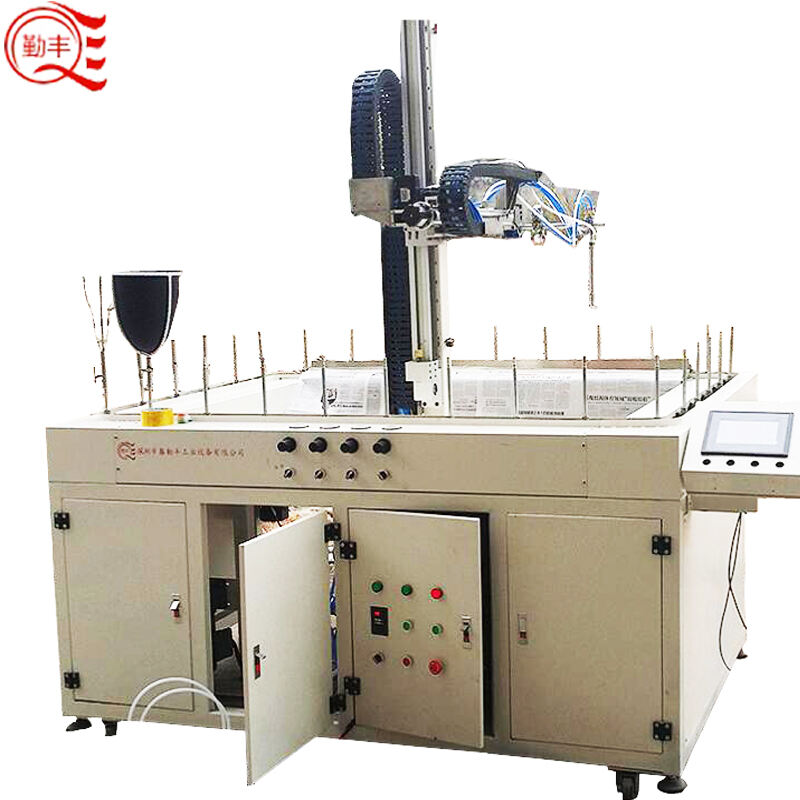

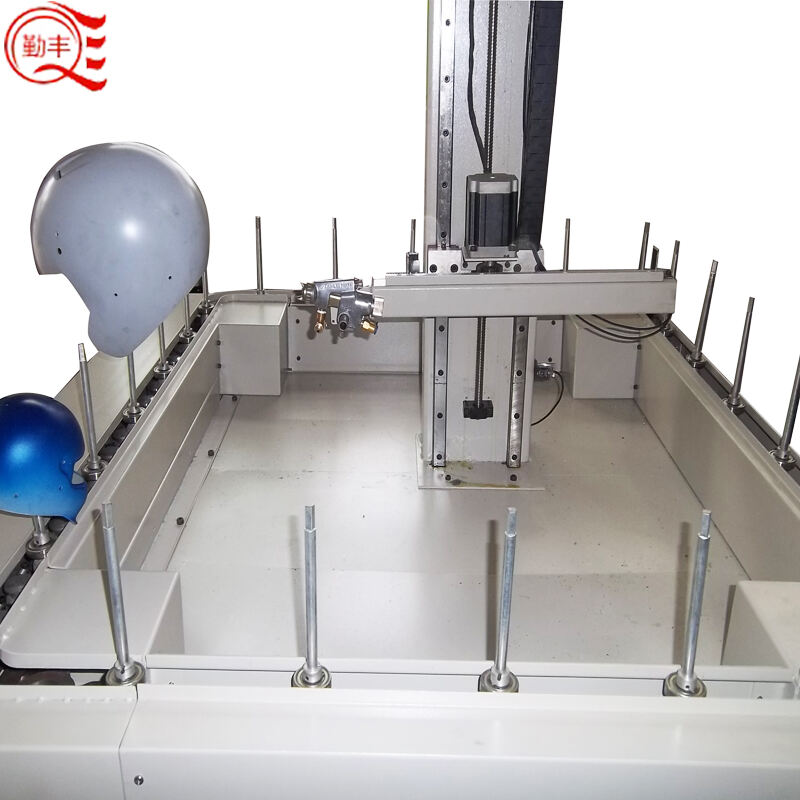

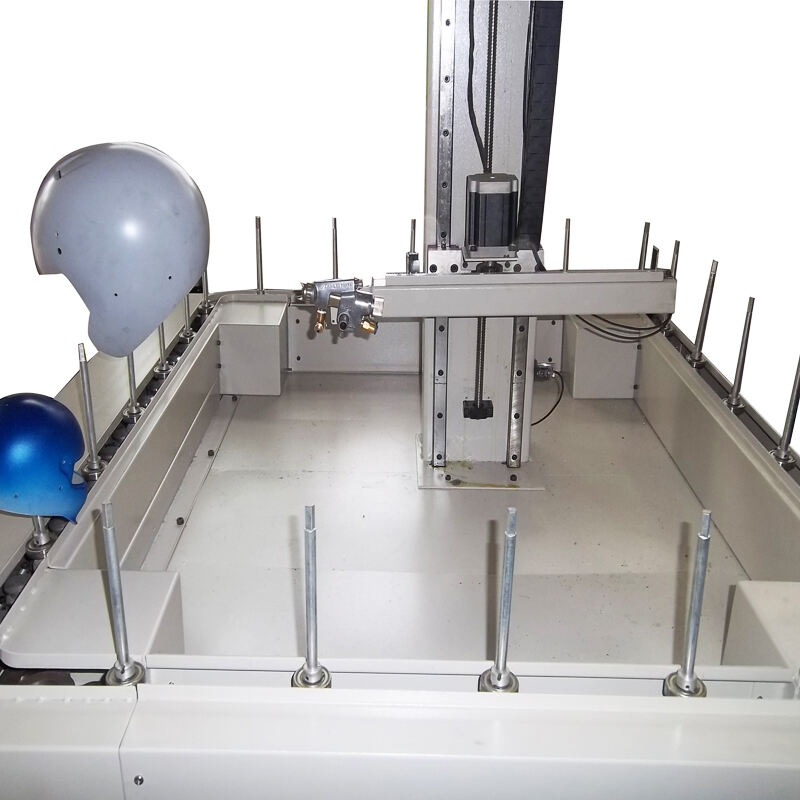

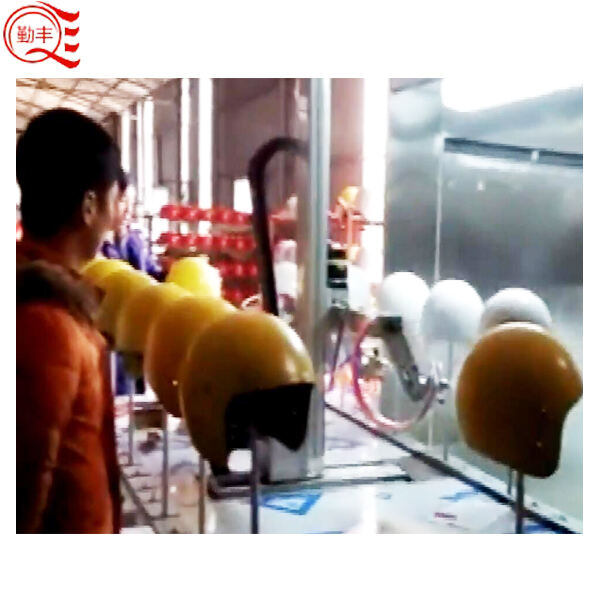

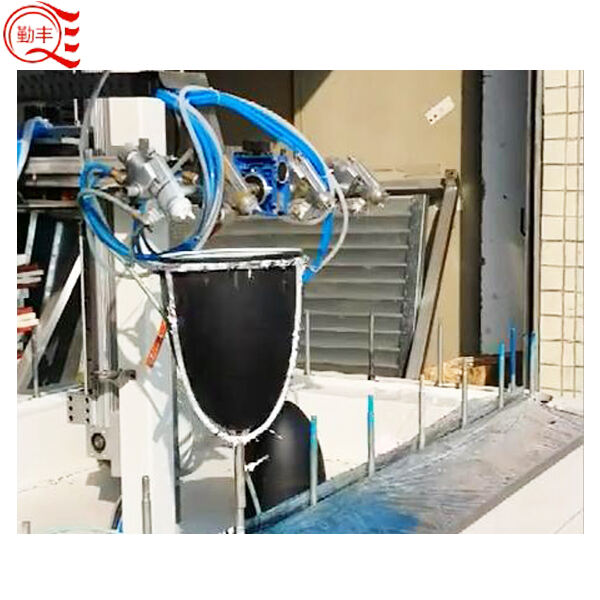

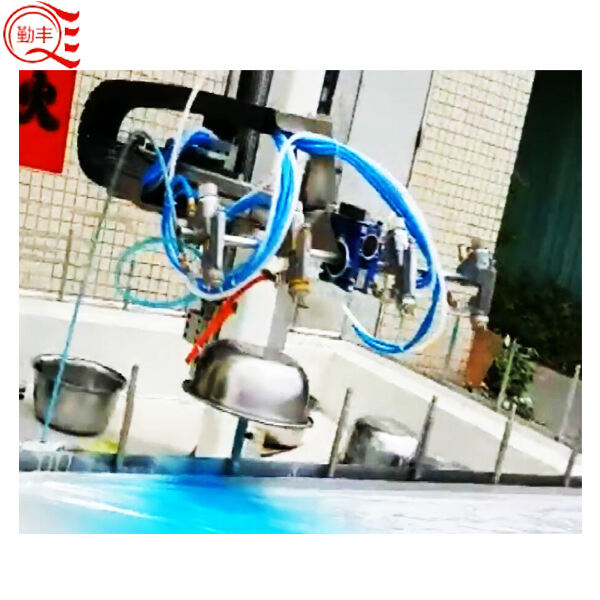

Three axis spray paint equipment automatic paint spraying machine for helmet

Production Features:

1.The three axis reciprocating spraying machine with air spraying system will help you get a good coating film and reduce the manual cost.

2. Small Size, working range big,high speed, high precise,the spraying effect is best for high quality product.

3.Flexible, it can achieve the inner part spraying ,outer part spraying,and tall product spraying

4.The operate is easy and simple, which can be controled by the touch screen.

5. It can come ture for fixed gun spraying, stepping type spraying and continuous type spraying.

Product Specification:

|

Item |

Remark |

|

Horizontal Posterior -anterior direction(DPA)

X-Axis slide platform |

1. The sliding rail use 15 series flange type self lubricating linear guideway from Taiwan Hiwin brand with aluminum alloy module slider. The maximum drive speed can reach 2.0M/S,long operating life.The belt adopts 5m wire-steel synchronous belt from imported brand; 2. The Accuracy of Reciprocating is 0.1mm, the Accuracy of Positioning is 0.1mm; 3. The effective spraying area is within 200mm,the Reciprocating travel of X-axis ≥200mm; 4. X-Axis adopts the200W low-inertia servo motor driving from Taiwan DELTA brand; 5. A set of slider in X-Axis. |

|

Vertical up-down Direction (DDU)

Z-Axis elevation machine |

1. The sliding rail use 25 series flange type self lubricating linear guideway from Taiwan Hiwin brand with aluminum alloy module slider. The maximum drive speed can reach 1.5M/S,long operating life.The belt adopts 5m wire-steel synchronous belt from imported brand; 2. The Accuracy of Reciprocating is 0.1mm, the Accuracy of Positioning is 0.1mm; 3. The effective spraying area is within 600mm, the Reciprocating travel of Z-Axis ≥600mm; 4.Z-Axis adopts the 400W low-inertia servo motor driving from Taiwan DELTA brand; 5. A set of slider in Z-Axis. |

|

W-Axis Internal and external rotating gun mechanism |

P-Axis adopts direct motor,the structure is simply and durable,the motor is placed in the top.Then it Will completely avoid the surface pollution of the motor caused by the painting mist bounced. There is the exclusive extension structure of low-pressure spray gun. It is convenient to spray the side of the product in smaller gap when spraying some small and medium workpiece. 1. The error of positioning in P-Axis ≤ 90′; 2. The degree of horizontal travel for the gun: 0-180 degree; 3. P-Axis use the 57 stepping motor system, 5m belt pulley power train configuration; 4. P-Axis has one rotating gun mechanism. |

|

Numerical control function and configuration |

On-line intermittent spraying type The touch screen use the Beijing MCGS Brand TPC7062KX series touch screen. The PLC use the Taiwan FATEK brand FBS-40MCT2AC series product. |

|

Electronic control system |

1. The air switch use the CHINT brand components; 2. The switching power supply use the Taiwan MEANWELL power; 3. It use the Japan OMRAON brand original proximity switch and reply; 4. The circuit use the GB-line to be assembled in the case; 5. All joints are marked with wire ear and computer code; 6. Adopting independent electric control box will prevent the electrical elements from being damaged from the paint,water,dust effectively and reduce the fire hazards. |

|

Pneumatic Circuit |

The pressure regulating valve,barometer,electromagnetic valve and wind pipe are all adopt well-know brand products.The brand is slightly different due to the inventory changes. |

|

Spray gun and other accessories |

1. The guns use 6pc the Japan ANEST IWATA brand 101 series automatic spraying gun, One set gun rack is equipped and the center of rotation is fixed. 2.1 set pumps are equipped.the joins is trisection. 3.one set of oil pipe; 4. Oil pipe, air pipe,oil-water separator, pressure regulating valve, electromagnetic valve are equipped. |

|

The cable and drag chain |

1. The high speed silent special drag chain can effectively avoid the noise problems caused by the tank chain during the high speed reciprocation. 2. All the tank chains are arranged in a clockwise direction , which will avoid the case appears when the tank chain has a transverse force, it will be break off easily. 3. It is installed on the U slot, which will avoid dust scattered to the sprayed workpiece. 4.The cable use silicon soft wire which is perfect for the frequent reciprocating motion. Longer life time than the regular wires. |

|

Major Structure |

1. The rack is made of national standard square welding, fully taking into account the mechanical design of materials, good stability. 2. The overall size is: L2200 * D1500 * H2500, surface treatment for electrostatic dusting, strong and difficult to scratch.The surface treatment is electrostatic spraying power treatment. Solidly and not easy to scratch. 3. The bottom is equipped with a stainless steel basin. |

|

Gun and fuel supply system |

1. Automatic spraying guns:Japan ANEST IWATA brand WA-101 series automatic spraying. the calibre is 1.0mm. The qty is 4pcs. 2. 2 set pumps are equipped.the joins is trisection. 3. Two set of oil pipe; 4. Oil pipe, air pipe,oil-water separator, pressure regulating valve, electromagnetic valve are equipped. |

Product Pictures:

Application:

The three axis spraying paint machine is wildly used for big round product or tall round product, such as the helmet,pot,led lamp shell,glass cup or bottle,kettle and baseball bat etc

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Company Pictures

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household

appliances, medical equipment, metal products, construction machinery, mechanical and

electrical products, motorcycles and other metal products, wooden furiture, plastic products

and other types of products.

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

FAQ

Question 1: I don't know anything about the machine. Will you provide the technical support?

Answer: Sure. Every machine will be test before delivery. We will make sure there is no problem for the machine while it leave our factory.

When the equipment is small and standard ,such as five axis spraying equipment,mini spraying line, small tunnel furnance or ovens,spraying power booth,curing furnace etc, We can send the detailed user manual and video to

help you install and operate the equipment. Of course,You can arrange 2-3 smart workers to come to our factory to learn how to operate the machine.

If the machine is spraying line and big,When the machine arrives your factory, we will send the experts to your factory to help for installation and commissioning. Operation training will be provide. Maintenance tips will be given and enough spare parts be provided.

Also, we provide consulting service for creating the proper facilities for running the machine.

Question 2: What is price of the machine?

Answer: Normally, Most of the machine is customized for our customer. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please send us the detail infos about your workpiece as blow:

1. The maximum size of workpiece:

2. The max weight of workpiece:

3. The output per month/per day:

4. Heating Temperature and Time(If you need the drying equipment):

5. Color changing(How many colors? How long will it take to change other colors ?)

6. Spraying process(What paint will you use? Spraying times? )

7. The workshop size for the equipment:

8. Some work-piece pics are needed:

9. The power: industrial three phase voltage

10. Other requirements from customer:

PLS sent us your product pictures, maximum size, capacity,Then We will provide our professional suggestions and work out an appropriate design for your project.The quotation with detail will be offered to you ASAP.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ