Tổng quan

Truy vấn

Sản phẩm liên quan

- Thiết bị phủ bụi tự động cho phụ tùng nhựa toàn nhà máy

- Thiết bị phủ tĩnh điện cho sản phẩm kim loại toàn nhà máy

- Thiết bị phủ điện estát toàn nhà máy nội thất

- Thiết bị phủ toàn nhà máy cho đầu máy toa xe, xe máy

- Cánh tay robot, S phun ing robot v.v. Thiết bị Robot công nghiệp

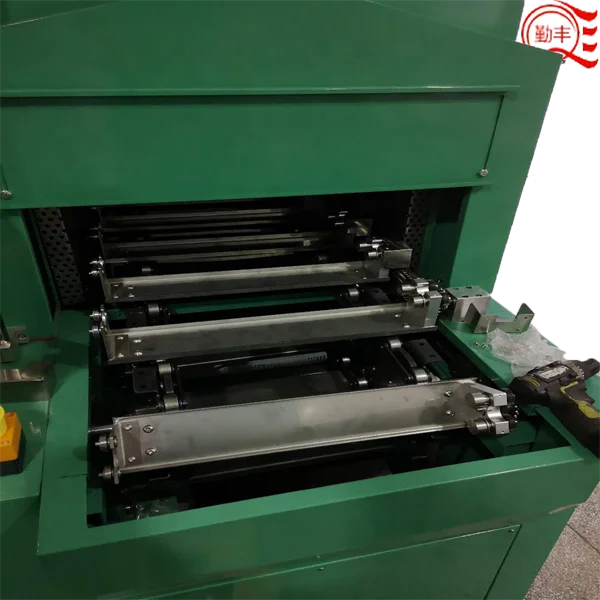

- Dây chuyền lò sấy UV tự động

- Thiết bị loại bỏ bụi điện estát hoàn toàn tự động

- Thiết bị phủ điện estát tự động DISK

- Các loại thiết bị sấy khô, in lưới

- Các loại thiết bị băng tải PVC/SUS, Nylon

- Thiết bị ngâm nhiệt độ cao bằng bột Teflon/Ceramic/PE

- Các loại thiết bị Booth màn nước, v.v.

- Hệ thống Cung cấp Không khí Cao cấp

- Hệ thống tái chế nước thải/khí thải

- Thiết bị mạ điện toàn nhà máy

- Thiết bị phủ điện phân toàn nhà máy

Lò công nghiệp thiết bị sưởi ấm phòng thí nghiệm lò hầm

Lò công nghiệp điều khiển nhiệt độ

Ứng dụng Lò Nung Hầm:

Thiết bị lò nung hầm được sử dụng rộng rãi trong các ngành điện tử, nhựa, sàn nhà, dệt may, thực phẩm, sơn phủ, mạ điện, hóa chất, da, gỗ, sản phẩm giấy, giày dép, dược phẩm, in ấn kim loại, lắp ráp điện thoại di động, bán dẫn và nhiều ngành khác. Có thể thấy rằng thiết bị lò nung hầm được sử dụng rộng rãi trong các lĩnh vực này. Tuy nhiên, thiết bị lò nung hầm được sử dụng rộng rãi trong việc sản xuất dây chuyền phun keo cho các linh kiện điện tử, phun keo cho cuộn cảm, phun keo cho tụ điện, niêm phong bảng PCB, phun keo cho biến áp mạng lưới, phun keo cho đồ thủ công mỹ nghệ, phun keo LED và ngành sơn.

Thâm Quyến X inqinfeng thiết bị công nghiệp co., LTD . w được thành lập vào năm 2004. Các sản phẩm được bán cho nhiều khu vực nơi trên khắp Trung Quốc đại lục và các quốc gia khác. Từ một phòng phát triển xinqinfeng có trở thành a nhà sản xuất chuyên nghiệp nào hiện đang chuyên về tự động hóa không tiêu chuẩn c thiết bị Cơ khí ’s phát triển, thiết kế và sản xuất ,với nhà máy lớn đạt tiêu chuẩn và thiết bị sản xuất hiện đại. Sau nhiều năm nỗ lực không ngừng và tích lũy , Hiện nay Xinqinfeng chuyên về thiết bị tự động hóa công nghiệp với quy mô và sức mạnh đáng kể.

Sản phẩm chính bao gồm bề mặt tự động sơn, sấy khô tự động, cũng như quy hoạch toàn bộ nhà máy phun sơn tự động , thiết kế ing và sản xuất, cũng như rô-bốt công nghiệp, rô-bốt, thiết bị tự động hóa và các thiết bị thử nghiệm không tiêu chuẩn khác.

Sản phẩm chính:

4.Q: Giá của máy là bao nhiêu?

Trả lời : Thông thường, hầu hết các máy móc đều được tùy chỉnh cho khách hàng. Nếu bạn có bất kỳ bản vẽ hoặc thông tin nào về thông số kỹ thuật của máy, vui lòng gửi cho chúng tôi để nhận báo giá.

Nếu bạn hoàn toàn mới trong lĩnh vực này, vui lòng gửi cho chúng tôi thông tin chi tiết về sản phẩm của bạn như sau:

1. Kích thước tối đa của sản phẩm:

2. Chất liệu của sản phẩm:

3. Nhiệt độ sấy:

4. Thời gian sấy:

Dịch vụ của Chúng tôi

Trước bán hàng:

1. Cung cấp lời khuyên chuyên nghiệp và đưa ra giải pháp tốt nhất cho khách hàng

2. Theo nhu cầu hoặc yêu cầu của khách hàng, kỹ sư của chúng tôi sẽ cung cấp bản vẽ và giải pháp cho bạn.

3. Chúng tôi sẽ cung cấp giá cạnh tranh theo giải pháp của khách hàng

Sau bán hàng:

1. Chúng tôi sẽ cử kỹ sư đến lắp đặt tại hiện trường, vận hành và đào tạo sử dụng.

2. Chúng tôi sẽ cung cấp dịch vụ xử lý sự cố và bảo hành trọn đời.

3. Chúng tôi cung cấp bảo hành 1 năm cho mỗi máy móc.

4. Chúng tôi sẽ liên hệ với bạn định kỳ để tìm hiểu tình trạng máy móc.

5. Chúng tôi cũng cung cấp dịch vụ mở rộng thêm cho máy móc hiện có của bạn.

Rất cảm ơn sự hỗ trợ của bạn, nếu bạn có thể gửi cho chúng tôi một số hình ảnh kèm theo kích thước và công suất sản phẩm để tham khảo. Ngay khi nhận được thông tin từ bạn, chúng tôi sẽ gửi cho bạn giải pháp cùng giá cả nhanh nhất có thể.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ