Introduction:

A plastic coating machine is a tool that adds a protective layer of plastic onto a surface. This machine has many advantages over traditional coating methods., we will discuss the advantages, innovation, safety, use, how to use, service, quality, and application of a Xinqinfeng plastic coating machine.

The plastic coating machine is an innovation in the field of coating technology. It offers several advantages, such as:

1. Durability - The plastic coating is an excellent protective layer that can withstand wear and tear. It makes the surface more durable and long-lasting.

2. Cost-effective - One of the significant advantages of the Xinqinfeng plastic coating spray machine is that it is cost-effective. It requires fewer materials and manpower than traditional coating methods.

3. Eco-friendly - The plastic coating material is environmentally friendly and does not harm the environment.

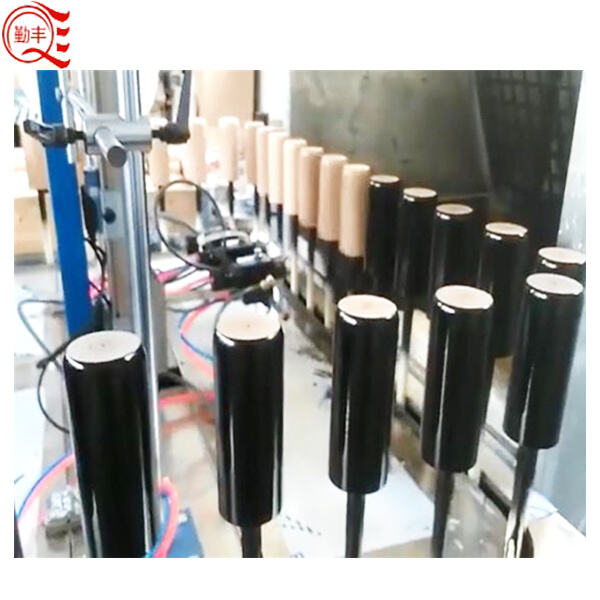

The plastic coating machine is an innovative tool that has revolutionized the coating industry. It makes coating faster and more efficient. The Xinqinfeng plastic painting machine is designed to make the coating process simple and easy.

The plastic coating machine is safe to use, and it is designed to reduce risks. The Xinqinfeng coating line comes with safety features that ensure the safety of the user and the equipment. Users should read the instruction manual carefully before using the machine.

The plastic coating machine can be used on a variety of surfaces. It can be used on metal, plastic, wood, and many other surfaces. The Xinqinfeng uv coating machine price is versatile and can be used for many different applications.

Xinqinfeng make use high-end materials and components for machine. They use first class metal components, imported spraying paint guns from top brands, best electronic brands, Taiwan brand PLC more.team of engineers and technicians have the experience ensure that each step the ideal solution.Xinqinfeng has good reputation customers,plastic coating machine,90% of our customers from overseas.

Xinqinfeng has been specialized in AUTO Coating machine over 20 years. can plastic coating machinethe Non-customized service,one stop coating service from cleaning,spraying,drying,metallic coating,powder coating etc.From production installation,paint,paint teacher,air compressor ,can Provide key services make customers more worry free achieve rapid mass production.

Xinqinfeng Factory has highly skilled engineers technicians with 20 years knowledge in powder coating liquid coating. have full ranges of plastic coating machineall types of items, from wooden to glass, cosmetic bottles more. For water-based paints like paints, vanish, UV paints, etc.

Xinqinfeng Specialized in the auto spray paint machine, full-auto spraying drying line, plastic coating machineoven, UV Curing furnace and PVD coating machine,Robot spraying line twenty years.Our machine has been exported to various countries, like North America, Europe South America, Middle Eastern, West African other countries. A lot of our machines CE Certification.

Using a plastic coating machine is easy. First, the user needs to prepare the machine by checking the equipment, materials, and the work area. Next, the user needs to load the material onto the machine. The user then needs to set the parameters for the coating, such as the thickness and the speed of the Xinqinfeng automatic uv spray coating line. After that, the user can start the machine and apply the coating. Finally, the user can check the quality of the coating and make any necessary adjustments.

The plastic coating machine requires occasional maintenance to ensure that it operates correctly. Users should follow the maintenance instructions provided in the manual. The manufacturer may also offer repair services of Xinqinfeng automatic uv spray coating machine.

The plastic coating machine provides high-quality coatings. The machine is designed to produce consistent coatings that are uniform in thickness and appearance. The Xinqinfeng brake pads powder coating line settings can be adjusted to achieve the desired quality of the coating.