Coating Machine: The Supreme Service for Quality Coverings

Intro

Coating devices are an ingenious innovation that was developed to deal a distinct and affordable technique of using coverings. The Xinqinfeng coating machine offers a number of advantages that makes it an important device different in markets. We'll check out the different elements and prominent functions of a coating machine, consisting of its own benefits, development, security, utilize, exactly how precisely to utilize, service, applications, and quality.

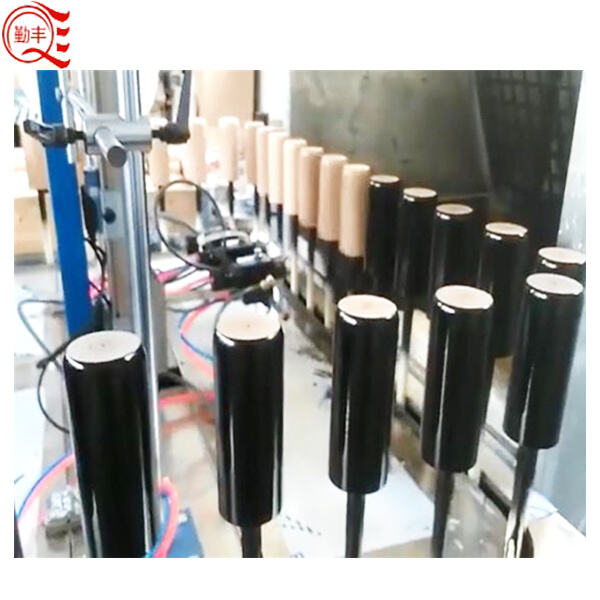

A coating machine offers several benefits that make it a popular tool in various industries. One of the most significant advantages of a Xinqinfeng coating spray machine is its efficiency. These machines are designed to apply coatings evenly and consistently, ensuring high-quality results. Additionally, coating machines are highly versatile and can be used to apply various types of coatings, including powder coatings, liquid coatings, and others.

The development of coating machines is the result of continuous research and innovation. The design and functionality of these machines are constantly being improved to provide better results and efficiency. Modern Xinqinfeng spray coating machine come with various features, including automated controls, multiple spray guns, multi-stage filtering systems, and others. These features are meant to enhance productivity, quality, and consistency.

Safety is a crucial aspect of the manufacturing process, and coating machines come with several safety features to ensure the health of operators. One of the most notable safety features is the use of advanced ventilation systems. These Xinqinfeng coating equipment systems help remove fumes and gases generated during the coating process, ensuring operators breathe in clean air. Additionally, coating machines feature safety interlocks that prevent the machine from operating when doors are open, thus preventing accidents.

Using a coating machine requires a certain level of knowledge and skill. The first step in using a Xinqinfeng automatic coating machine is selecting the type of coating to be applied. Once the coating is selected, you need to follow the manufacturer's instructions on how to prepare it. The next step is to prepare the surface to be coated, which involves cleaning the surface to remove any dirt or contaminants that may affect the quality of the coating.

The coating can then be applied using a coating machine. The operator should ensure that they adjust the machine's settings according to the manufacturer's specifications to ensure consistent and high-quality results. Once the coating has been applied, the operator should inspect the surface to ensure that the coating is evenly applied and that there are no defects.

Xinqinfeng a specialist in the AUTO Coating machine over 20 years. can offered the Non-customized service,one stop coating Coating machinecleaning,spraying,drying,metallic coating,powder coating etc.From production installation,paint,paint teacher,air compressor ,can Provide key services to make customers more worry free and achieve rapid mass production.

Xinqinfeng uses high-quality materials parts to make the machine. These include top of line metal Coating machineincluding imported spraying paint guns from Taiwan, best electronic brands Taiwan brand PLC.have skilled engineers and worker,to ensure every process is optimal, from design production.Xinqinfeng has good reputation in customers,nowadays,90% of our customers from overseas.

Xinqinfeng Specialized in the Auto Spray Paint Machine, full-auto spraying drying line,Industrial oven, UV Curing furnace PVD coating machine, Robot spraying paint line 20 years.machine been exported to many Coating machine,such as European,North America and South America, Middle East, West African other countries. Many machines have CE Certification.

Xinqinfeng Factory home to skilled engineers and employees with 20 years knowledge in liquid coating powder coating. have full ranges of machines suit all products, from wood to glass, Coating machinebottles, more. For paint water based paint, vanish,UV paint, etc.